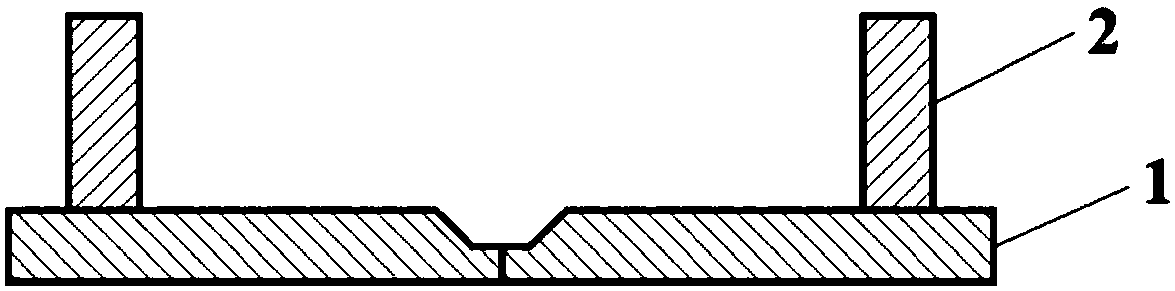

Glass forming mold and forming device and glass forming method

A technology for forming molds and glass, used in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of inability to prepare borosilicate glass with large size and high optical quality, and achieve large size and high optical quality. The effect of improving optical quality and improving optical uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

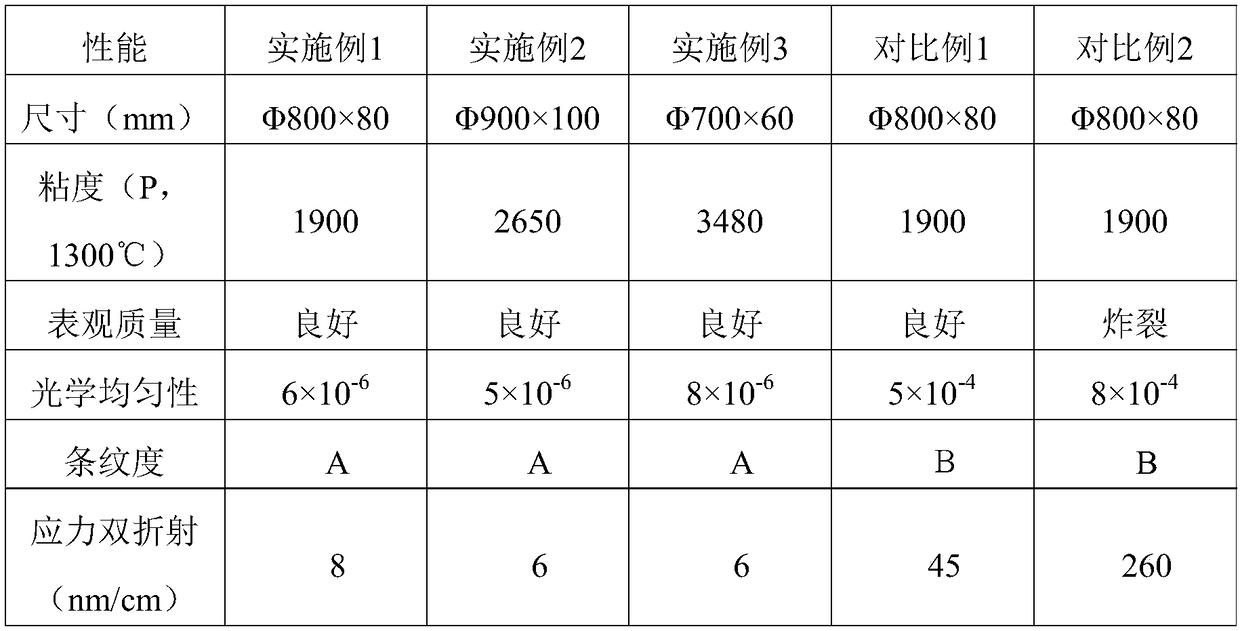

Embodiment 1

[0040] The diameter of the forming die in the forming device used in this embodiment is 800mm; the borosilicate glass that the present embodiment carries out leakage forming is made up of the following components in weight percentage: 68% SiO 2 , 19%B 2 o 3 , 3%Al 2 o 3 , 4.2% Na 2 O, 5%K 2 O, 0.6% ZnO and 0.2% Sb 2 o 3 ;

[0041] The method for forming the above-mentioned borosilicate glass in this embodiment includes the following steps:

[0042] (1) When the glass raw materials of the above components are melted into molten glass and homogenized completely before 3 hours, a layer of boron nitride powder is sprayed on the inner surface of the side mold and the inner surface of the bottom mold of the forming mold, and the water cooling system is turned on. Then heat up the furnace body, the temperature in the furnace body is controlled at 850°C, and the temperature control accuracy is ±1°C;

[0043] (2) After the glass liquid is completely homogenized, the leaking pi...

Embodiment 2

[0048] The diameter of the forming mold in the forming device used in this embodiment is 900 mm; the borosilicate glass that is formed by leakage in this embodiment is composed of the following components in weight percentage: 74.4% SiO 2 , 18%B 2 o 3 , 1% Al 2 o 3 , 1.7% Na2O, 4.2% K 2 O, 0.3% BaO and 0.4% Sb 2 o 3 ;

[0049] The method for forming the above-mentioned borosilicate glass in this embodiment includes the following steps:

[0050] (1) When the glass raw materials of the above components are melted into molten glass and homogenized completely before 5 hours, spray a layer of boron nitride powder on the inner surface of the side mold of the forming mold and the inner surface of the bottom mold, and turn on the water cooling system, Then heat up the furnace body, the temperature in the furnace body is controlled at 820°C, and the temperature control accuracy is ±1°C;

[0051] (2) After the glass liquid is completely homogenized, the leaking pipe is rapidly h...

Embodiment 3

[0056] The diameter of the forming die in the forming device used in this embodiment is 700mm; the borosilicate glass that is formed by leaking material in this embodiment is composed of the following components in percentage by weight: 80% SiO 2 , 12.5% B 2 o 3 , 2.5% Al 2 o 3 , 3.1% Na 2 O, 1%K 2 O, 0.3% BaO and 0.6% Sb 2 o 3 ;

[0057] The method for forming the above-mentioned borosilicate glass in this embodiment includes the following steps:

[0058] (1) When the glass raw materials of the above components are melted into molten glass and homogenized completely before 6 hours, spray a layer of boron nitride powder on the inner surface of the side mold of the forming mold and the inner surface of the bottom mold, and turn on the water cooling system, Then heat up the furnace body, the temperature in the furnace body is controlled at 1000°C, and the temperature control accuracy is ±1°C;

[0059] (2) After the glass liquid is completely homogenized, the leaking p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com