Detection device for detecting electrical performance of electronic circuit board

A technology for electrical performance testing and electronic circuit boards, applied in electronic circuit testing, measuring devices, printed circuit testing, etc. The effect of facilitating batch operation and preventing missed detection and false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further technically described below with reference to the accompanying drawings and embodiments.

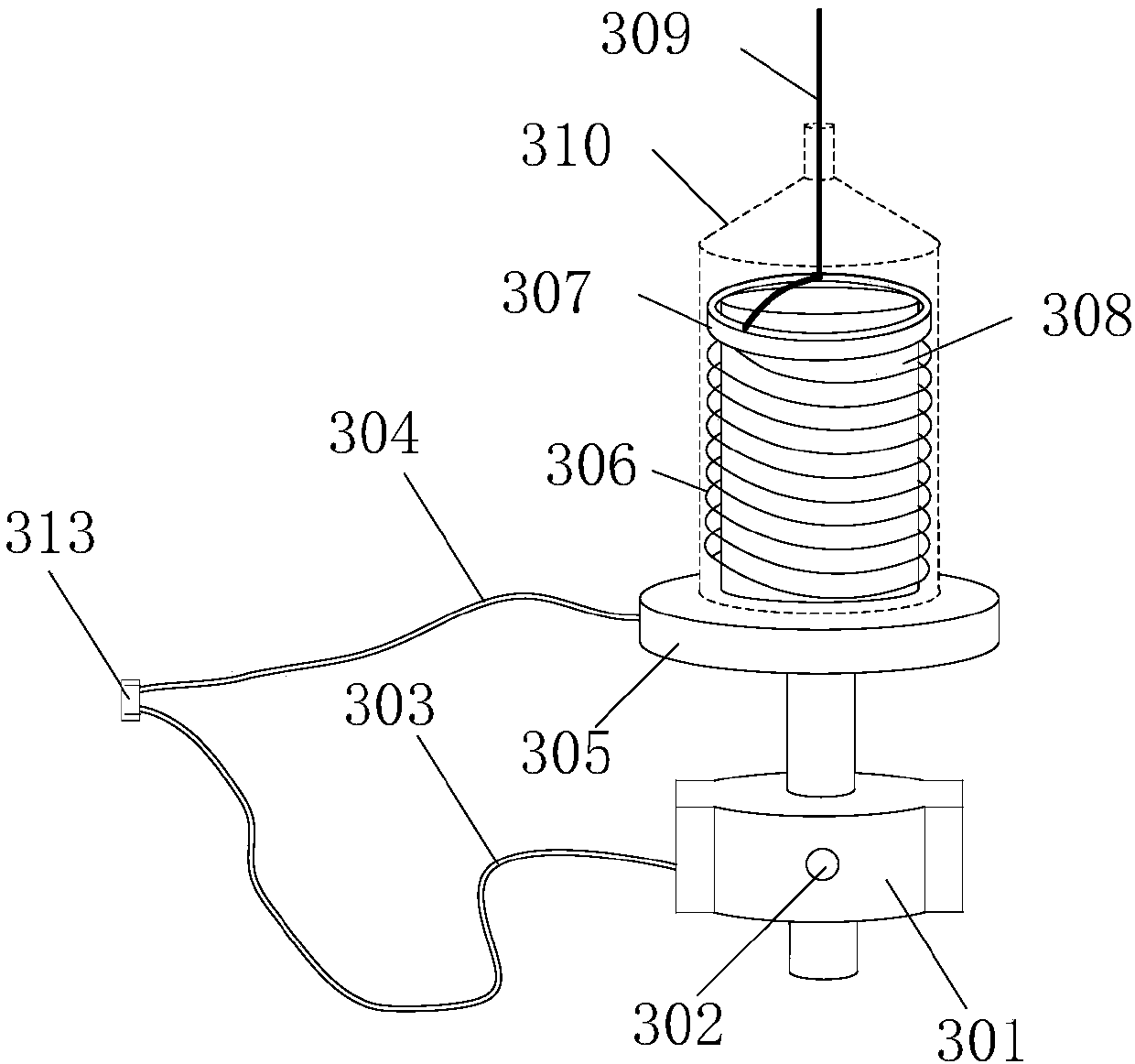

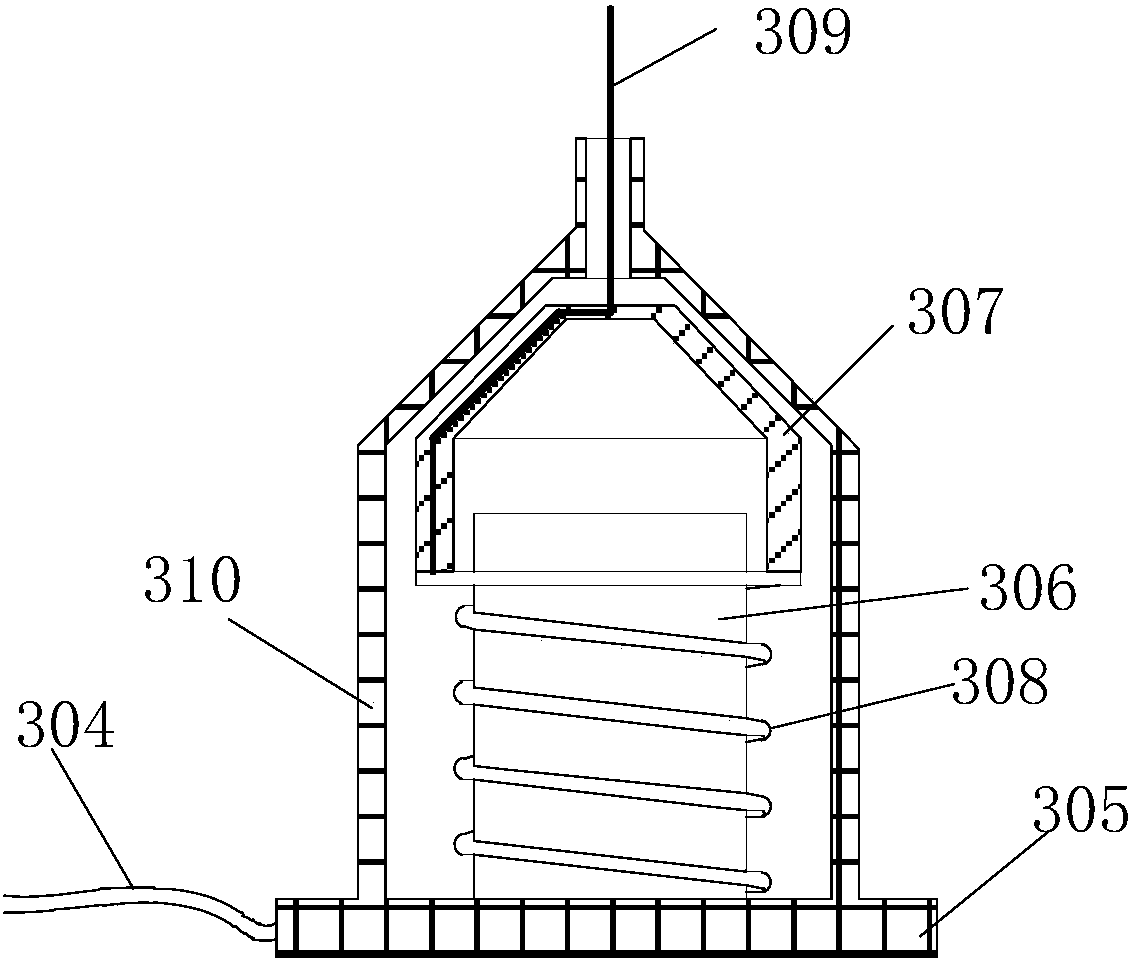

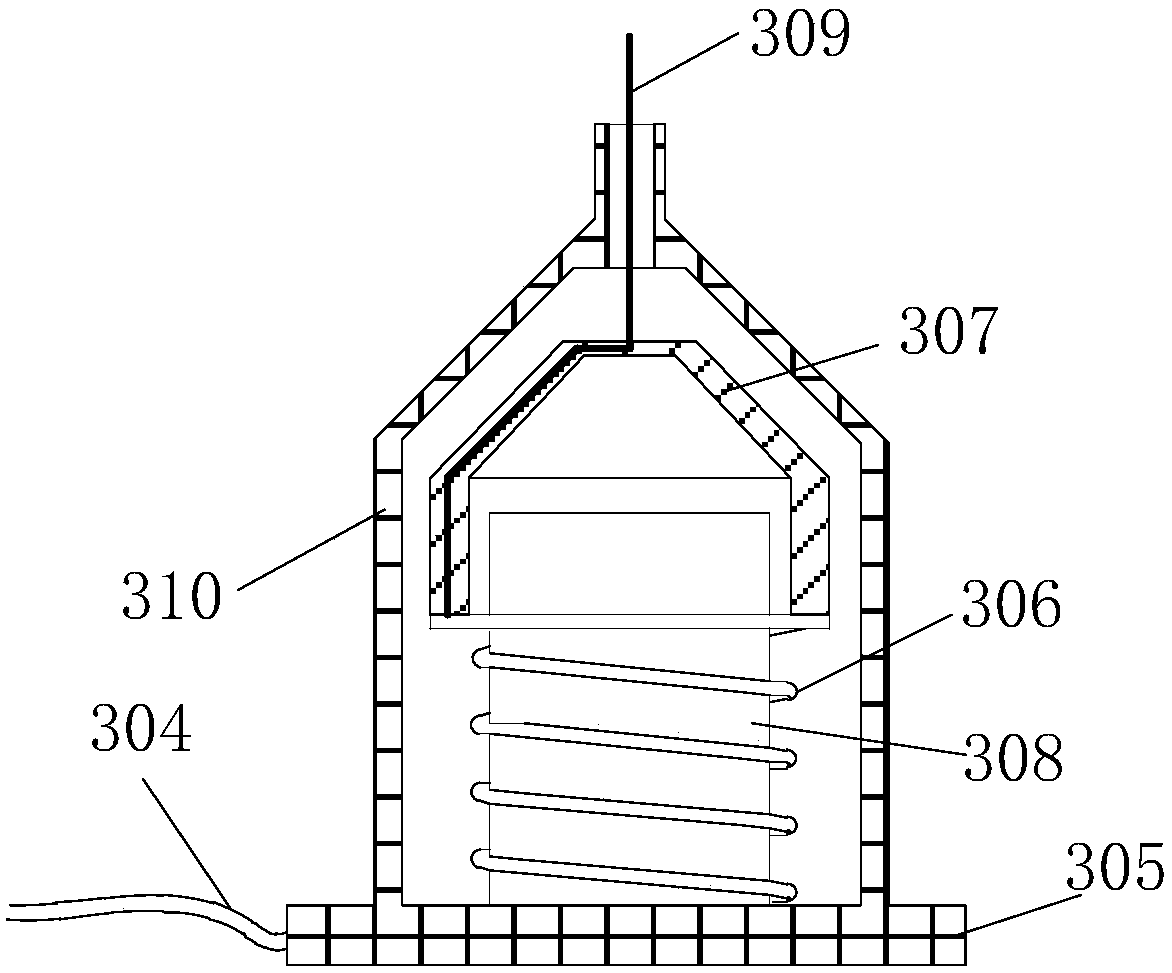

[0028] Such as Figure 1-9 Shown, a kind of electronic circuit board electrical property detection device comprises base 4, and base 4 is provided with support 5 perpendicular to base 4, and support 5 is fixed with bracket 2 parallel to base 4; 311 is fixed on a plurality of probes 3 on the substrate 1, and the probes 3 include a push mechanism at the bottom and a detection mechanism at the top; the push mechanism includes a linear motor 301, and the outer wall of the motor 301 is provided with a positioning hole 302; the motor 301 drives the push mechanism The rod reciprocates, the top of the push rod is provided with a circular tray 305, the center of the tray 305 is fixed with a guide post 308, and a spring 306 is nested on the guide post 308, and the bottom end of the spring 306 is connected to the second cable 304 through the wire built i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com