lens

A lens and optical axis technology, applied in the direction of lenses, instruments, optics, etc., can solve the problems of poor imaging quality and influence of lenses, achieve the effect of ensuring optical quality and reducing the chance of joint lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

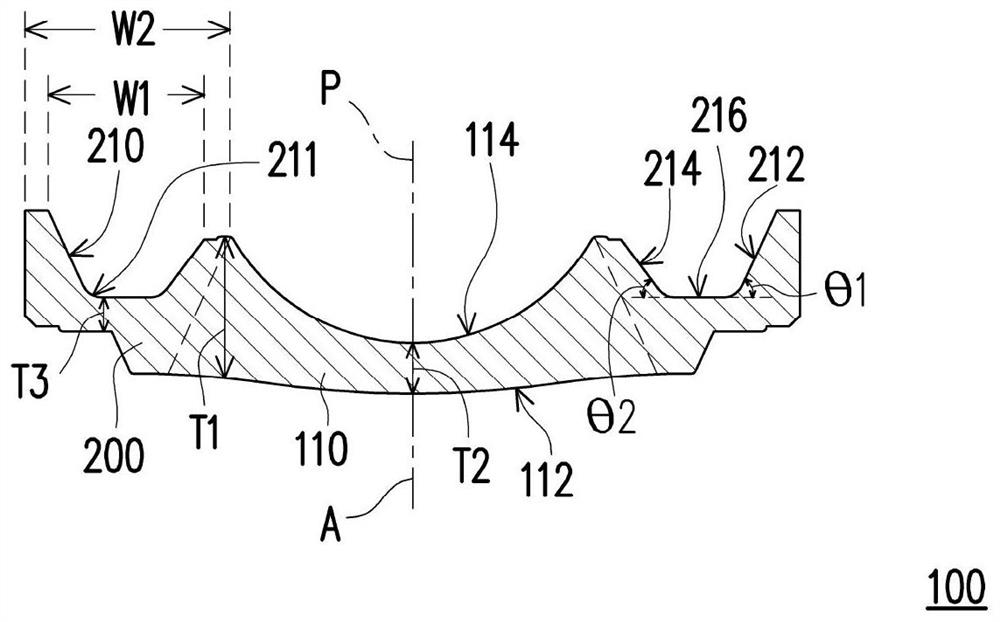

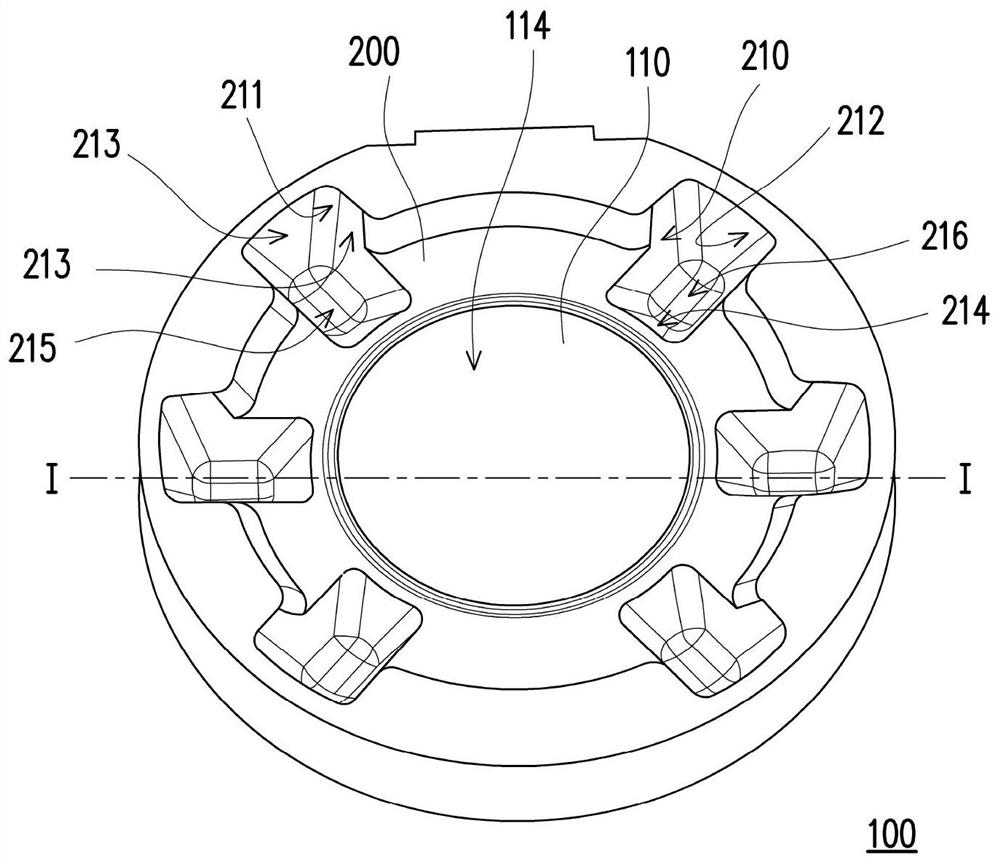

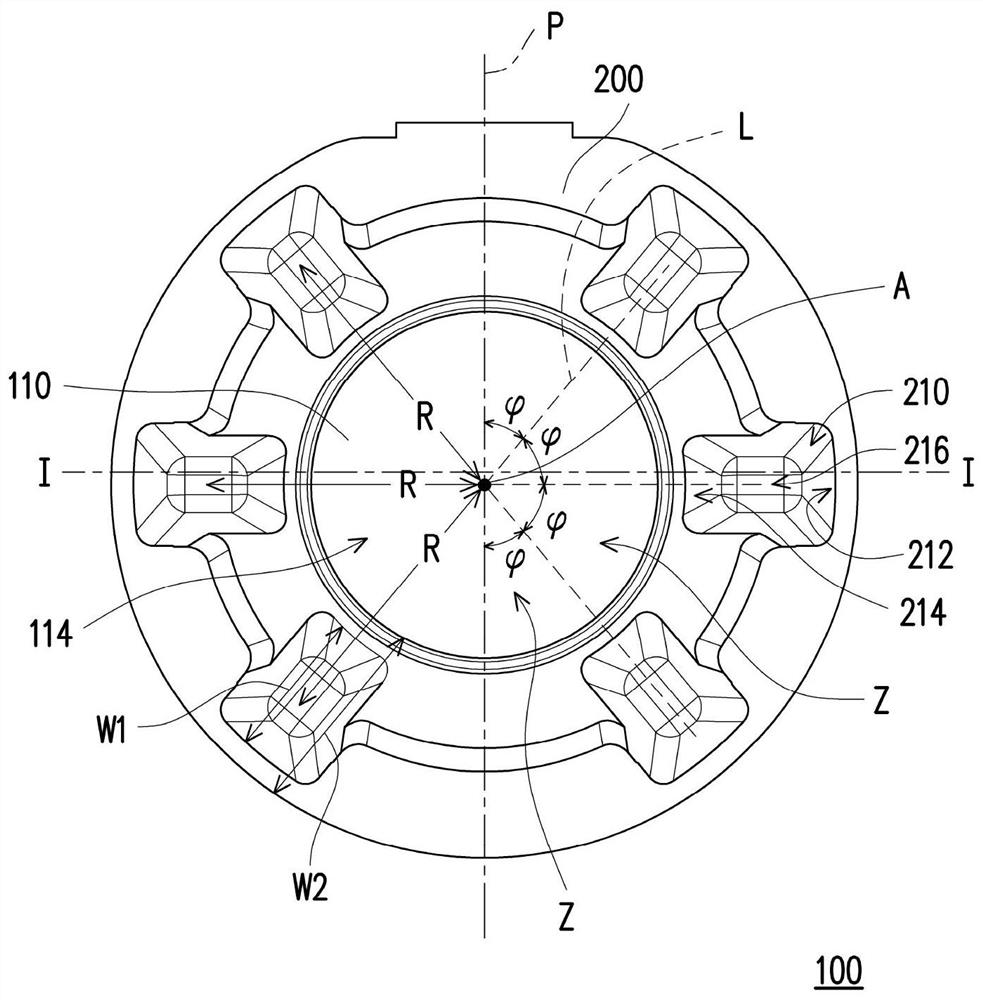

[0050] Figure 1A It is a schematic cross-sectional view of a lens according to an embodiment of the present invention, Figure 1B for Figure 1A The three-dimensional schematic diagram of the lens, and Figure 1C for Figure 1A The schematic diagram of the top view of the lens, where Figure 1A The profile is along the Figure 1B and Figure 1C The profile of the I-I line. Please refer to Figure 1A to Figure 1C , the lens 100 of this embodiment includes a diopter 110 and an edge 200 . The diopter 110 has a negative diopter, so that light rays passing through the diopter 110 are more deflected toward the direction of divergence. The edge portion 200 surrounds the refraction portion 110 and is located outside the effective refraction zone of the lens 100 . The effective refractive area means that when the light passes through this area, it can be effectively focused or astigmatized by the curved surface of the lens 100 (such as the first surface 112 and the second surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com