Circular steel tube lifting tool device with telescopic long arms

A technology for round steel pipes and spreaders, applied in the field of spreaders, can solve the problems of waste, excessive time and materials, and low working speed, and achieve the effects of increasing the number of sprays, increasing the speed, and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

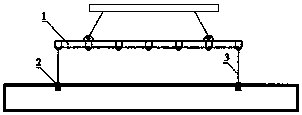

[0009] The present invention will be further explained below in conjunction with the accompanying drawings.

[0010] A telescopic long-arm round steel pipe hanger device, characterized in that it includes a fixed beam, a telescopic mechanism, a round steel, a fixed seat, a limit seat, and a hanger, and is characterized in that: the top of the round steel is connected with a hanging piece, and the round steel The steel is covered with a fixed seat, and the fixed seat is provided with a slip ring.

[0011] The limiting seat is fixedly connected to the bottom of the round steel, and the two ends of the limiting seat are provided with limiting holes, and the limiting holes are sleeved on the hook sheet.

[0012] The gearbox of the telescopic mechanism includes a two-stage deployable gear mechanism; the left and right sides of the hanger are symmetrically provided with working balance arms.

[0013] The above content is only a preferred embodiment of the present invention, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com