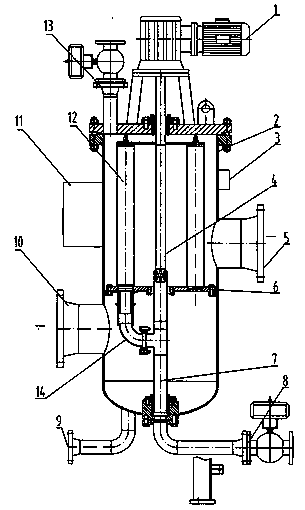

Filter with multiple filter elements

A filter and filter element technology, which is applied to fixed filter element filters, membrane filters, filtration separation, etc., can solve the problems of low dirt holding capacity, high maintenance cost, and easy clogging of filter elements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Describe embodiment in detail in conjunction with accompanying drawing, the present invention is the improvement to prior art, and it comprises a multi-element filter, on the top cover of filter, a motor 1 is installed with support, on the motor shaft through support and The top cover is installed with a rotating shaft 4 along the central axis of the filter housing 2. The lower end of the rotating shaft seals and rotates through the filter element mounting plate 6. A backwash pipe 7 that rotates with the rotating shaft is connected downward with a tee in the middle of the liquid inlet chamber. Connect a bypass pipe 14 on the bypass of the tee, which can be docked with any filter element 12 connection hole on the mounting plate with a suction cup, and a blowdown valve 8 is connected to the lower end of the backwash pipe to rotate and seal and cooperate with the downward head. , a manual drain valve 9 is installed on the other side of the drain valve on the lower head, a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com