A Structure-Based Refined Simulation Method for High Pressure Feedwater Heater in Nuclear Power Plant

A technology of high-pressure water supply and simulation method, which is applied to water heaters, lighting and heating equipment, preheating, etc., can solve the problem that the accuracy of calculation is difficult to be guaranteed, the parameter distribution of water heaters cannot be reflected, and the generality of simulation models is poor. and other issues to achieve the effect of improving reusability and improving design and development efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following examples describe the present invention in more detail.

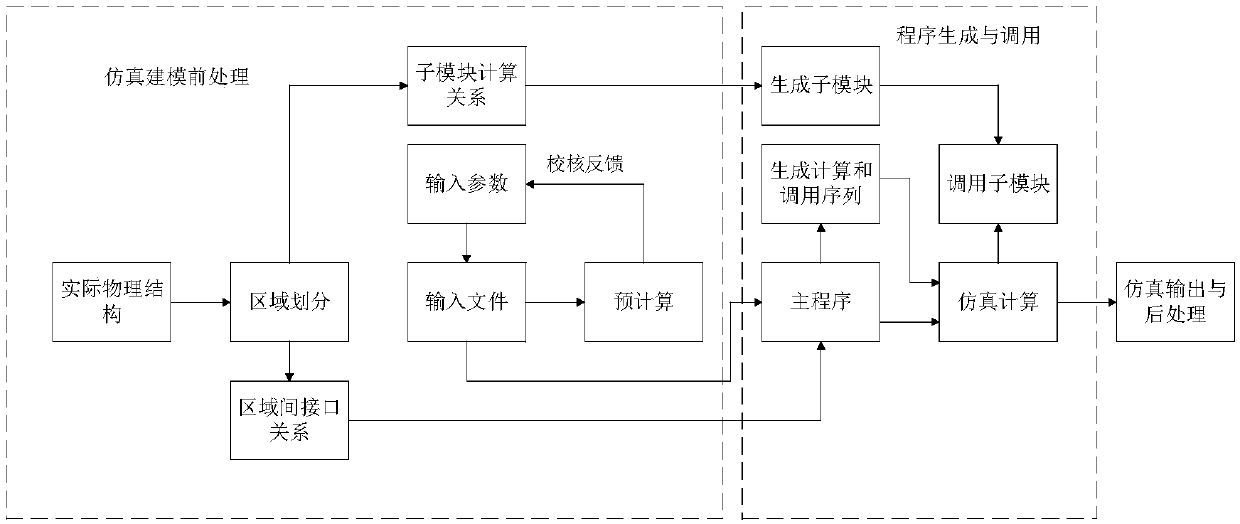

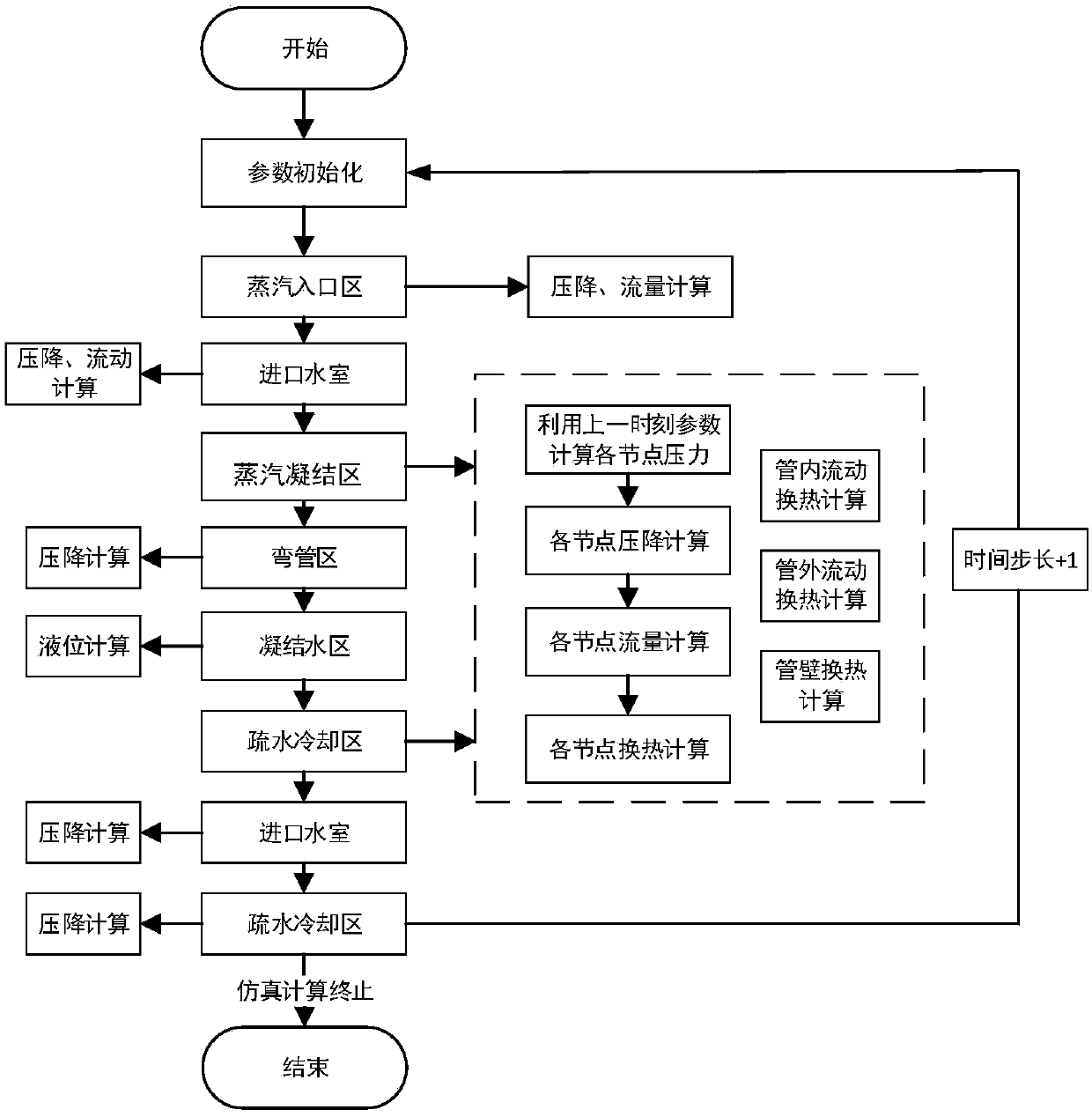

[0032] The structure-based refined simulation method for high-pressure feedwater heaters in nuclear power plants of the present invention specifically includes:

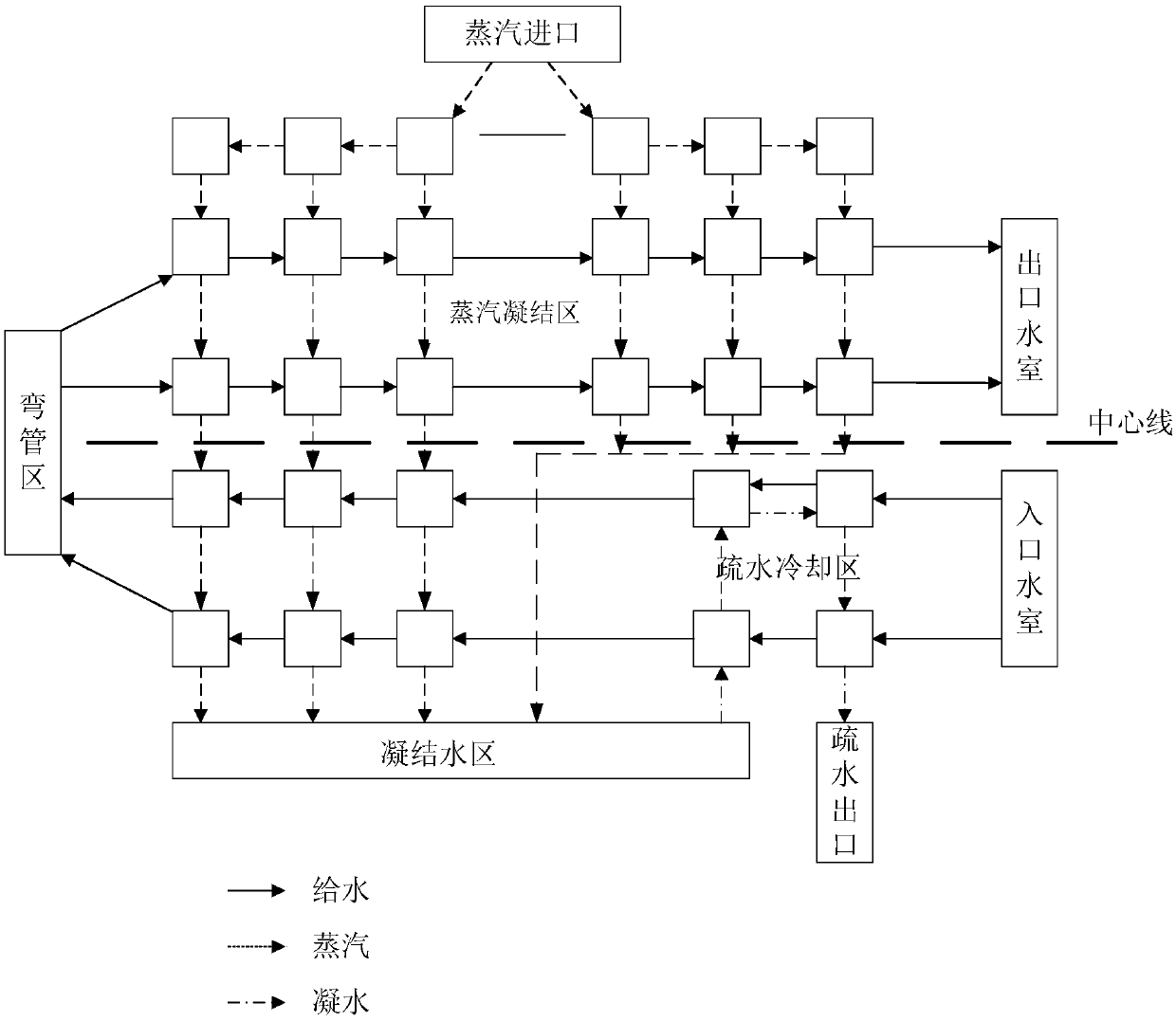

[0033] combine figure 1 , according to the actual physical structure of the high-pressure feedwater heater in the nuclear power plant, during the simulation, it is divided into steam condensation area, drain cooling area, condensation water area, steam inlet area, drain outlet area, inlet water chamber, outlet water chamber, bend administer these areas.

[0034] Such as figure 1 As shown in the area division in , for the steam condensation area and the hydrophobic cooling area, these two areas are divided more carefully according to the actual partitions in the horizontal direction and in accordance with the actual position of the pipe row and the spatial position in the vertical direction. The formed regional blocks correspond to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com