Assembled type track

An assembled, runway technology, applied in the directions of roads, roads, pavements, etc., can solve the problems of large climate impact and unenvironmental protection, and achieve the effect of quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

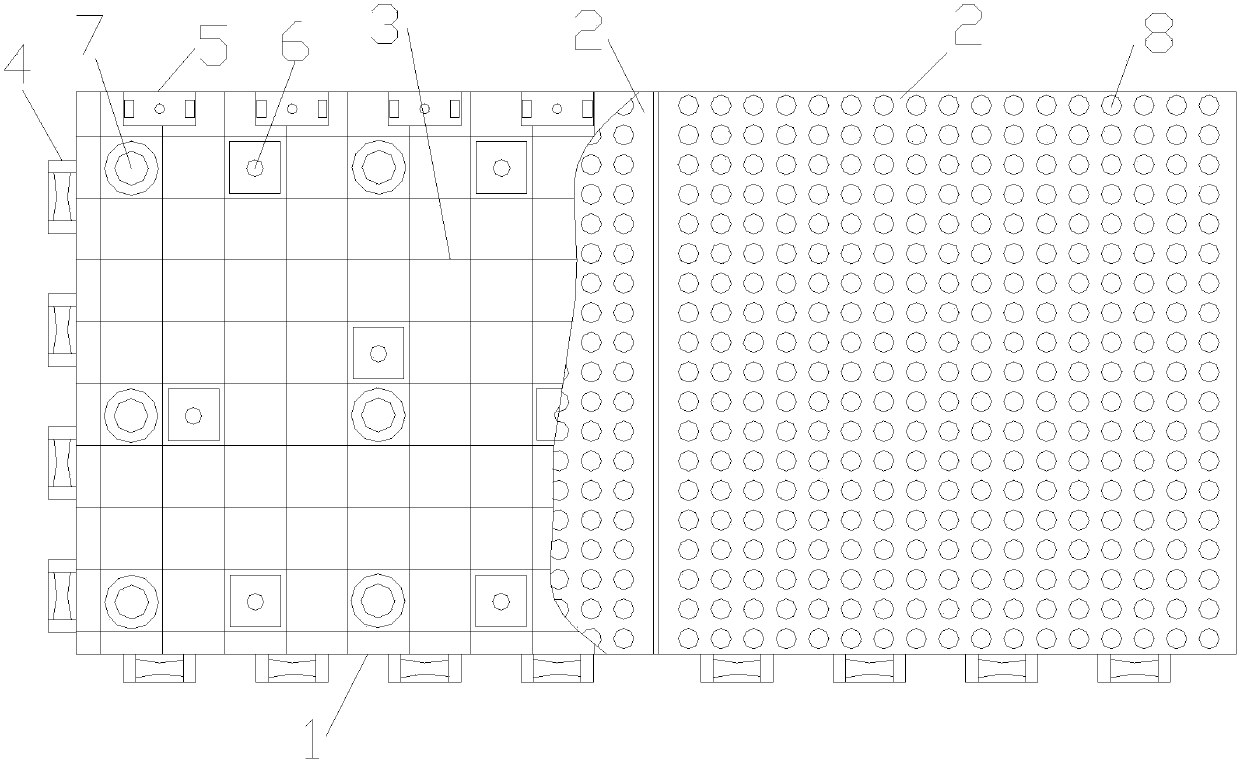

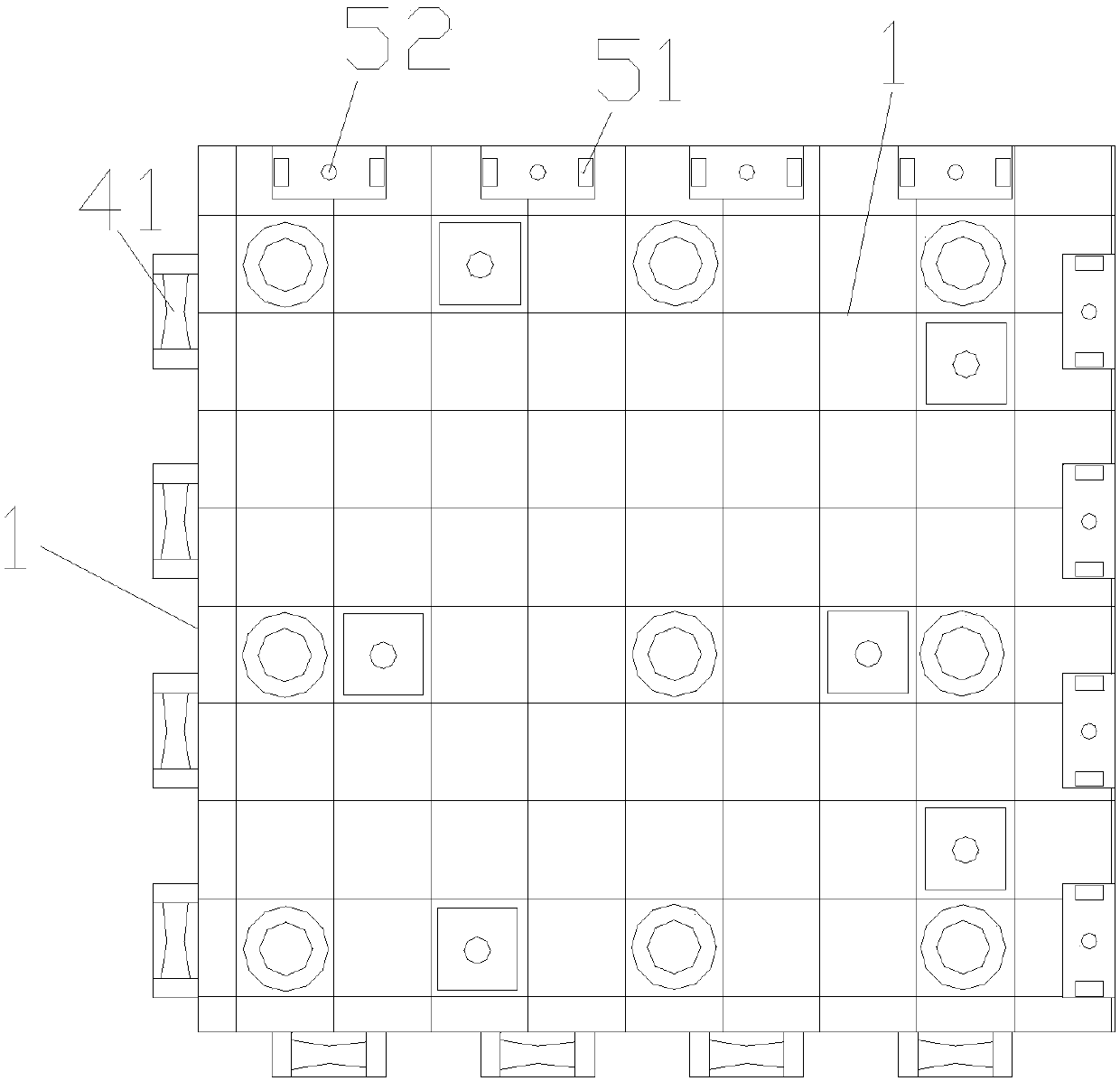

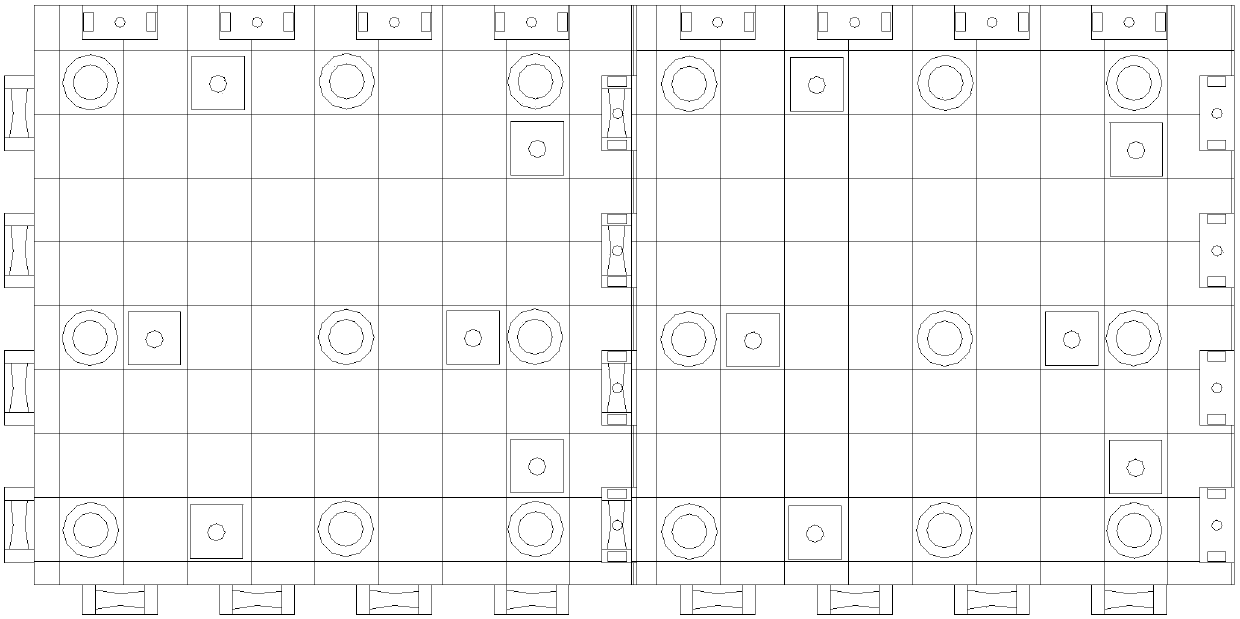

[0015] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, an assembled runway, the main body is formed by connecting several pallets 1 and several panels 2 with each other, each pallet 1 is formed by connecting several reinforcing ribs 3 horizontally and vertically, and the surface of each pallet 1 is provided with a number of expansion bolt holes 6 and several card slots 7, the panel 2 is clamped in the card slot 7 of the corresponding supporting plate 1 through the card column 9 provided at the bottom, and the supporting plate 1 is fixed on the ground through the expansion bolt hole 6 through the expansion bolt, and each supporting plate A number of snap-in blocks 4 are arranged on the side, and a number of snap-in blocks 5 are arranged on the end face of each pad body. A snap-in block 51 is arranged at both ends of the snap-in block 5 and a snap-in column 52 is arranged in the middle, and the snap-in block 4 corresponds to the snap-in block. Corresponding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com