Ultra-thin electromechanical energy storage devices

An energy storage device, electrochemical technology, applied in the field of electrochemical systems, can solve problems such as multi-space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

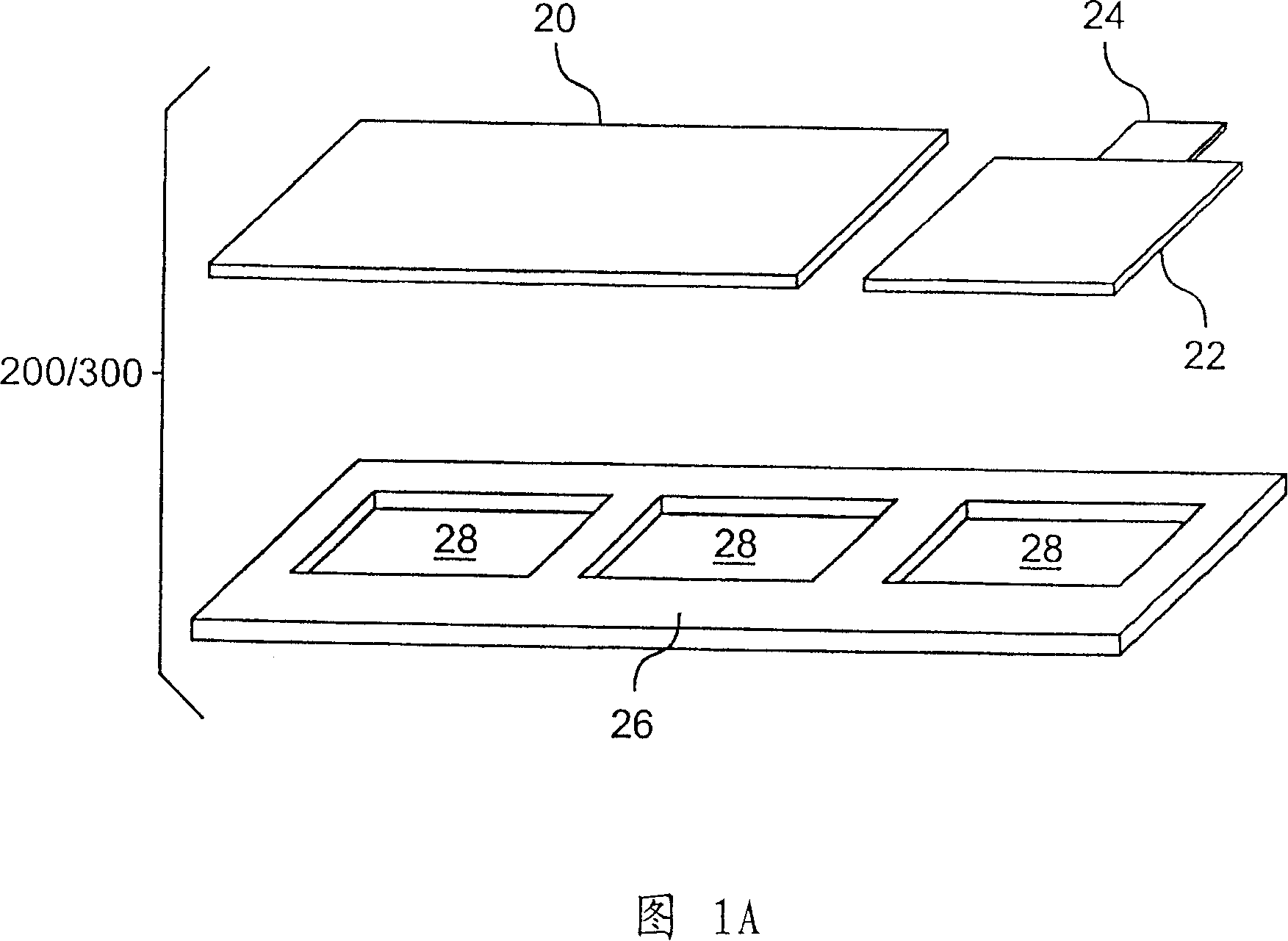

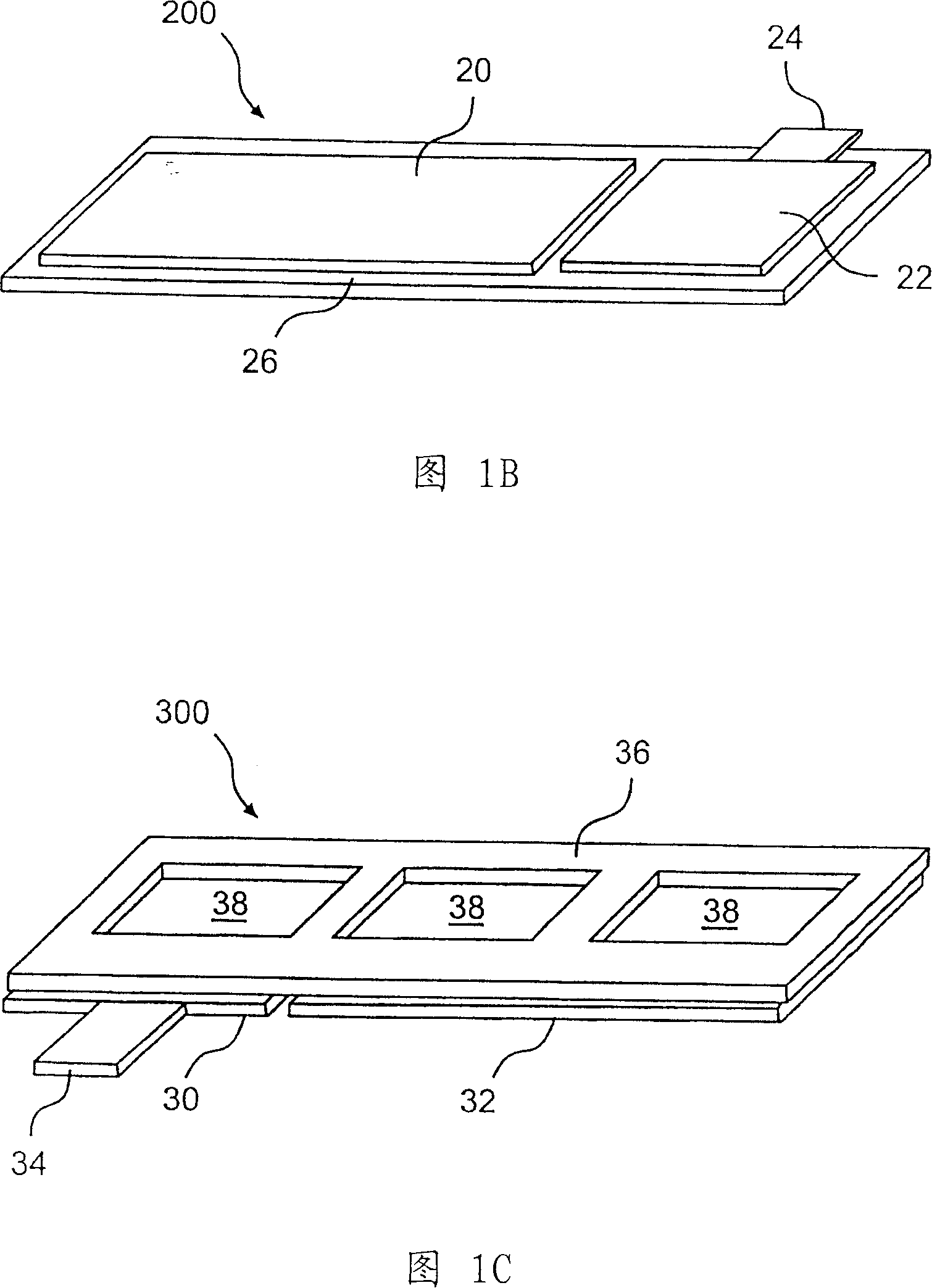

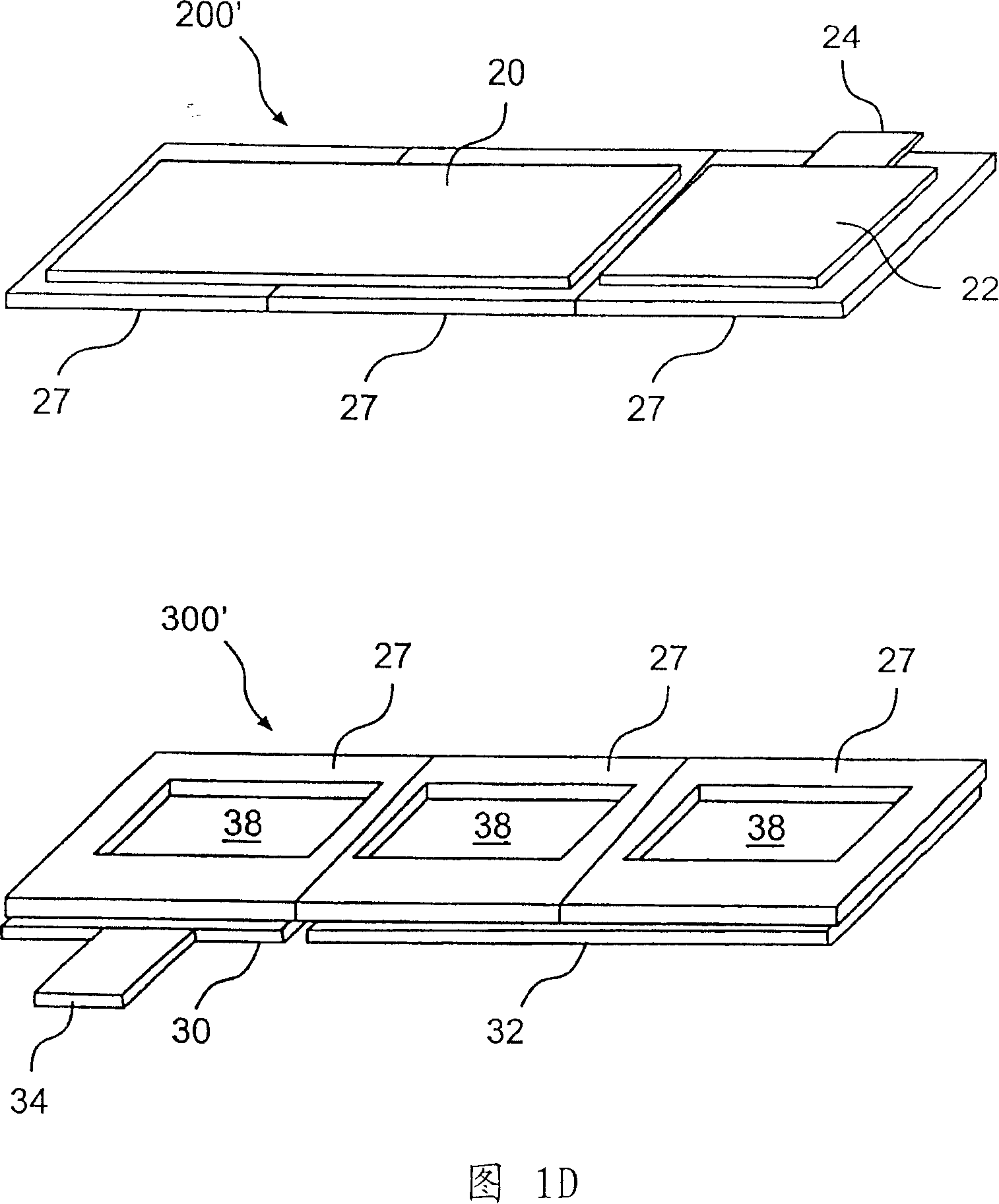

[0066] The double-layer capacitor energy storage device consists of six cells. The structure is shown in Figure 1-5. The batteries are connected into three battery packs connected in series. Each battery pack consists of two bipolar connected cells. Each cell consists of: an anode and cathode, a proton-conducting polymer membrane between the electrodes, a single-layer carbon / plastic composite conductive film, and common and terminal current collectors. The anode and cathode consist of high surface area carbon powder and an aqueous solution of sulfonic acid. The current collectors include a first layer of conductive carbon composite thin film and a second outer metal layer, the first layer being in contact with the outer electrodes of each battery pack. The dimensions of the part are 54 x 34 x 0.5mm.

example 2

[0068] The double-layer capacitor energy storage device consists of six cells. The structure is shown in Figure 1-5. The batteries are connected into three battery packs connected in series. Each battery pack includes two bipolar connected cells. Each cell consists of: an anode and cathode, a proton-conducting polymer membrane between the electrodes, a single-layer carbon / plastic composite conductive film, and common and terminal current collectors. The anode and cathode consist of high surface area carbon powder and an aqueous solution of sulfonic acid. The current collectors include a first layer of conductive carbon composite thin film and a second outer metal layer, the first layer being in contact with the outer electrodes of each battery pack. The dimensions of the part are 54 x 25 x 0.5 mm.

example 3

[0070] The double-layer capacitor energy storage device consists of six cells. The structure is shown in Figure 1-5. The cells are connected into two battery packs connected in series. Each battery pack consists of three bipolar connected cells. Each cell consists of: an anode and cathode, a proton-conducting polymer membrane between the electrodes, a single-layer carbon / plastic composite conductive film, and common and terminal current collectors. The anode and cathode consist of high surface area carbon powder and an aqueous solution of sulfonic acid. The current collectors include a first layer of conductive carbon composite film and a second outer metal layer, the first layer being in contact with the outer electrodes of each battery pack. The dimensions of this part are 34×34×0.8mm.

[0071] Figure 10 provides a comparison table of several materials that can be used in a double layer common or terminal current collector with respect to their lateral conductivity and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com