A maker machine to manufacture hygiene absorbent articles

A technology for hygienic absorption and manufacturing machines, which is applied in the fields of absorbent pads, conveyor objects, medical science, etc., and can solve the problems of long and complicated replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

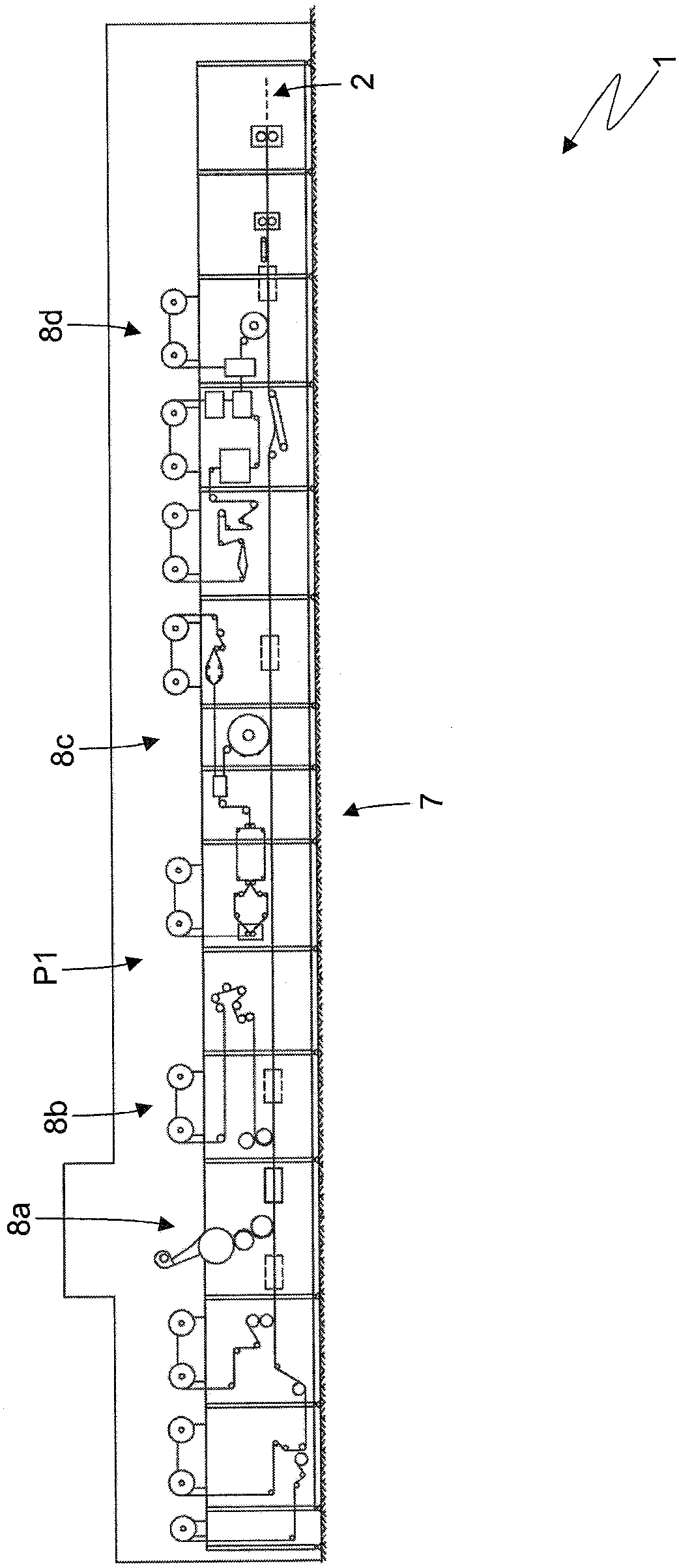

[0027] exist figure 1 , numeral 1 denotes an overall manufacturing machine for manufacturing hygienic absorbent articles 2 (eg, diapers).

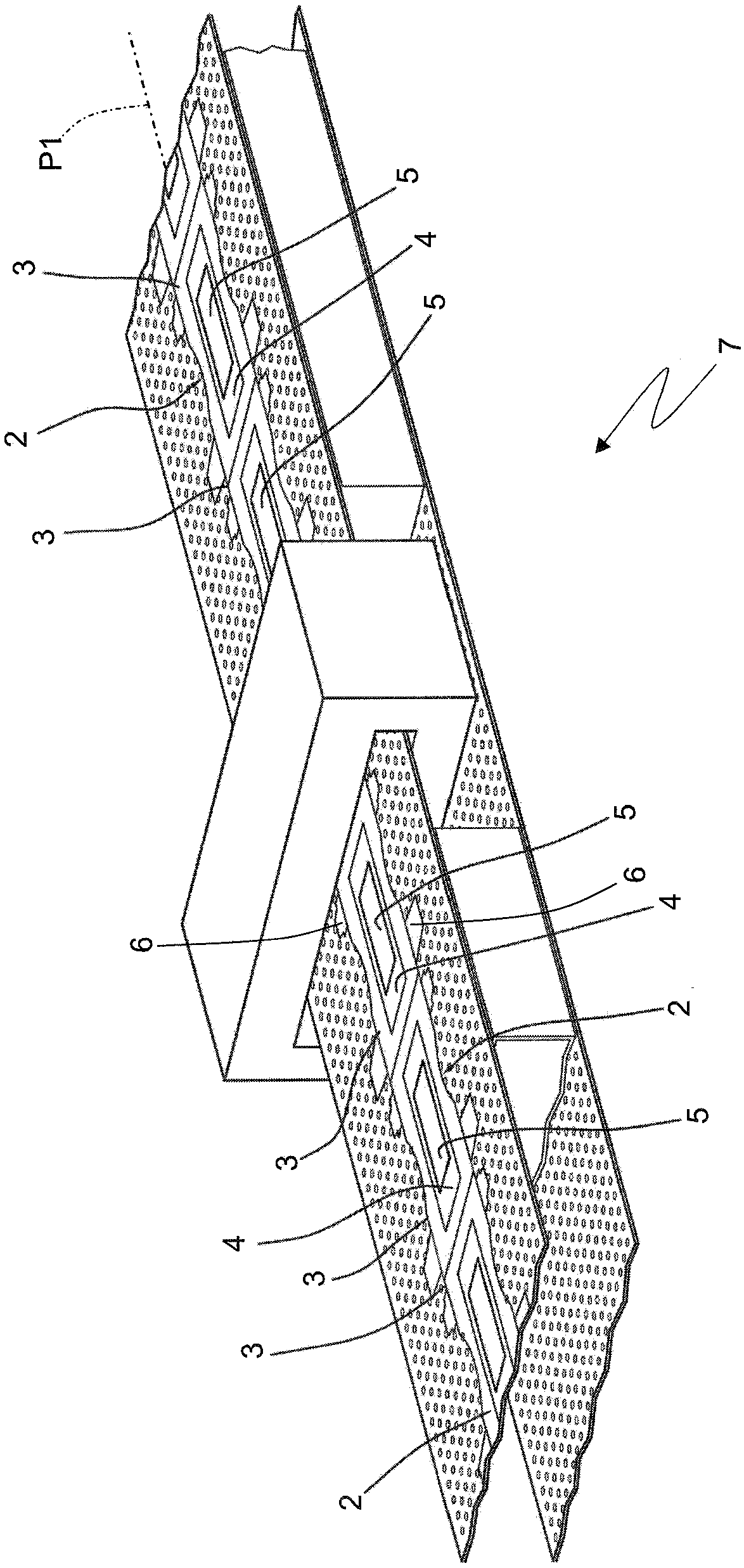

[0028] Such as figure 2 As shown, each sanitary absorbent article 2 comprises a sheet 3 of impermeable material (e.g., polyethylene) and a sheet 4 of permeable material (e.g., a "nonwoven") with an absorbent pad 5 enclosed therebetween, said absorbent pad Forms part of a sanitary absorbent article 2 for absorbing organic liquids. The absorbent pad 5 is typically, but not necessarily, formed from a homogenous mixture of natural fiber material ("fluff") and superabsorbent polymer material ("SAP"). Additionally, to increase absorbency, the pad 5 may also contain discrete layers of superabsorbent polymer material ("SAP") defining additional absorbent material; preferably, the superabsorbent polymer material is particulate superabsorbent polymer Material. Each sanitary absorbent article 2 also comprises two pairs of side flaps 6 extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com