Grinding machine with transition gear bidirectional direction-adjustable gearbox and working method thereof

A technology of transitional gears and gearboxes, which is applied in the direction of belts/chains/gears, gear transmissions, machine tools suitable for grinding workpiece planes, etc. Complex gearbox mechanism and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In order to make the above features and advantages of the present invention, it can be more easily understood, and the following examples are forth, and the accompanying drawings are described in detail, but the present invention is not limited thereto.

[0038]referenceFigure 1 - Figure 16.

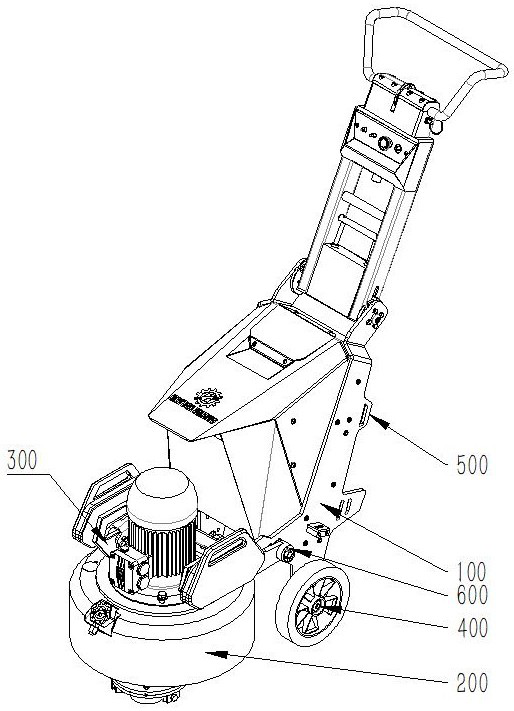

[0039]In a preferred embodiment of the present invention: a grinder with a transition gear two-way movable to the gearbox, including a rack, the front of the frame having a needle to gearbox assembly, the adjustable gear The top of the box assembly is provided with an armrest assembly, and the bottom of the rack is provided with a quick-demolition shaft assembly. The rear of the rack is provided with a suction tube fixing assembly, and the middle of the rack is provided with a quick-removal weight iron assembly. .

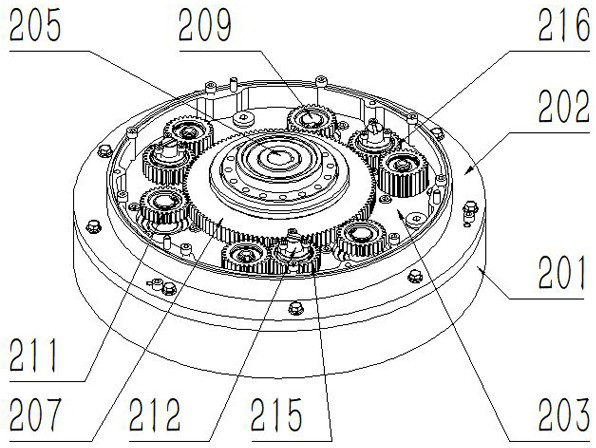

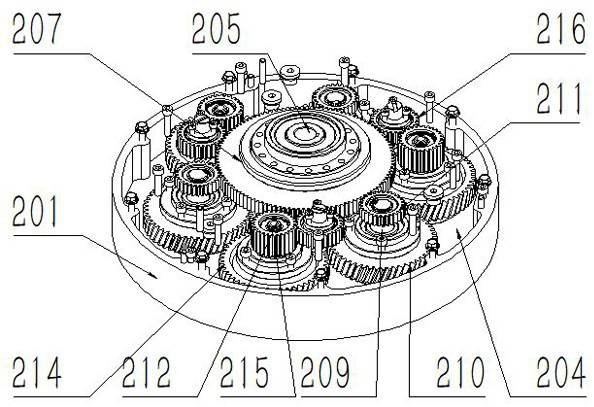

[0040]In the present embodiment, the adjustable gearbox assembly includes a box cover and a casing disposed in a box cover, and the case is separated into a top, lower layer, and a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com