Material scraping device for cement barrel

A cement and scraper technology, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of being fixed on the barrel wall, difficult to clean and remove, and concrete adhesion, etc., to reduce time costs. , The effect of protecting the surface quality and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

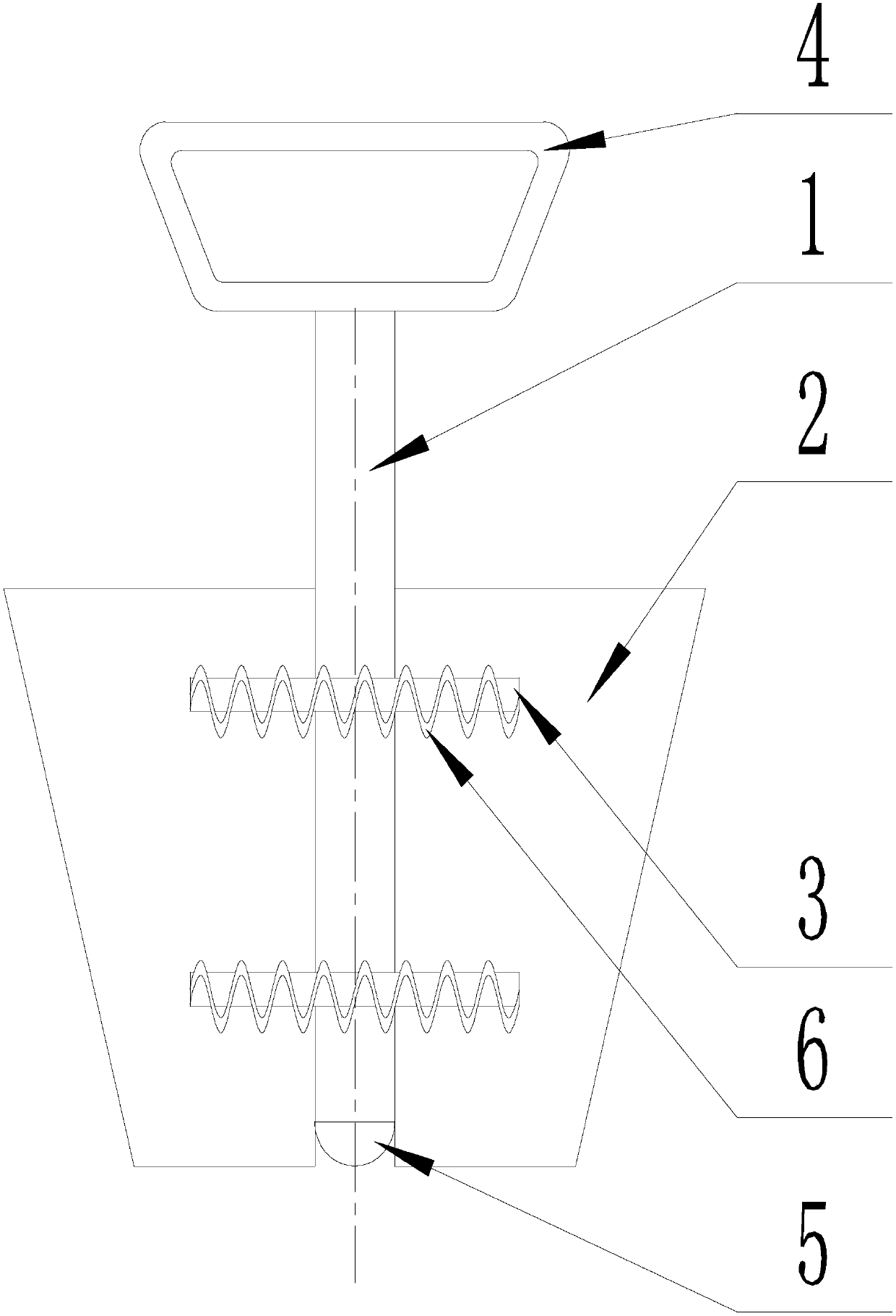

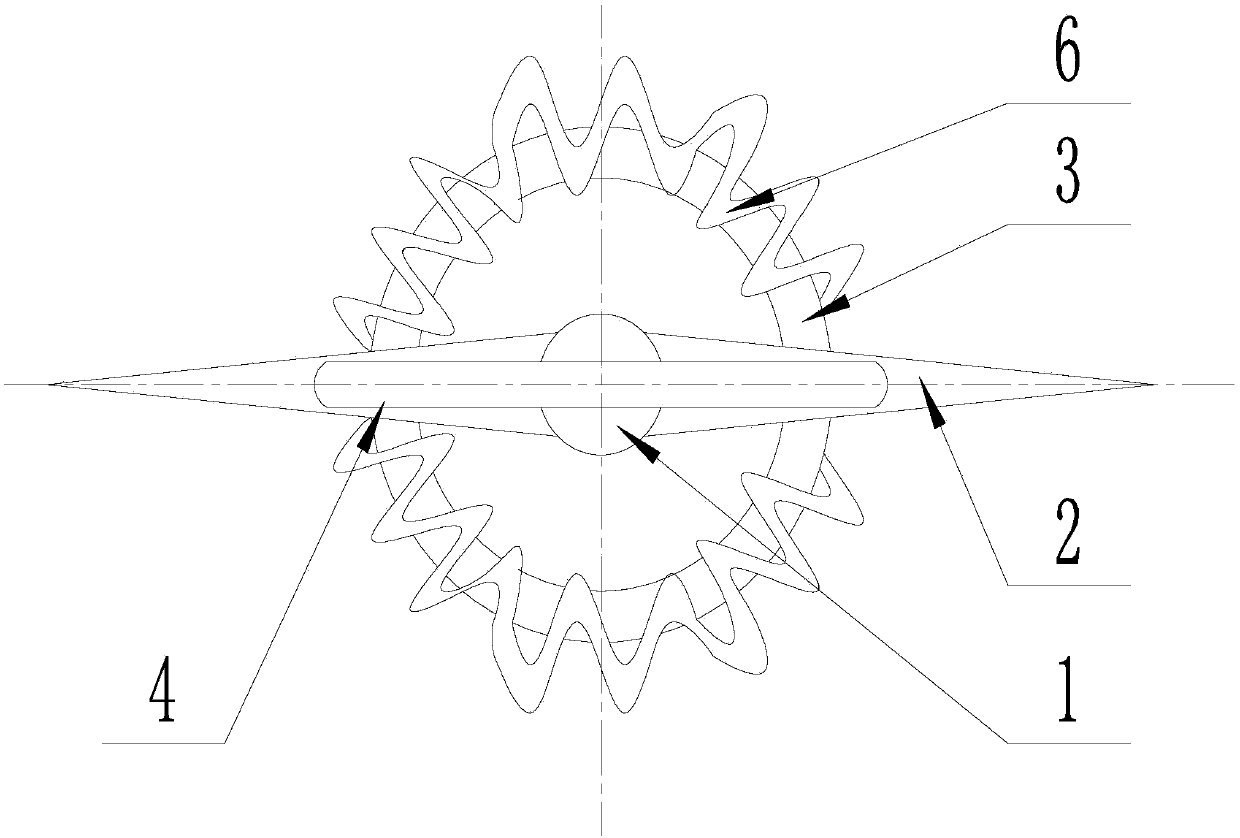

[0030] Such as Figure 1-Figure 2 As shown, the scraper device for cement barrels of the present invention includes a connecting shaft 1, and two scrapers 2 are arranged on the side wall of the connecting shaft 1, and the scrapers 2 are all parallel to the axis of the connecting shaft 1, scraping The boards 2 are all right-angled trapezoids, and their upper and lower bases are perpendicular to the axis of the connecting shaft 1, and their straight waistlines are connected to the connecting shaft 1, and the scrapers 2 are symmetrically arranged on the connecting shaft along the axis of the connecting shaft 1. 1 on;

[0031] A support rod 3 is arranged between the two scrapers 2, and the support rod 3 is bent into an arc shape, and its ends are respectively connected to a scraper 2, and the bending axis of the support rod 3 coincides with the axis of the connecting shaft 1;

[0032] A spring 6 is sheathed on the support rod 3, and the spring is a cylindrical helical spring, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com