Artificial turf system

A technology of artificial turf and artificial grass, which is applied in the field of improved filling materials and filling turf systems, and can solve the problems of failure to achieve the best quality natural grass field performance and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

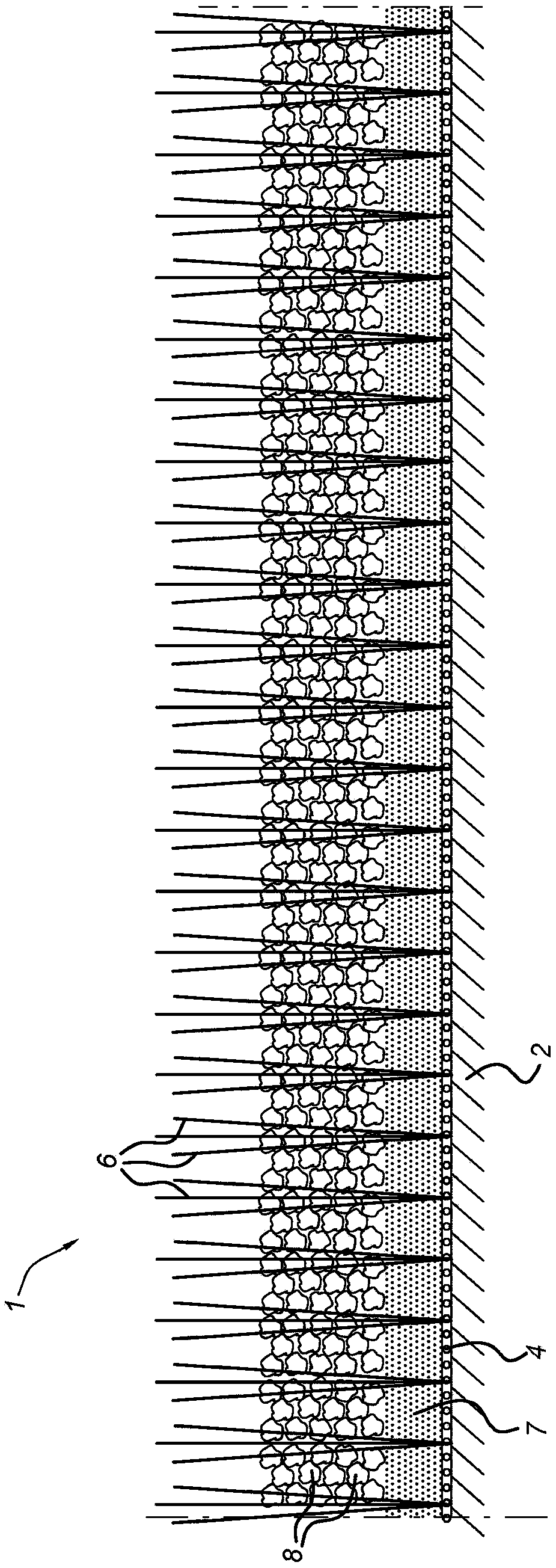

[0030] figure 1 A cross-section of a conventional artificial turf system 1 is shown, comprising a stable base 2 , a base plate 4 , pile fibers 6 and a filling 8 formed of elastomeric rubber particles and a sand layer 7 . Substrate 4 and fluff fibers 6 are from Greenfields TM Slidemax 60 TM Tufted grass system and DS XWR TM Down fiber6. The sand layer 7 is 15mm and the fill 8 has an undefined shape with a Shore A hardness of 60-65 and a grain size of 0.8mm-2.5mm. Turf System 1 of Example 1 is believed to represent the best state of the art artificial turf systems currently available for foot release and slide performance purposes.

Embodiment 2

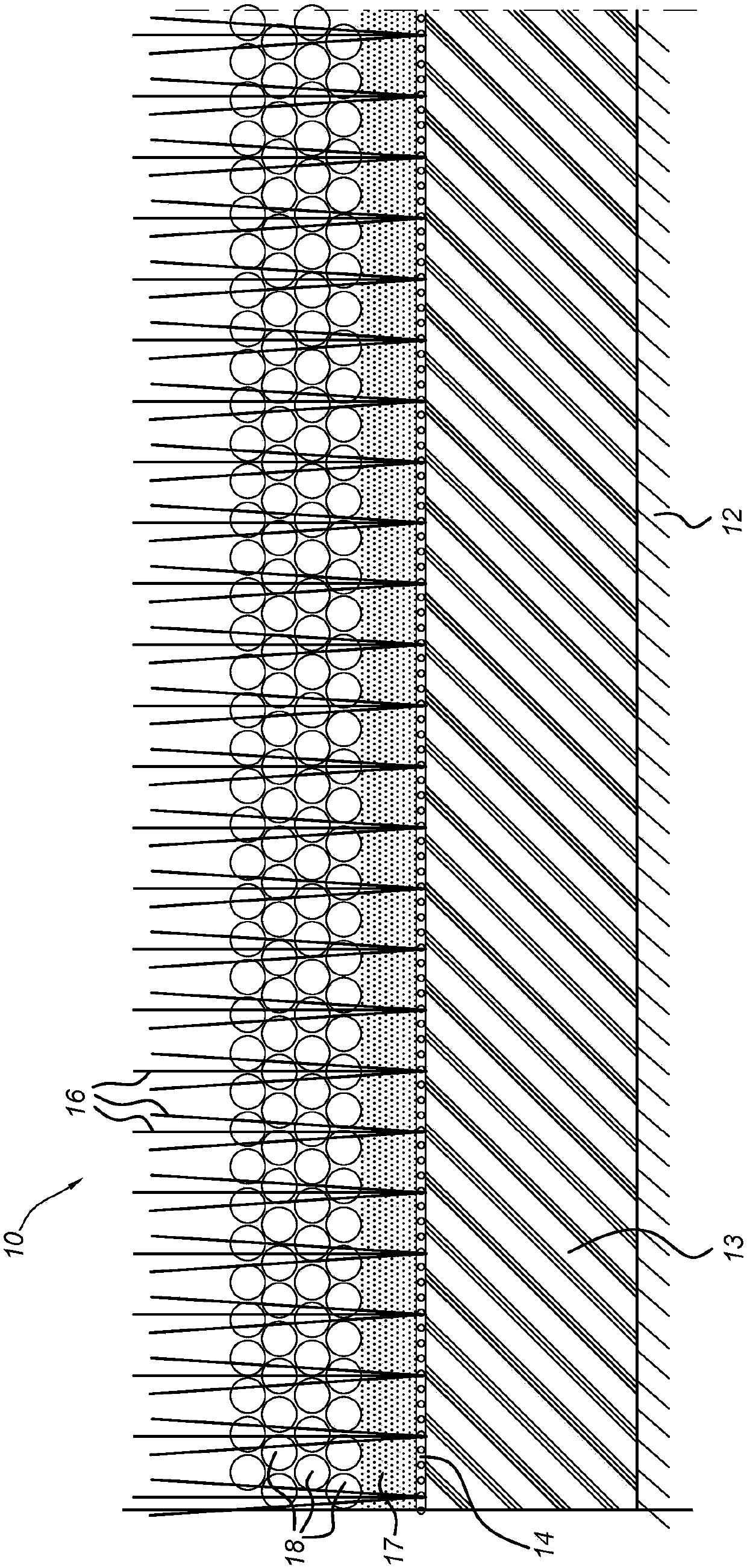

[0032] figure 2 A cross-section of an artificial turf system 10 according to one embodiment of the invention is shown. The turf system 10 includes a stable base 12 , a resilient layer 13 , a substrate 14 with fluff fibers 16 , a granule layer 17 and a fill layer 18 . According to an embodiment, the elastic layer 13 is Ecocept TM 40mm layer, containing 60% rubber and 40% recycled plastic granules with 14wt.% PU binder. The artificial grass layer was Woven Carpet MX from Greenfields, 50 mm Trimension fibers with fibers of diamond cross section. The fine grain layer 17 is 10mm sand filling, grade 0.2-1.0mm, with 15kg / m 2 Coverage. The packing layer is composed of PE fine particles at a depth of 25mm, with a Shore D hardness of 40, good roundness, with medium sphericity, 3.8mm average diameter and 12.5kg / m 2 Coverage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com