Control method and control unit of driving circuit of electric vehicle as well as electric vehicle

A control method and technology of a control unit are applied in the control of electric vehicle drive circuits and in the field of electric vehicles, which can solve problems such as rising costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

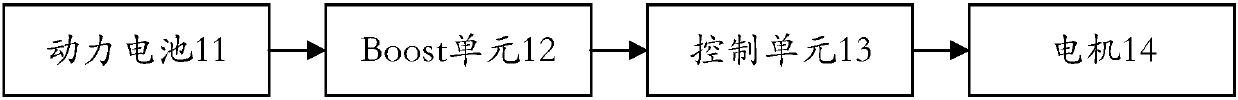

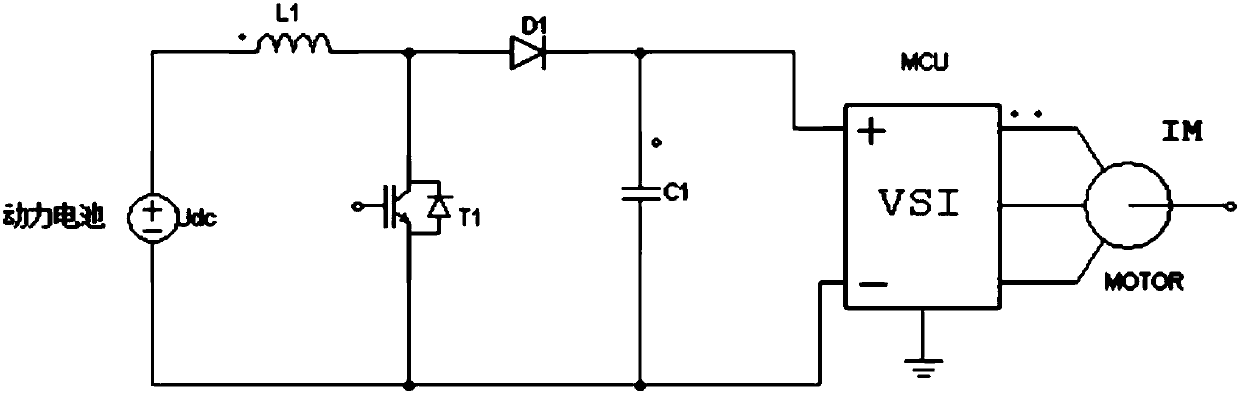

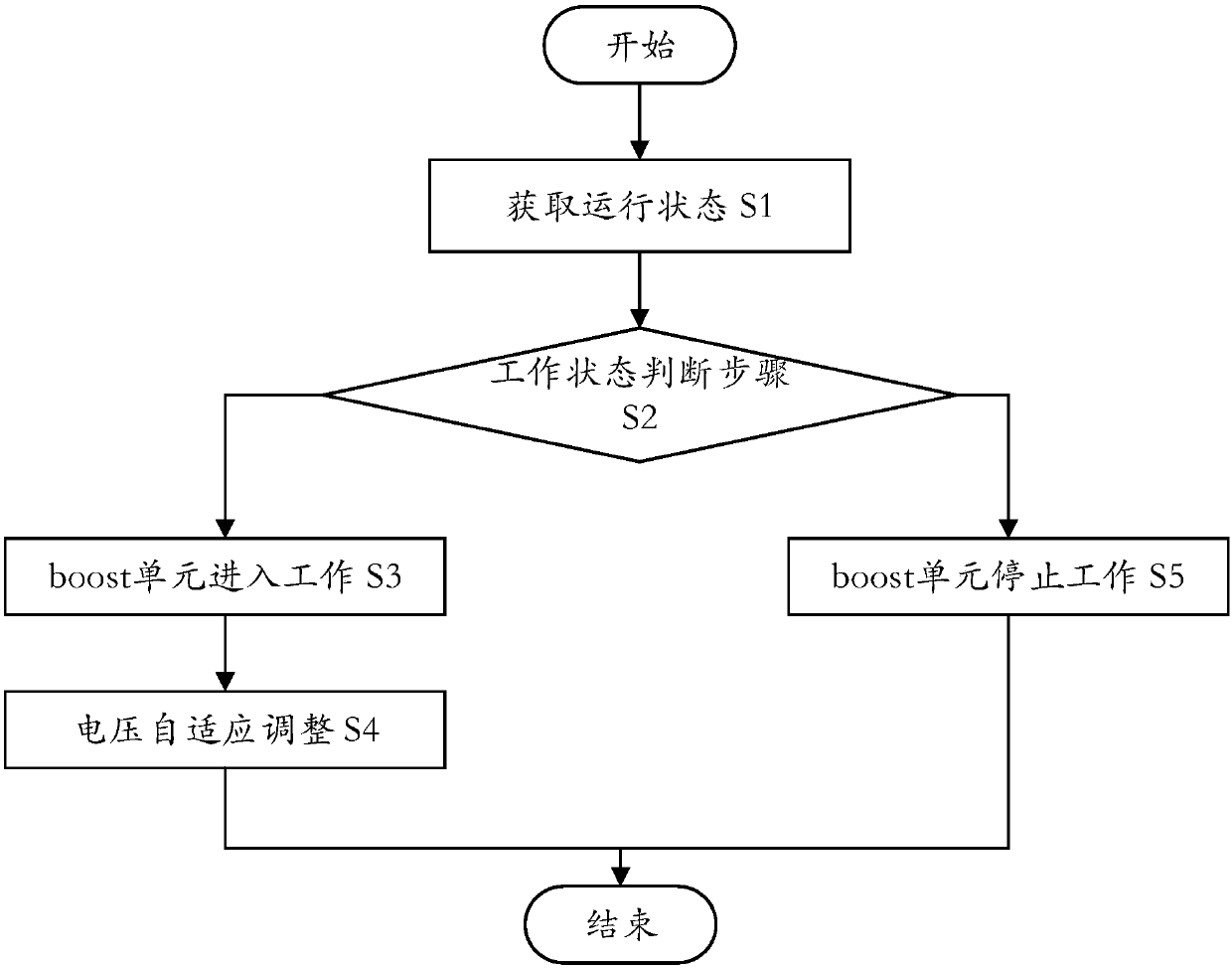

[0031] refer to figure 1 and figure 2 The electric vehicle includes a power battery, a drive circuit and a motor. The drive circuit includes a boost unit and a control unit. The control unit uses an MCU processor. The boost unit is used to receive the output voltage of the power battery and output a boosted voltage to the motor. The boost unit outputs control signals. The boost unit includes an inductor L1, a switching device T1, a diode D1, and a capacitor C1. The switching device T1 can be a MOSFET or an IGBT tube. The first end of the inductor L1 is connected to the positive pole of the power battery 11, and the second end of the inductor L1 is connected to the switching device T1. The first end of the switching device T1 is connected to the anode of the diode D1, the cathode of the diode D1 is connected to the first end of the capacitor C1, and the second end of the switching device T1 is connected to the negative electrode of the power battery 11 and the second end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com