Construction method for excavating straight wall of rock deep foundation pit

A construction method and technology for deep foundation pits, which are applied in excavation, infrastructure engineering, construction, etc., can solve the problems of increasing the excavation range, increasing construction costs, and increasing the amount of backfilling, so as to reduce the amount of excavation engineering and reduce the amount of backfilling. The effect of reducing the amount of backfill usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

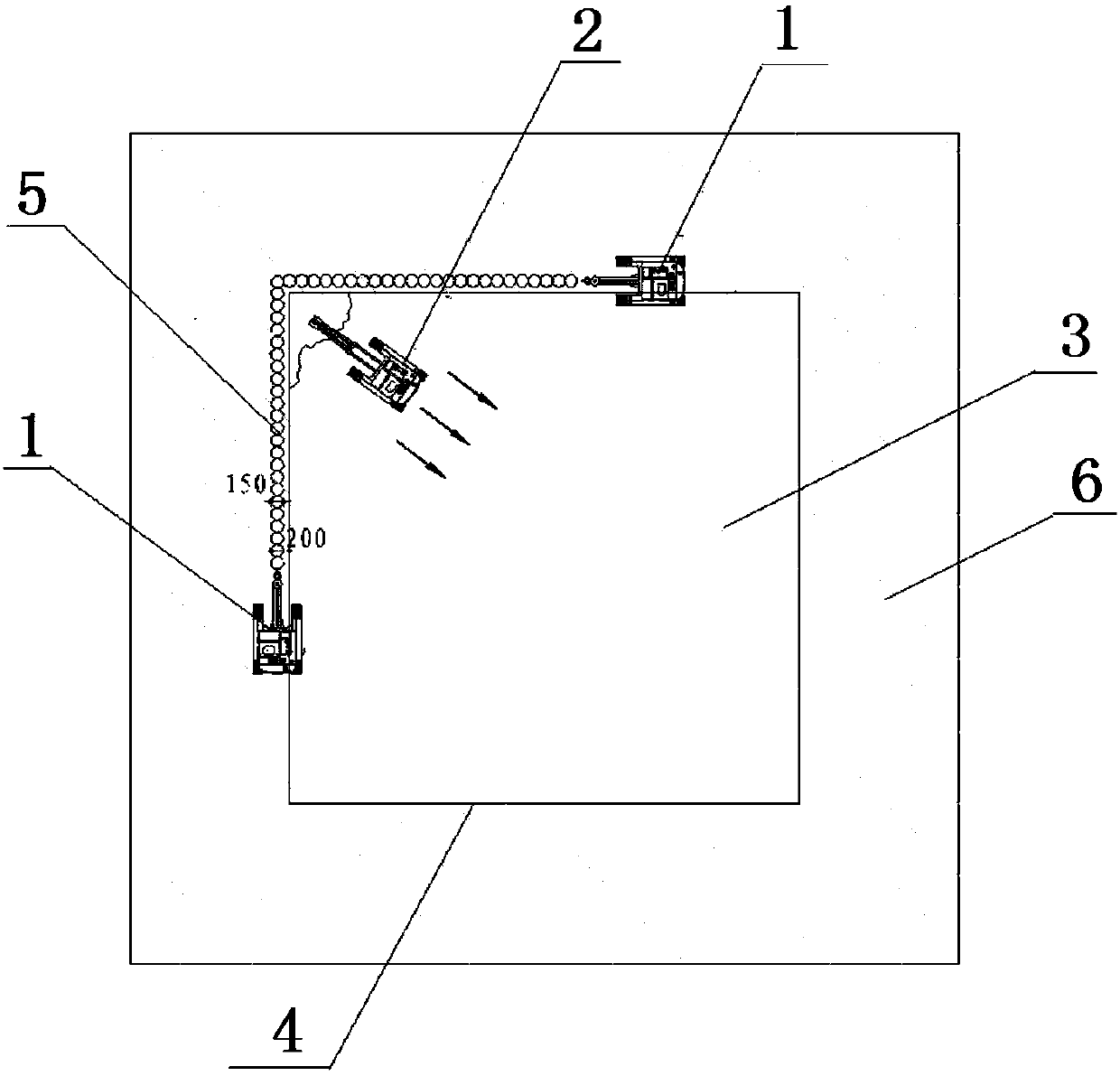

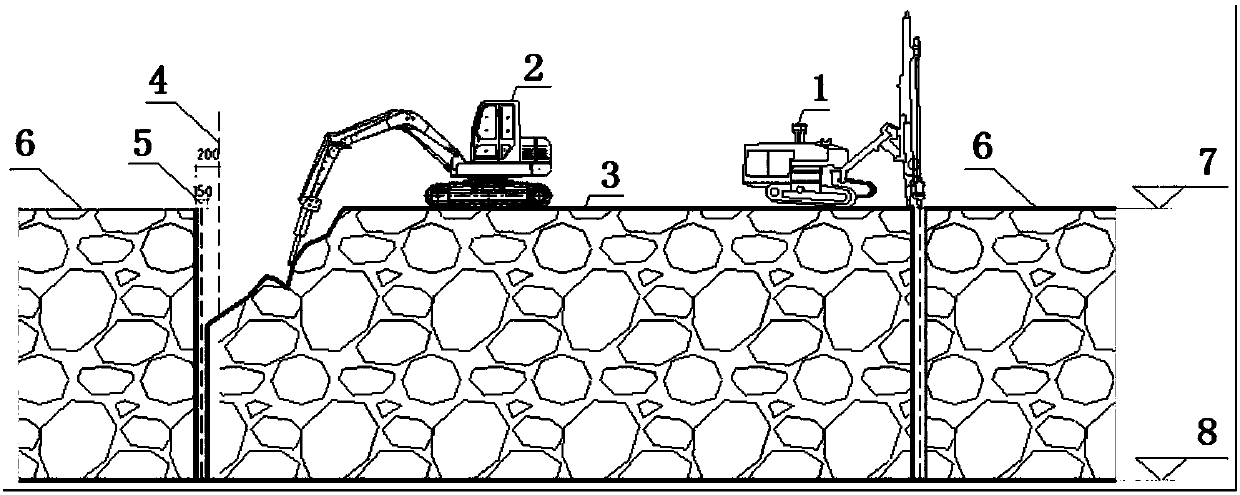

[0023] Embodiments of the invention: see figure 1 and figure 2 , the present invention is a kind of construction method that is used for the straight wall excavation of rock deep foundation pit, comprises the following steps:

[0024] Step 1. Sampling the excavation site to determine the range of rock hardness. The construction method of the present invention can be used within the scope of secondary hard rock, common hard rock and extra hard rock in the Platts Classification Table of Rock and Soil, and determine each hardness range in conjunction with the construction drawings. Excavation depth and scope of excavation in the area;

[0025] Step 2. Leveling the area to be excavated, and controlling the slope of the working surface within 1-10°;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com