Environment-friendly toilet sewage separating and drying device

A drying device, toilet waste technology, applied in the direction of drying gas arrangement, components of the pumping device for elastic fluid, drying, etc., can solve the problems of troublesome maintenance and replacement of drying fans, and achieve quick disassembly and assembly, saving time and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

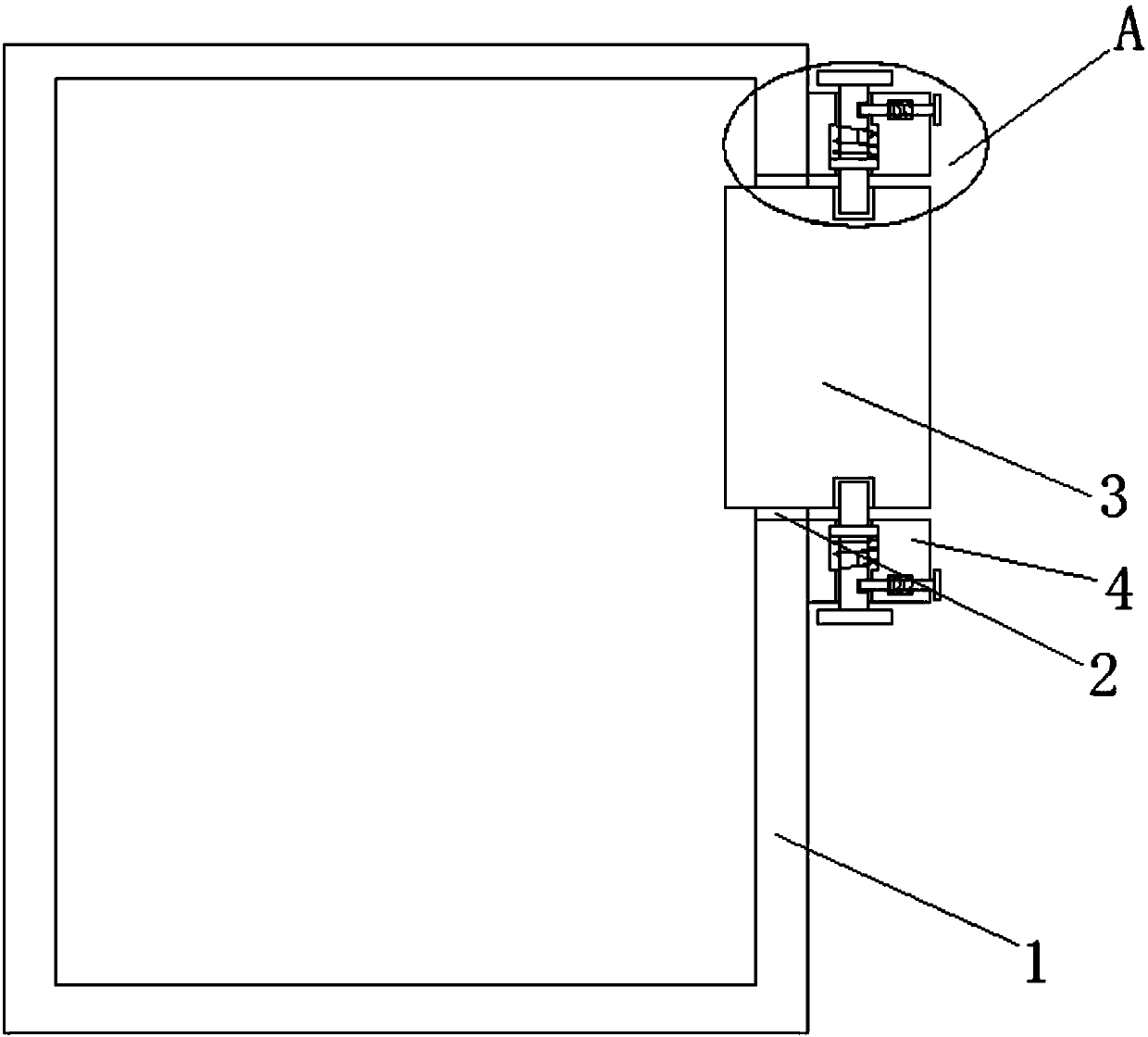

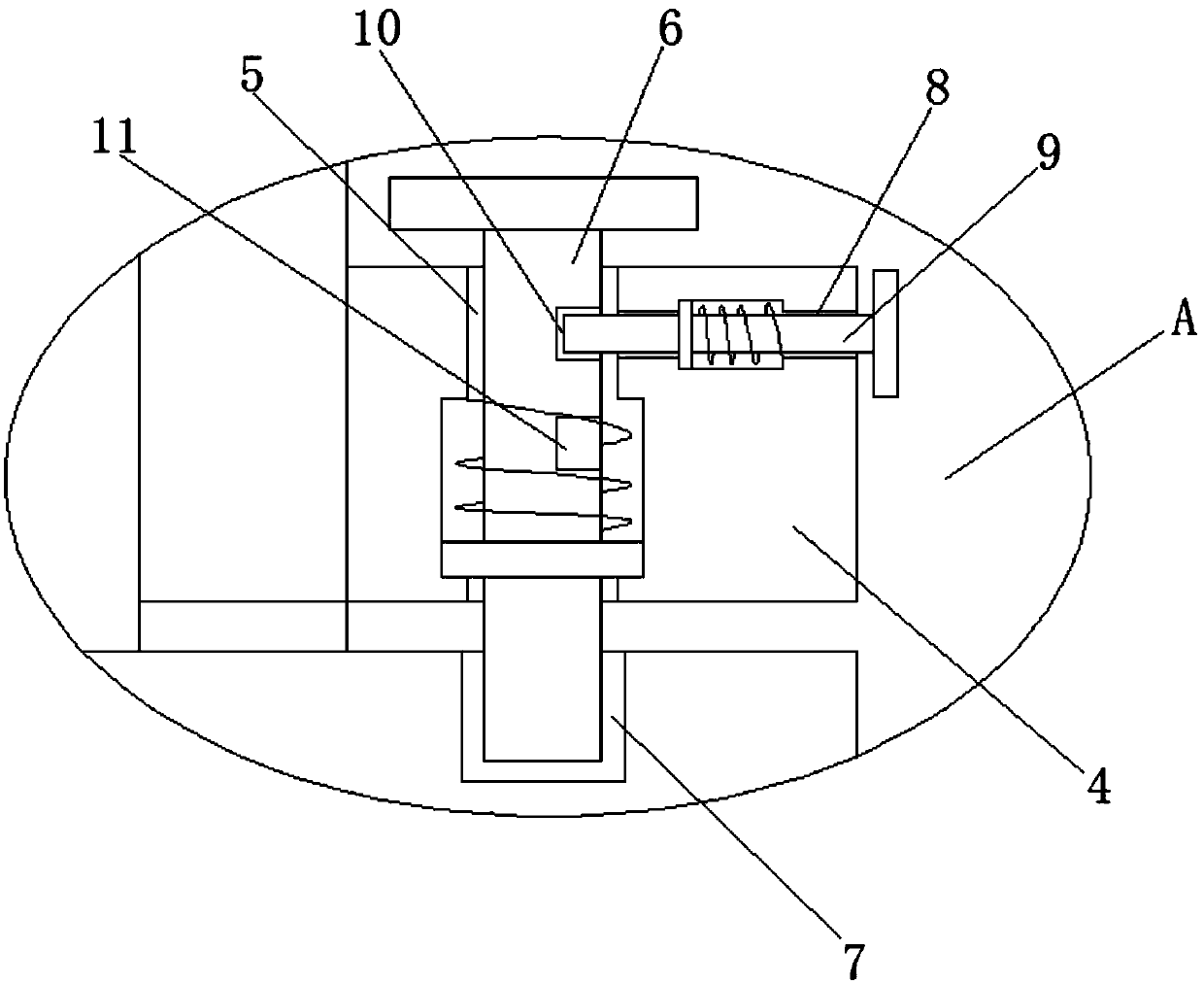

[0015] like Figure 1-Figure 2 As shown, an environmental protection toilet waste separation and drying device mainly includes a device body 1. The device body 1 is a hollow structure. One side of the device body 1 is provided with an installation through hole 2, and a drying fan 3 is slidingly installed in the installation through hole 2. , and both sides of the drying fan 3 extend out of the installation through hole 2, and the side of the device body 1 close to the installation through hole 2 is welded with two fixing blocks 4, and the two fixing blocks 4 are respectively located on both sides of the drying fan 3, The fixed block 4 is provided with a slide bar through hole 5, and a slide bar 6 is slidably installed in the slide bar through hole 5, and both ends of the slide bar 6 extend outside the slide bar through hole 5, and the top side and the bottom side of the drying fan 3 Both are provided with a fixed groove 7, and one end of the slide bar 6 close to the drying fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com