Control method and control device of air flue assembly and equipment

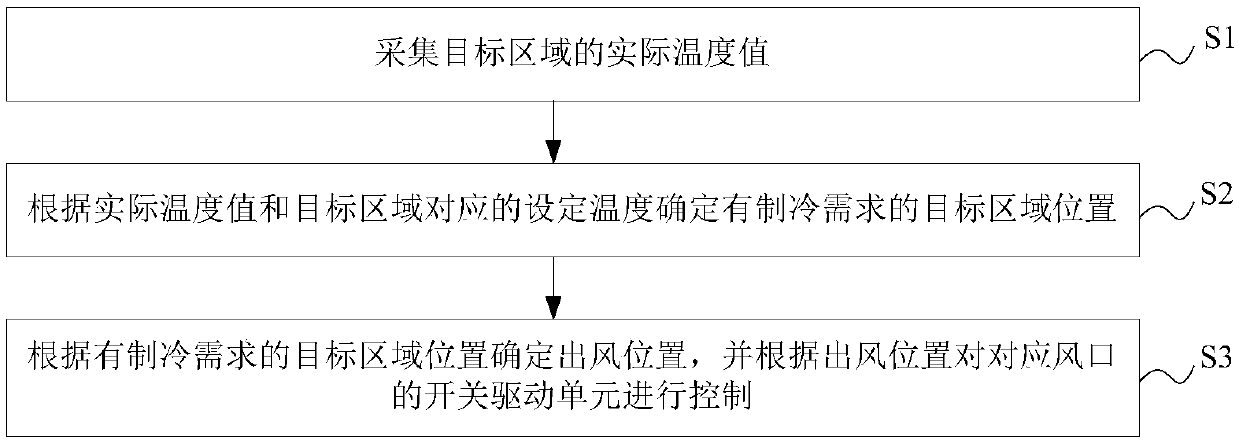

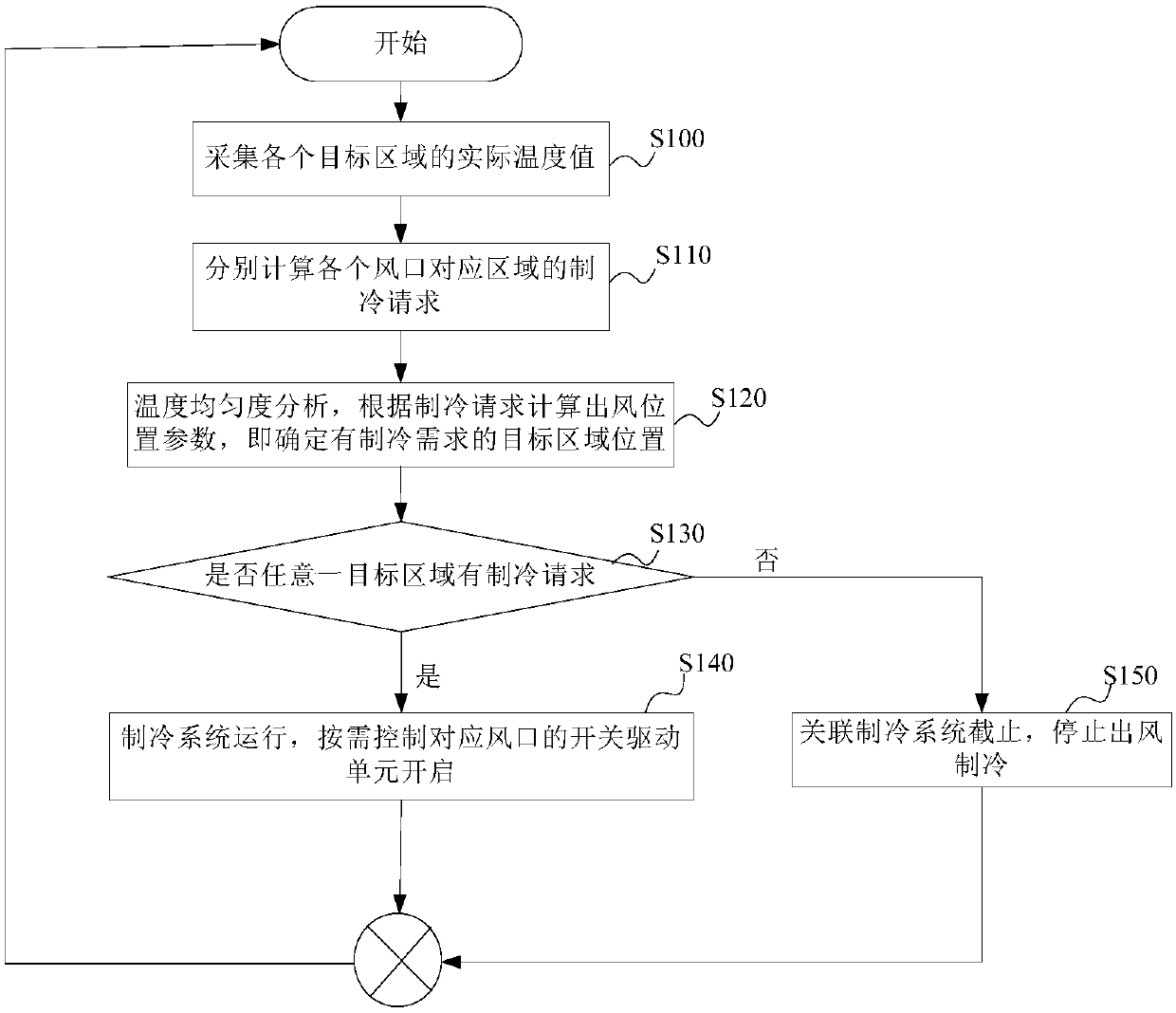

A technology of air duct components and control methods, applied in the field of control of air duct components and control devices of air duct components, capable of solving problems such as poor temperature distribution uniformity in compartments, and achieving the effect of improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1:, and , or 。 example 2:, or , or , or 。 example 3

[0041] In some embodiments of the present invention, the switch driving unit of the tuyeres may be implemented in the following manner, and of course other implementable forms may also be adopted. Example 1: A magnetic switch device is used, and the opening and closing direction movement or the closing direction movement of the tuyere part is realized through the forward and reverse energization of the coil of the magnetic switch device. Example 2: Using a motor drive device, the opening and closing direction movement or closing direction movement of the tuyere components can be realized through the forward or reverse movement of the motor through a rotating device such as a gear or a belt. Example 3: Start the valve or the gas flow control device, and realize the opening and closing direction movement or the closing direction movement of the tuyere component by controlling the opening and closing of the valve.

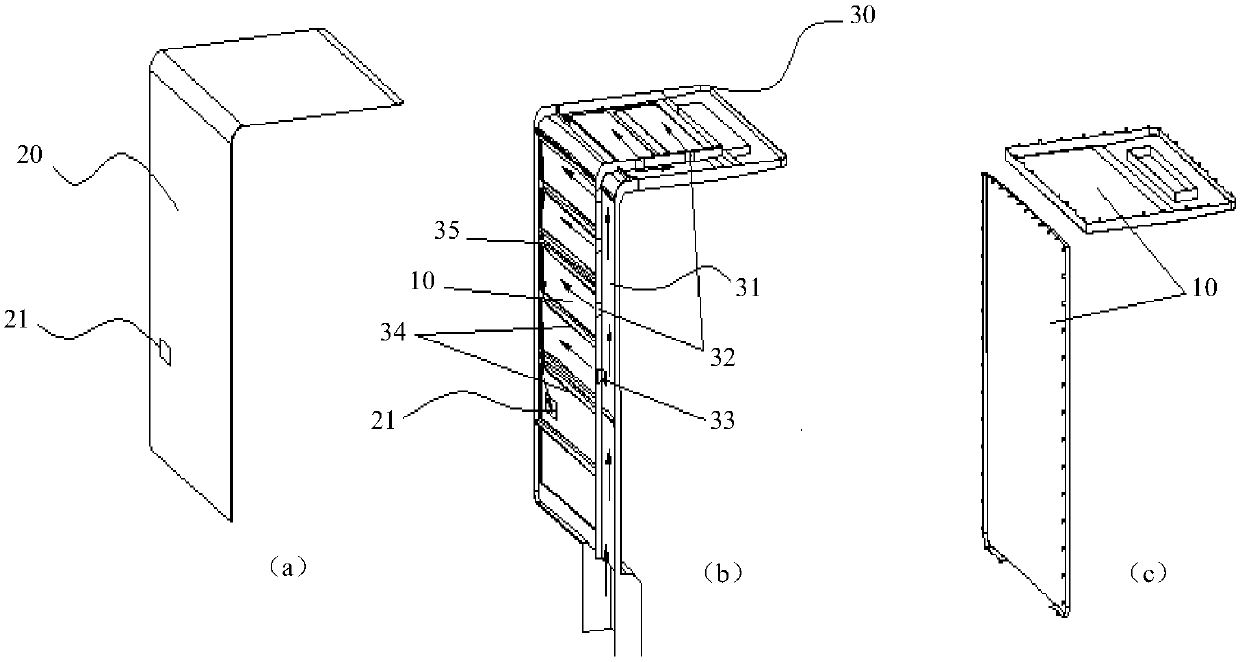

[0042] Based on the structure of the air duct assembly in the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com