A molding die and molding process for a continuous fiber reinforced ceramic filter element

A technology for molding molds and continuous fibers, which is applied in the field of molding molds and molding techniques for ceramic filter elements, can solve problems such as difficulty in suction filtration and cleaning, uneven suction filtration, and difficulty in demoulding, and achieve low manufacturing costs, easy molding, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

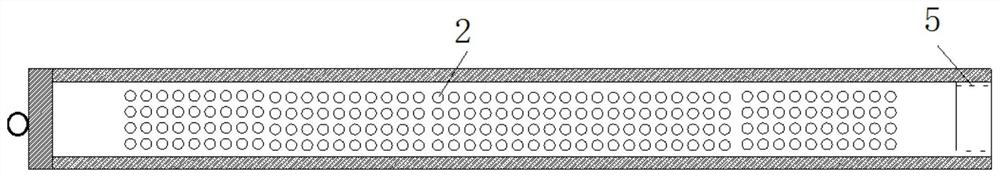

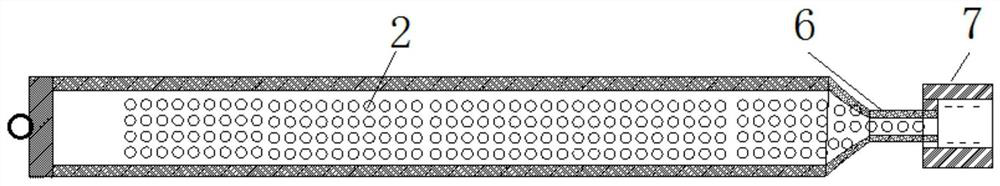

[0040] This embodiment provides a porous mold for ceramic winding molding, that is, a molding mold 1 for a continuous fiber-reinforced ceramic filter element. It includes a pipe body with a diameter of 30-120mm and a length of 1500-3000mm. The pipe body is provided with a plurality of perforations 2 evenly distributed on the main body of the pipe body. The diameter of the perforations 2 is 2-3mm. The spacing is 5-10mm, and the material of the pipe body is preferably metal. If the diameter of perforation 2 is less than 2mm, it is easy to be blocked by slurry during the molding process, and suction filtration and cleaning are difficult. If the diameter is larger than 3mm, it will cause uneven suction filtration and even difficulty in demoulding. The forming mold has a taper of not less than 2% along the length direction and the demoulding direction, otherwise, if the taper is too small, it will cause difficulty in demoulding due to the low strength of the dried green body.

[0...

Embodiment 2

[0050] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0051] Design and process a porous forming mold with a diameter of 40mm and an effective length of 1500mm according to the above-mentioned embodiment, fix the closed end of the mold on the rotary chuck of the winding equipment, and connect the other end with the vacuum system through a rotary joint. When winding, the continuous fiber passes through the short fiber slurry containing carboxymethyl cellulose and polyvinyl alcohol, and is wound along the mold at a certain angle. In the winding process, the initial vacuum degree is controlled at 0.02MPa. As the winding progresses, the vacuum degree gradually increases to 0.06MPa. When the thickness of the green body reaches 10mm, stop winding, remove the vacuum system, take out the forming mold, and put it into the drying kiln Drying and demoul...

Embodiment 3

[0054] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0055] Design and process a porous forming mold with a diameter of 60mm and an effective length of 1600mm according to the above-mentioned embodiment, fix the closed end of the mold on the rotary chuck of the winding equipment, and connect the other end with the vacuum system through a rotary joint. When winding, the continuous fiber passes through the short fiber slurry containing carboxymethyl cellulose and polyvinyl alcohol (amount of 1:2), and is wound along the mold at a certain angle. In the winding process, the initial vacuum degree is controlled at 0.02MPa. As the winding progresses, the vacuum degree gradually increases to 0.05MPa. When the thickness of the green body reaches 11mm, stop winding, remove the vacuum system, take out the forming mold, and put it into the drying kiln D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com