Metal comb of textile tube forward-backward laser cutting mechanism

A cutting mechanism and textile tube technology, applied in the field of metal combs, can solve the problems of inaccurate laser cutting, inability to meet design requirements, unreasonable structural design, etc., and achieve the effect of accurate cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

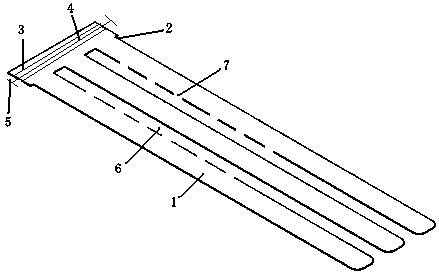

[0009] Combine below figure 1 Specific description embodiment:

[0010] The metal comb of the positive and negative laser cutting mechanism of the textile tube is characterized in that it includes a comb body 1, and the two sides of the head end of the comb body 1 are provided with locking grooves 2, and the head end of the comb body is provided with a concave Groove 3, the spring 4 is arranged in the groove, and the two ends of the spring are connected with the contact plate 5; the tail end of the comb body is opened, and two cutting grooves 6 are opened on the comb body.

[0011] Preferably, several positioning notches 7 are provided on both sides of the cutting groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com