Printed circuit board (PCB) design method for preventing electromagnetic interference (EMI)

A PCB board, design method technology, applied in the direction of crosstalk/noise/electromagnetic interference reduction (, circuit devices, printed circuit components, etc., can solve the problems of wasting assembly time, products with EMI grounding points, few contact points, etc., Achieve the effect of solving the EMI problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

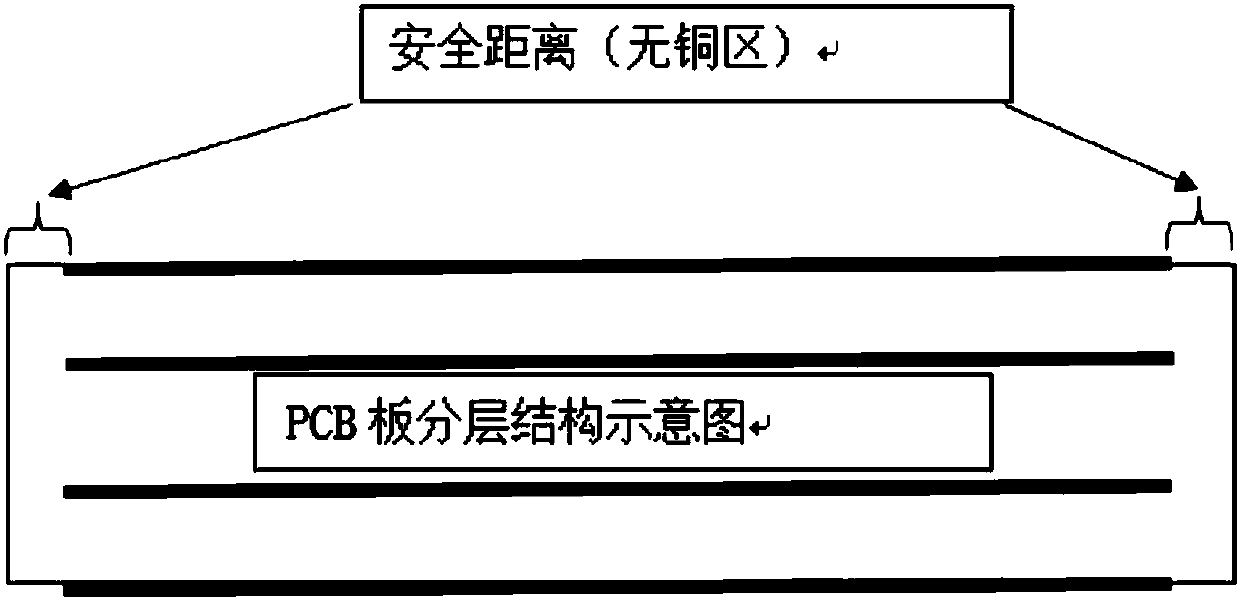

[0018] as attached figure 1 As shown, the metal shell electronic products in the prior art are usually fixed by locking screws when assembling the PCB, and in order to prevent short circuit caused by copper leakage at the edge of the PCB, the edge of the PCB, whether it is the inner layer or the outer layer, cannot With copper foil. Therefore, the current PCB design needs to keep a safe distance.

[0019] as attached figure 2 As shown, the existing PCB board fixing method is to lock the screw and fix it by locking the screw.

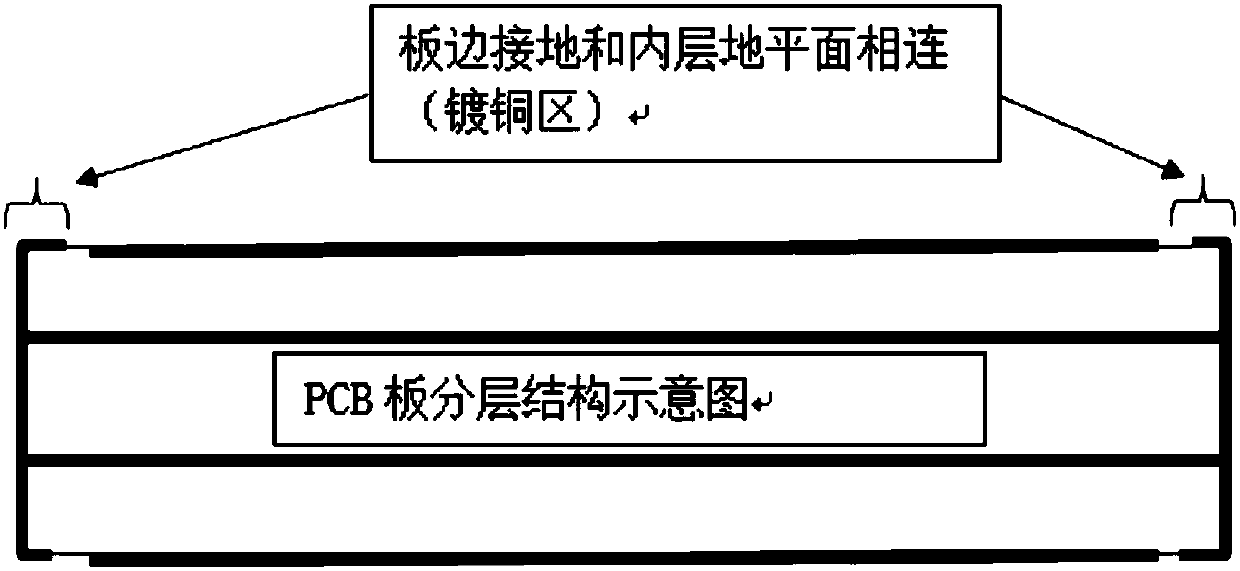

[0020] In the present invention, grounding copper is leaked from the edge of the PCB board, and the copper plating on the edge of the board is grounded. When assembling, the copper plating on the edge of the board and the metal casing are directly contacted and clamped to achieve the purpose of direct fixing, which not only saves the time of locking screws but also can It has a better effect of preventing EMI.

[0021] The specific implementation st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com