Device for adjusting bearing clearance and main shaft

A technology for adjusting bearings and clearances, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of abnormal spindle operation, low cost requirements, bearing damage, etc., to ensure reliability and stability, and protect the Damaged, the effect of ensuring the accuracy of the fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

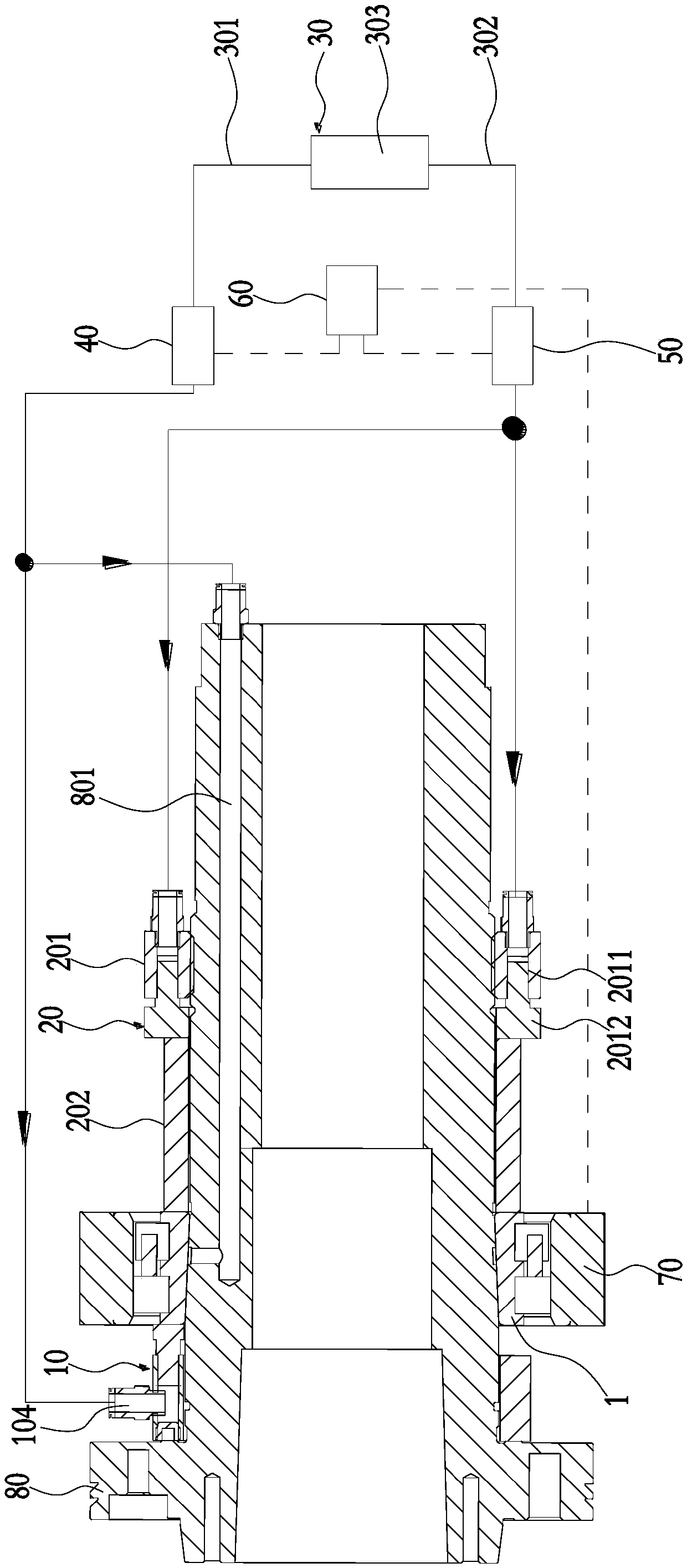

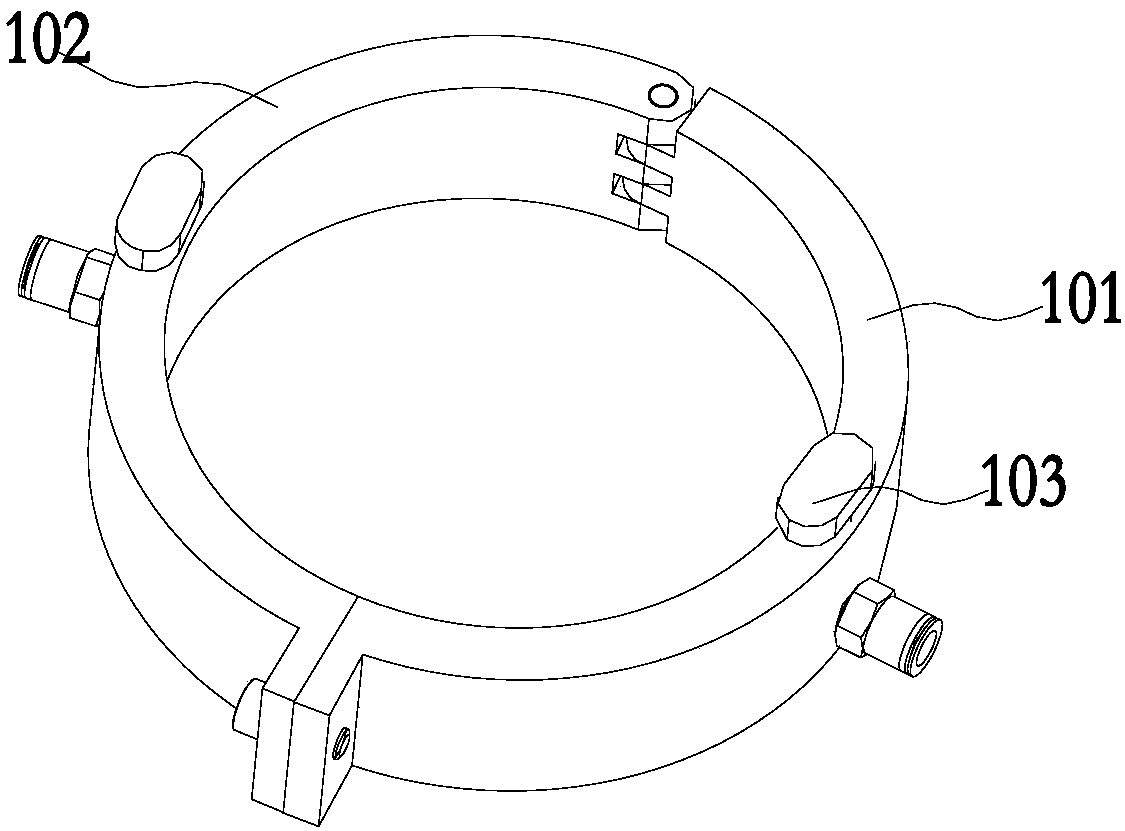

[0019] Such as figure 1 As shown, a device for adjusting bearing clearance includes a first pressing assembly 10, a second pressing assembly 20 and a hydraulic drive assembly 30. The first pressing assembly 10 has a first pressing portion for contact with the bearing 1 The inner ring at one end presses against each other, and the second pressing assembly 20 has a second pressing portion for pressing against the inner ring at the other end of the bearing 1. The hydraulic drive assembly 30 is connected with the first pressing assembly 10 and the second pressing assembly 10 respectively. The pressing assembly 20 is connected by transmission.

[0020] On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com