Splicing and water entry floating method for ship lift chamber of ship lift for hydropower station

A technology for ship-bearing compartments and hydropower stations, which is applied in the vertical lifting of ship machinery, ship lifting devices, buildings, etc. It can solve problems such as difficult splicing and installation, difficult lifting and installation, and inability to transport super-large components, so as to improve assembly accuracy and welding quality , to ensure reliable operation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

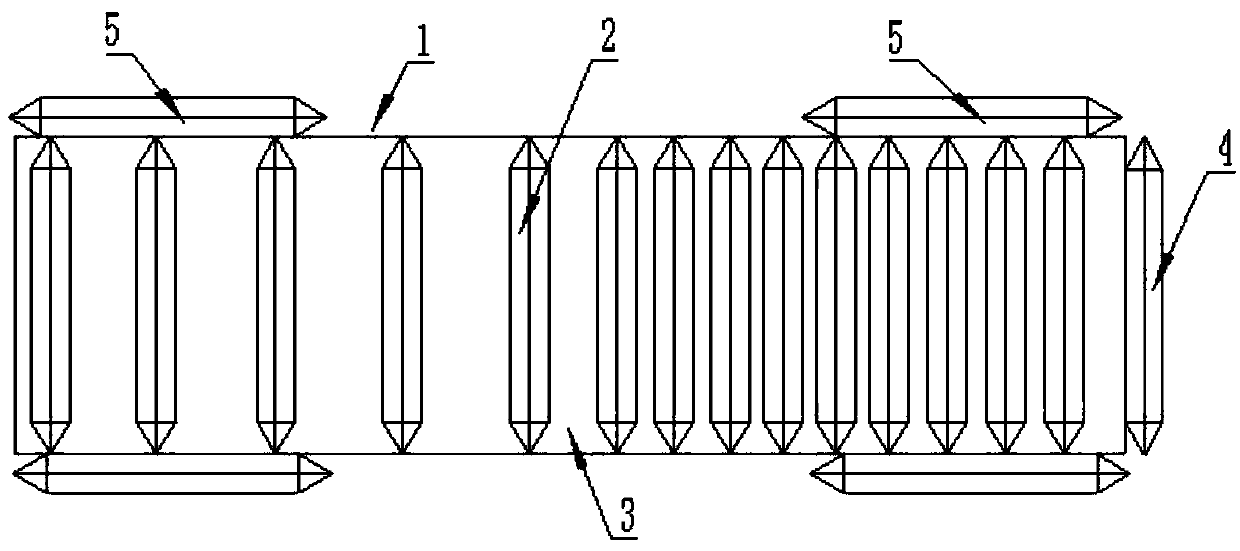

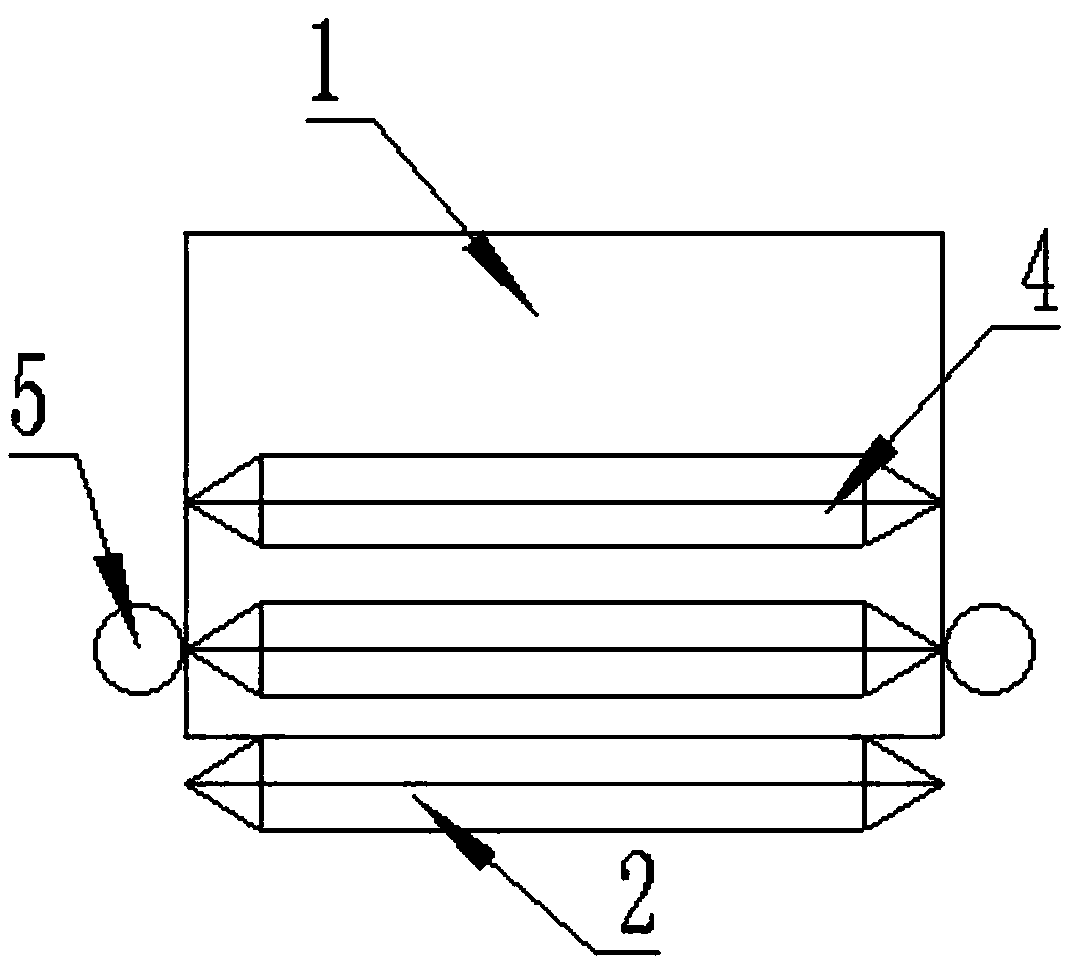

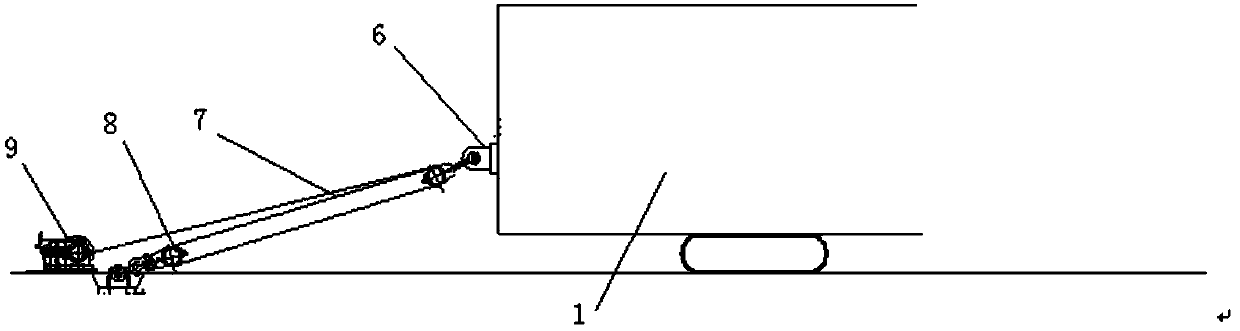

[0022] refer to Figure 1 to Figure 4 According to an embodiment of the present invention, a method for splicing a ship-bearing compartment of a ship lift of a hydropower station into the water for floating transportation comprises the following steps:

[0023] Step 1: Complete the manufacture of each component of the ship-holding compartment 1 at the manufacturer;

[0024] Step 2: Set up an assembly yard for the ship's container 1 in the reservoir area of the hydropower station, and set up an assembly platform whose scale should meet the requirements for the assembly of the ship's container structure, and the launching platform should be close to the waterway, or easily reach the waterway;

[0025] Step 3: Transport the components of the ship-bearing compartme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com