Optical lens, lens barrel and air cooling structure

A technology of optical mirrors and lens barrels, applied in the field of optical systems, can solve problems such as complex design, low efficiency, and high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

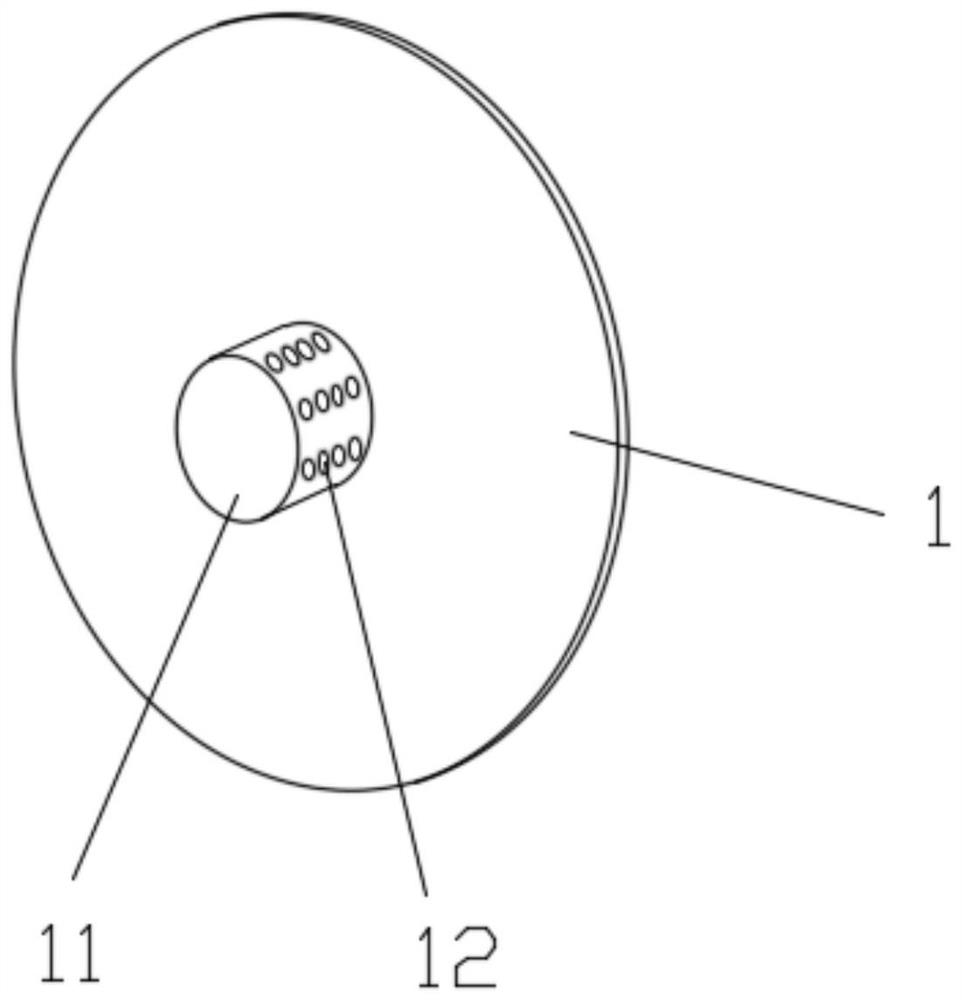

[0041] In this embodiment, the diameter of the optical mirror body 1 is 1m, and the heat of the optical mirror body 1 after absorbing the heat of the laser is 50 W / ㎡; the length of the lens barrel 2 is 1.5 m; the gas in the lens barrel 2 is air, and the ambient pressure is not less than 1 atm .

[0042] The axial distribution range of the second air holes 21 on the wall of the lens barrel 2 is 0.1m, the diameter of the second air holes 21 is 0.01m, and there are 10 rows evenly distributed on the circumference, 4-5 in each row, and the hole distance of each row is 0.02m . The diameter of the first ventilation holes 12 is 0.01m, the hole pitch is 0.02m, and the axial distribution range is 0.1m.

[0043] When working, the intake gas is pure nitrogen, and the intake velocity V 进气 =0.1m / s, pumping speed V 抽气 =V 进气 .

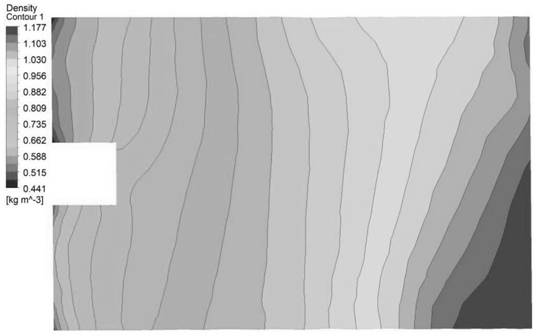

[0044] Such as Figure 5 As shown, the density in the lens barrel 2 of the prior art is distributed in the range of 0.441-1.177 kg / m³, and the gas density near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com