All-solid-state battery mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

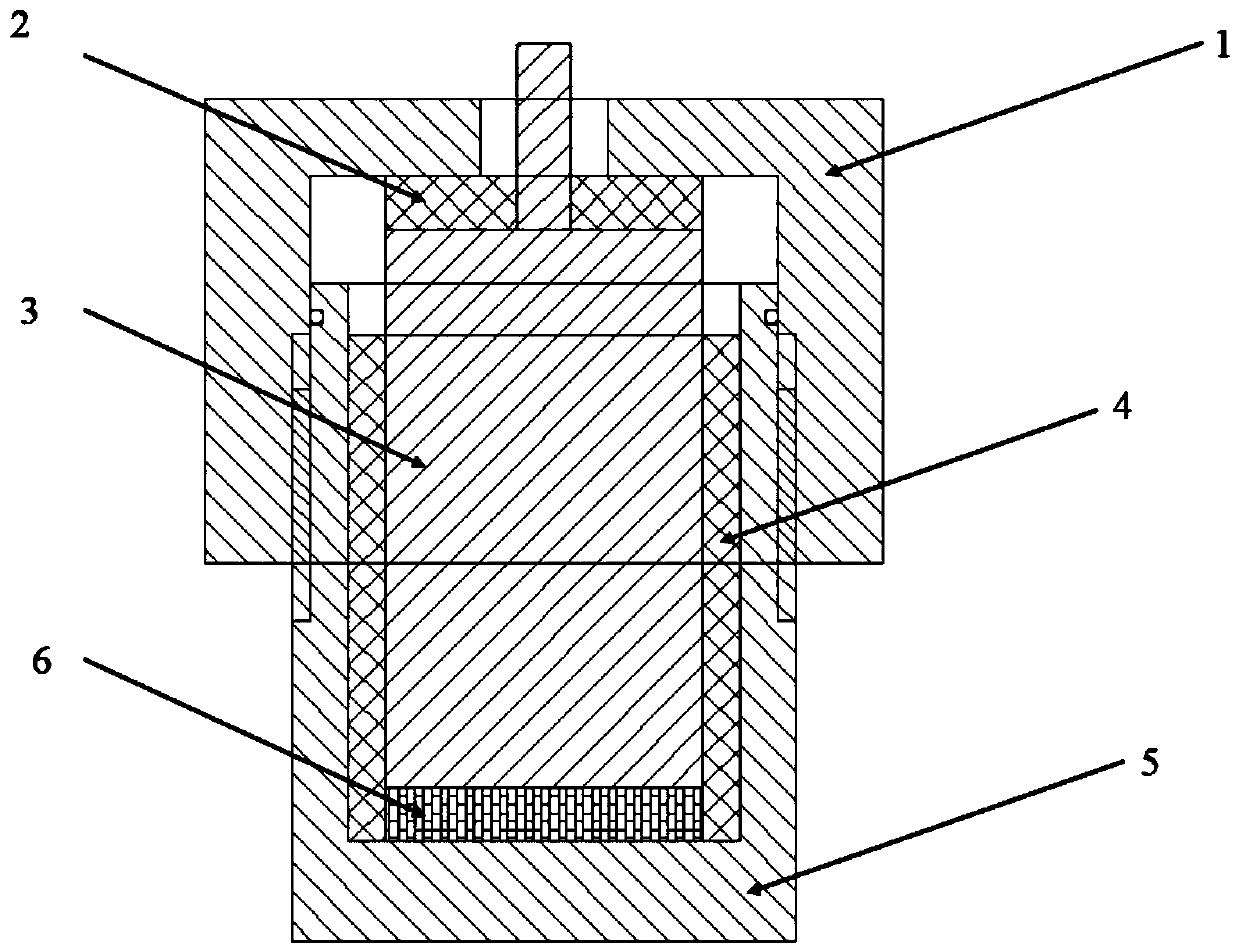

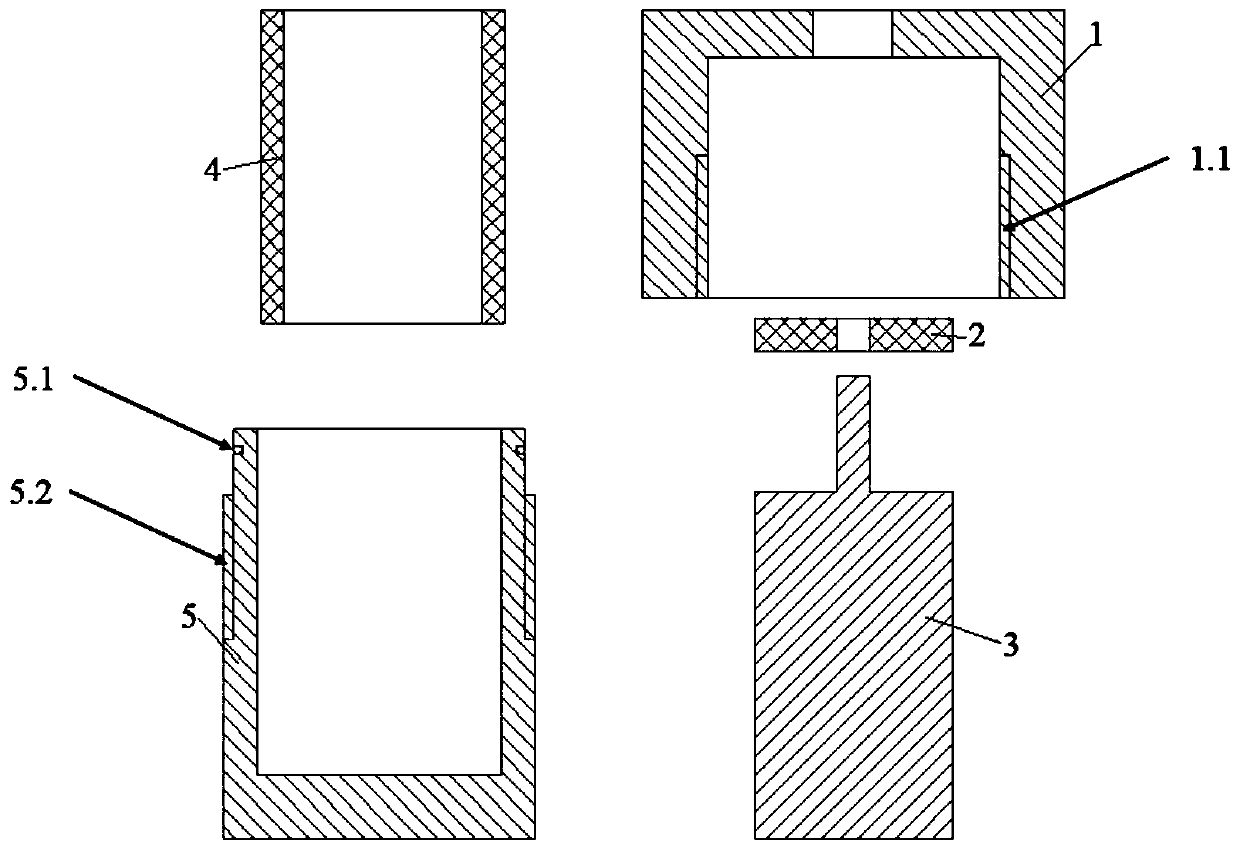

[0019] Such as figure 1 and figure 2 As shown, an all-solid-state battery mold, the mold includes a barrel-shaped internal thread aluminum alloy part 1, a barrel-shaped external thread aluminum alloy part 5, a rod-shaped aluminum alloy part 3 with external leads, and a polytetrafluoroethylene insulating gasket 2 And polytetrafluoroethylene insulating sleeve 4. Among them, 1.1 is the internal thread, 5.2 is the corresponding external thread, and 5.1 is the sealing ring. The other 6 is the positive electrode, electrolyte and negative electrode of the all-solid-state battery. The barrel-shaped internal thread aluminum alloy part 1 and the barrel-shaped external thread aluminum alloy part 5 are connected by threads, and the barrel-shaped external thread aluminum alloy part 5 is put into the rod-shaped aluminum alloy part 3 connected with the external lead wire. The threaded aluminum alloy part 5 and the rod-shaped aluminum alloy part 3 connected to the external lead wire are i...

Embodiment 2

[0022] Such as figure 1 and figure 2 As shown, an all-solid-state battery mold, the mold includes a barrel-shaped internal thread aluminum alloy part 1, a barrel-shaped external thread aluminum alloy part 5, a rod-shaped aluminum alloy part 3 with external leads, nylon insulating gasket 2 and nylon insulating Casing 4. Among them, 1.1 is the internal thread, 5.2 is the corresponding external thread, and 5.1 is the sealing ring. Among them, 6 are the positive electrode, electrolyte and negative electrode of the all-solid-state battery. The barrel-shaped internal thread aluminum alloy part 1 and the barrel-shaped external thread aluminum alloy part 5 are connected by threads, and the barrel-shaped external thread aluminum alloy part 5 is put into the rod-shaped aluminum alloy part 3 connected with the external lead wire. The threaded aluminum alloy part 5 is insulated from the rod-shaped aluminum alloy part 3 connected to the external lead wire by nylon insulating sleeve 4, ...

Embodiment 3

[0025] Such as figure 1 and figure 2 As shown, an all-solid-state battery mold, the mold includes a barrel-shaped internal thread stainless steel part 1, a barrel-shaped external thread stainless steel part 5, a rod-shaped stainless steel part 3 with external leads, nylon insulating gasket 2 and nylon insulating sleeve 4 . Among them, 1.1 is the internal thread, 5.2 is the corresponding external thread, and 5.1 is the sealing ring. Among them, 6 are the positive electrode, electrolyte and negative electrode of the all-solid-state battery. The barrel-shaped internal thread stainless steel part 1 and the barrel-shaped external thread stainless steel part 5 are connected by threads, and the barrel-shaped external thread stainless steel part 5 is put into the rod-shaped stainless steel part 3 with external lead wires, and the barrel-shaped external thread stainless steel part 5 It is insulated with the rod-shaped stainless steel part 3 of the external lead wire with a nylon in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap