Roller type blister packaging machine

A blister packaging machine, roller-type technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as unfavorable machine maintenance, high packaging production costs, and reduced product quality, and achieve simple structure and high production efficiency High efficiency, easy operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in combination with the accompanying drawings and specific embodiments.

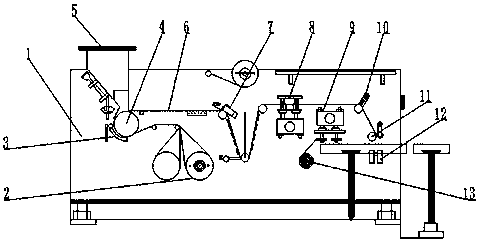

[0014] Such as figure 1 As shown, a roller-type blister packaging machine is mainly composed of a body 1, a thin film roll 2, a far-infrared heater 3, a forming device 4, a hopper 5, a monitoring platform 6, a heat-sealing device 7, a typing device 8, The blanking device 9, the adjustable guide roller 10, the intermittent feed roller 11, the conveyor 12 and the waste roller 13 are characterized in that a hopper 5 is arranged on the upper left of the body 1, and the forming device 4 is connected to the lower part of the hopper 5, The lower left side of the molding device 4 is provided with a far-infrared heater 3, the right side of the molding device 4 is provided with a monitoring platform 6, the thin film reel 2 is provided below the monitoring platform 6, and the right side of the monitoring platform 6 is provided with a heat sealing device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com