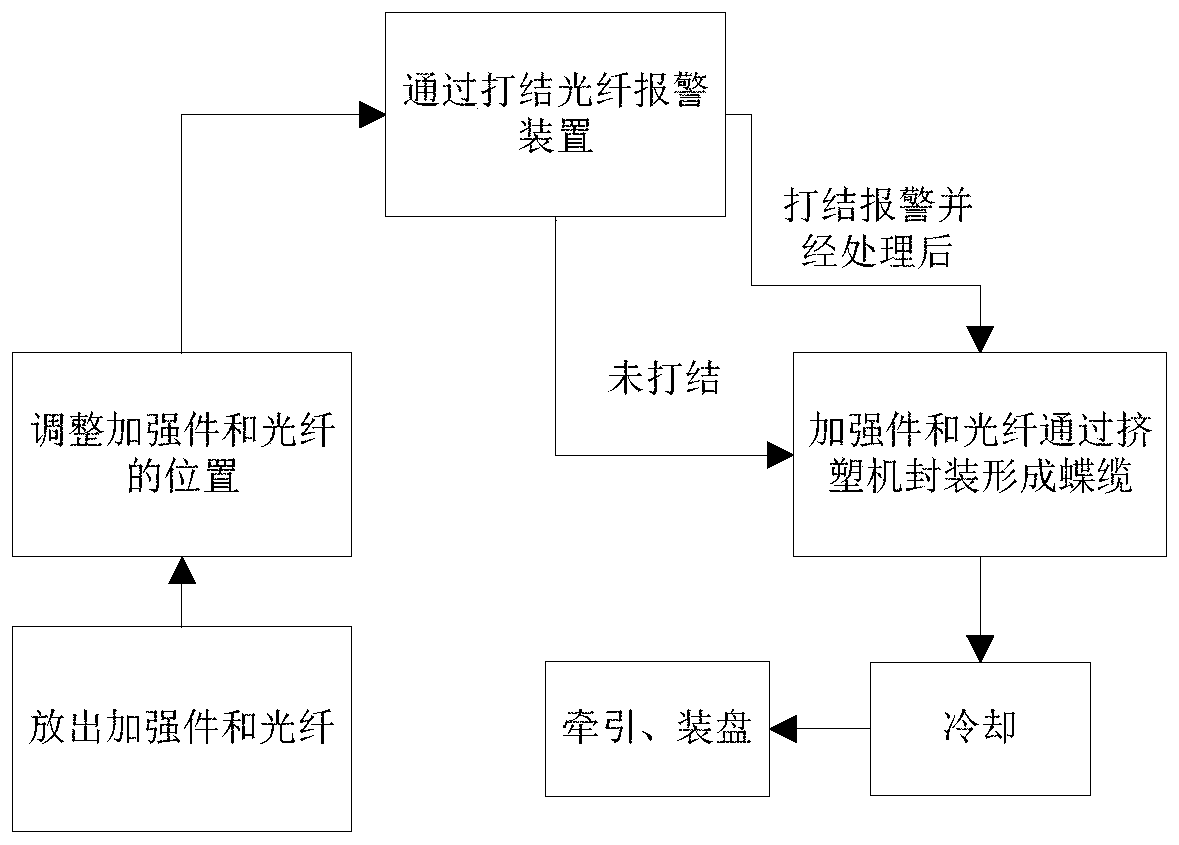

Butterfly cable production process

A production process and butterfly cable technology, applied in the field of butterfly cable production technology, can solve the problems of broken fiber resources, waste efficiency, reduction, etc., and achieve the effect of improving production efficiency, avoiding fiber breaking, and reducing waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

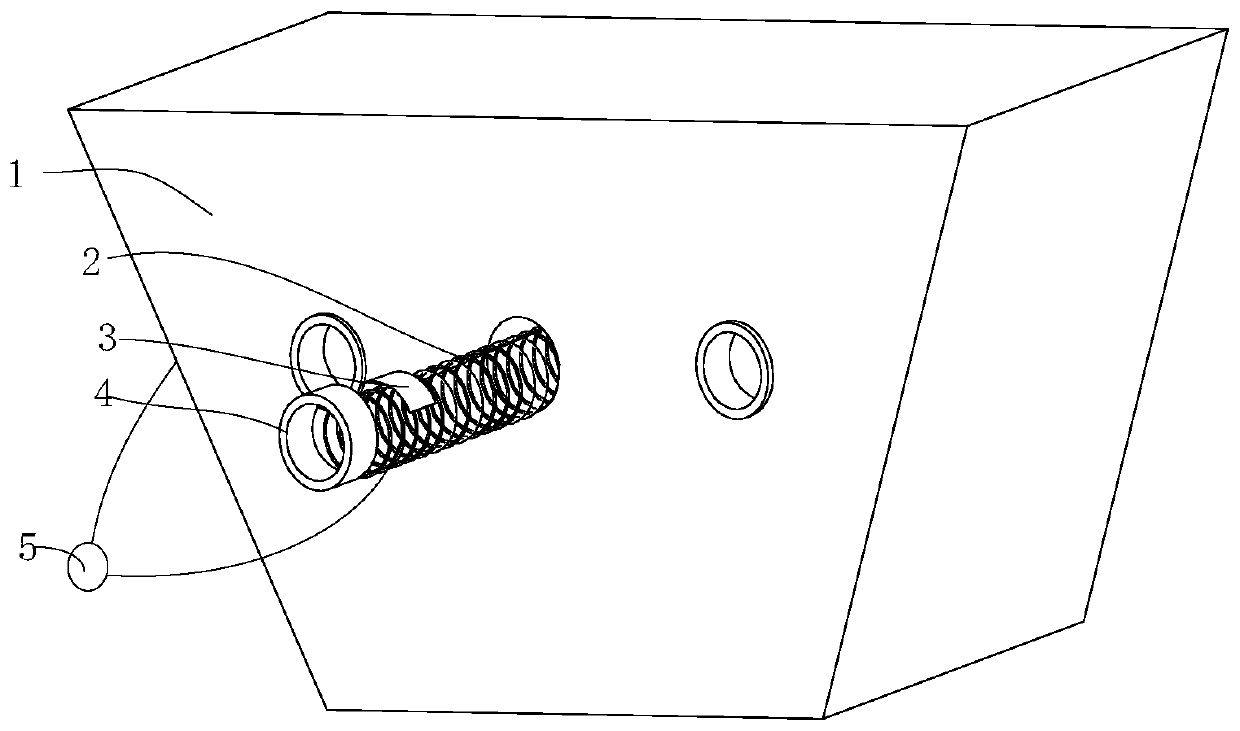

[0023] The invention provides a production process of a butterfly cable. In the production process of the butterfly cable, the optical fiber is transmitted into the extrusion machine in the production line to process the sheath through transmission. During the transmission process, the optical fiber is always in a straight state, and there is a certain tension between the optical fibers. If the optical fiber is knotted, Thin optical fibers are prone to breakage under tension. In the present invention, the transmitted optical fiber passes through the plate body that only straight optical fiber passes through, and a spring is arranged in the plate body, and a pressure sensor is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com