Back-flushing pre-filter

A pre-filter and backwashing technology, applied in the field of water treatment, can solve the problems of easy blockage of the filter element, time-consuming and labor-intensive, secondary pollution, etc., and achieve the effects of beautiful appearance, reasonable technical design and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

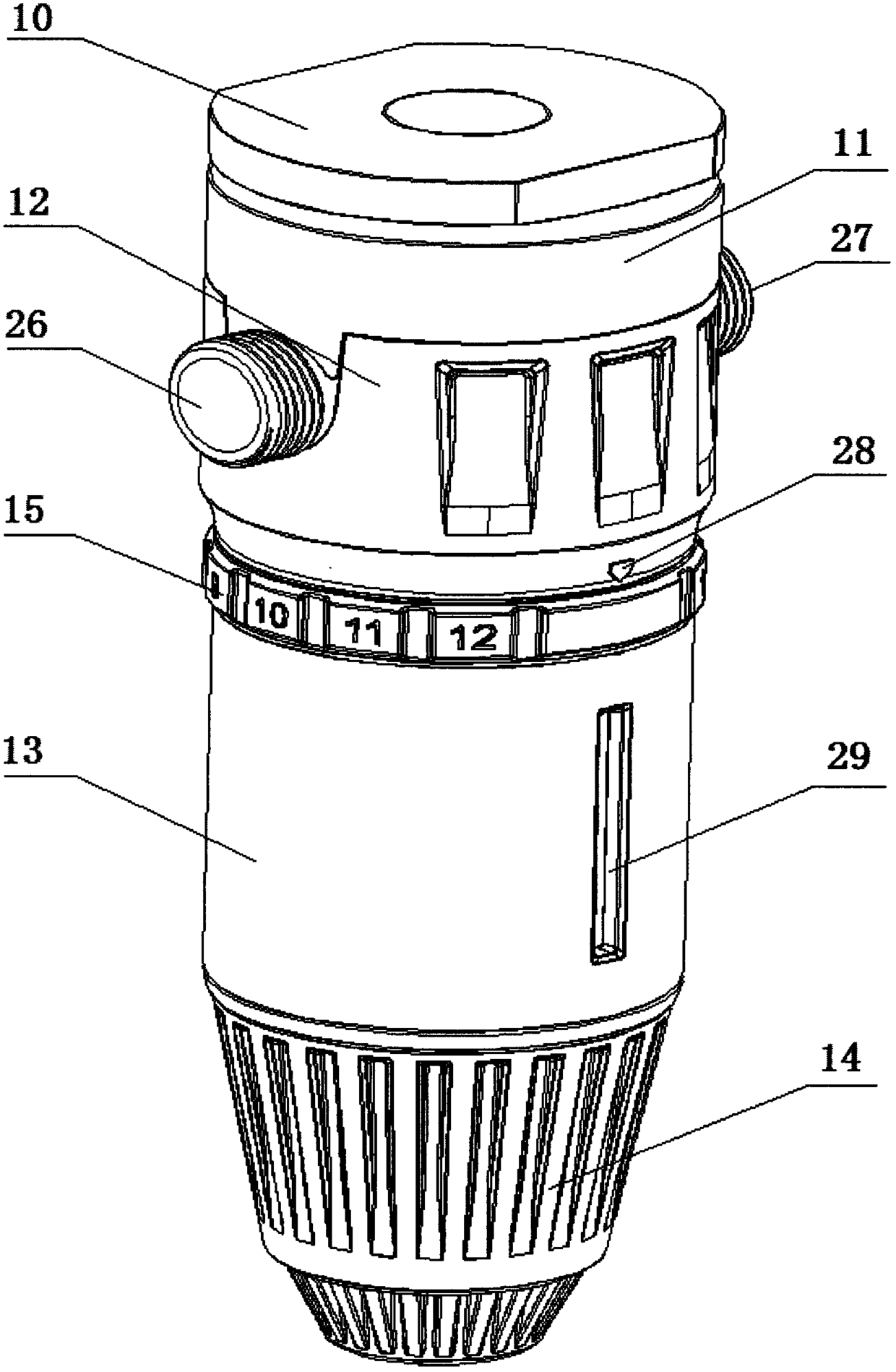

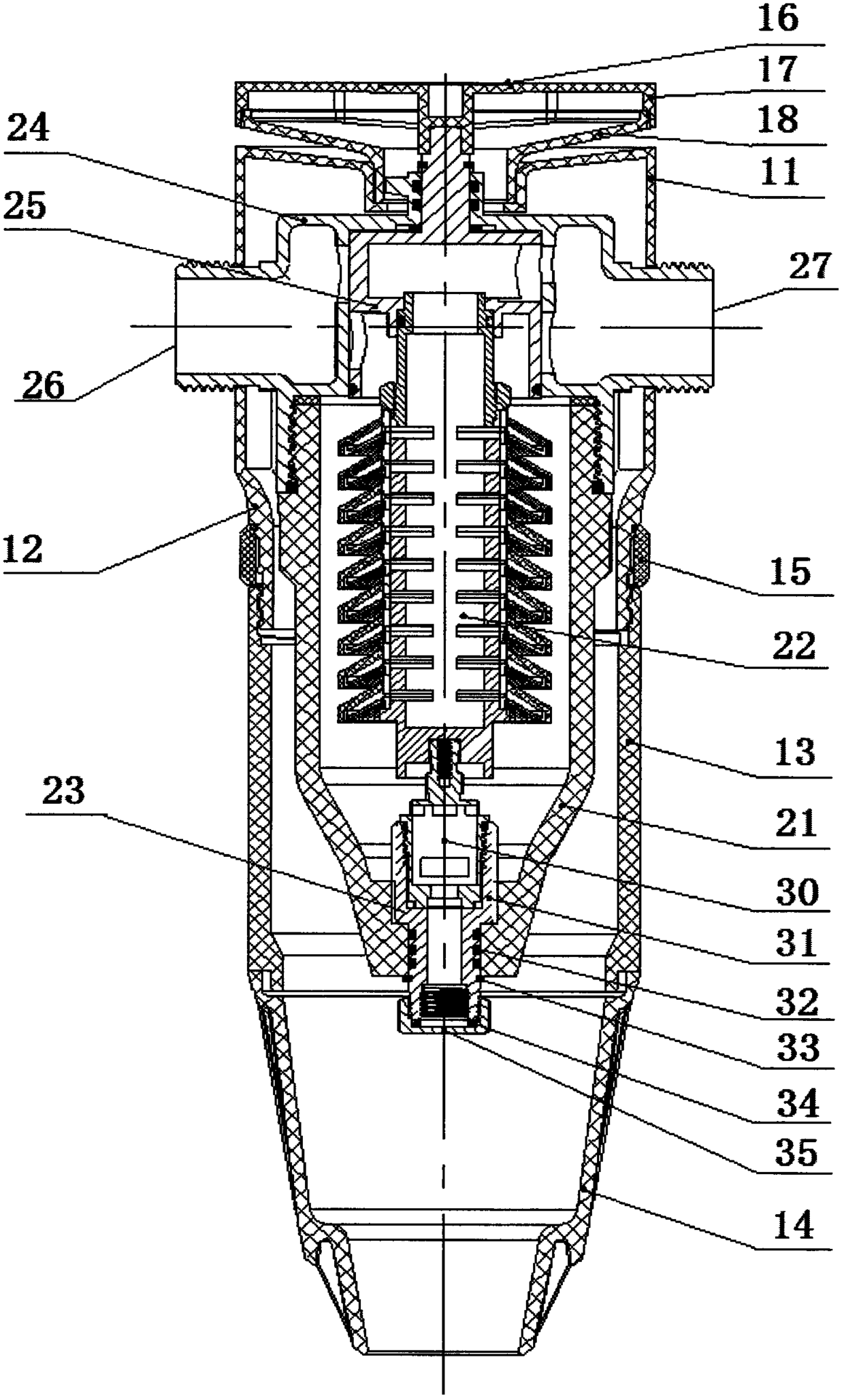

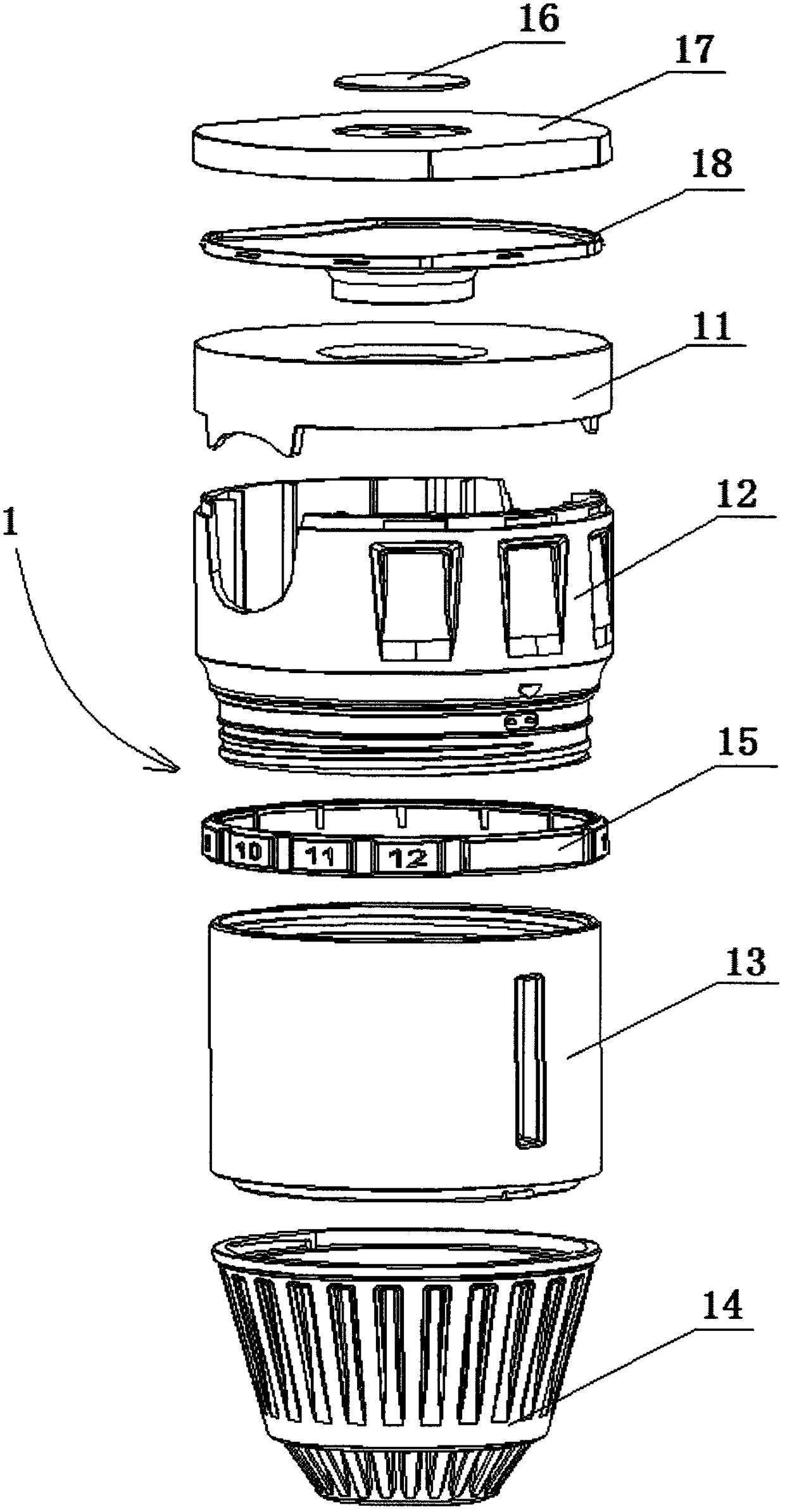

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, a backwash pre-filter includes an outer protective cover 1 and a filter body 2 arranged in the outer protective cover 1. The outer protective cover 1 is sequentially composed of a manual valve handle 10, a plastic protective cover 11, The first plastic sheath 12, the second plastic sheath 13, the outer sewage valve handle 14 and the adjustable decorative ring 15 arranged on the periphery of the lower port of the second plastic sheath 13; the adjustable decorative ring 15 is arranged on the second plastic sheath 13 on the periphery of the lower port and can rotate around its body, the second plastic sheath 13 is provided with a mark 28 on the front, and the outer surface of the adjustable decorative ring 15 is provided with a number representing a recordable cleaning date; the filter body 2 includes a valve body Assembly 20, transparent cup 21, filter ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com