Optical module and method of producing optical module

An optical module and manufacturing method technology, applied in the coupling of optics, optical components, optical waveguides, etc., can solve problems such as operability, impact resistance, mechanical reliability, fiber breakage, etc., to avoid fiber breakage and simplify Manufacturing process, the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The first embodiment will be described.

[0039] First, the optical module 1 according to the first embodiment of the present invention will be described.

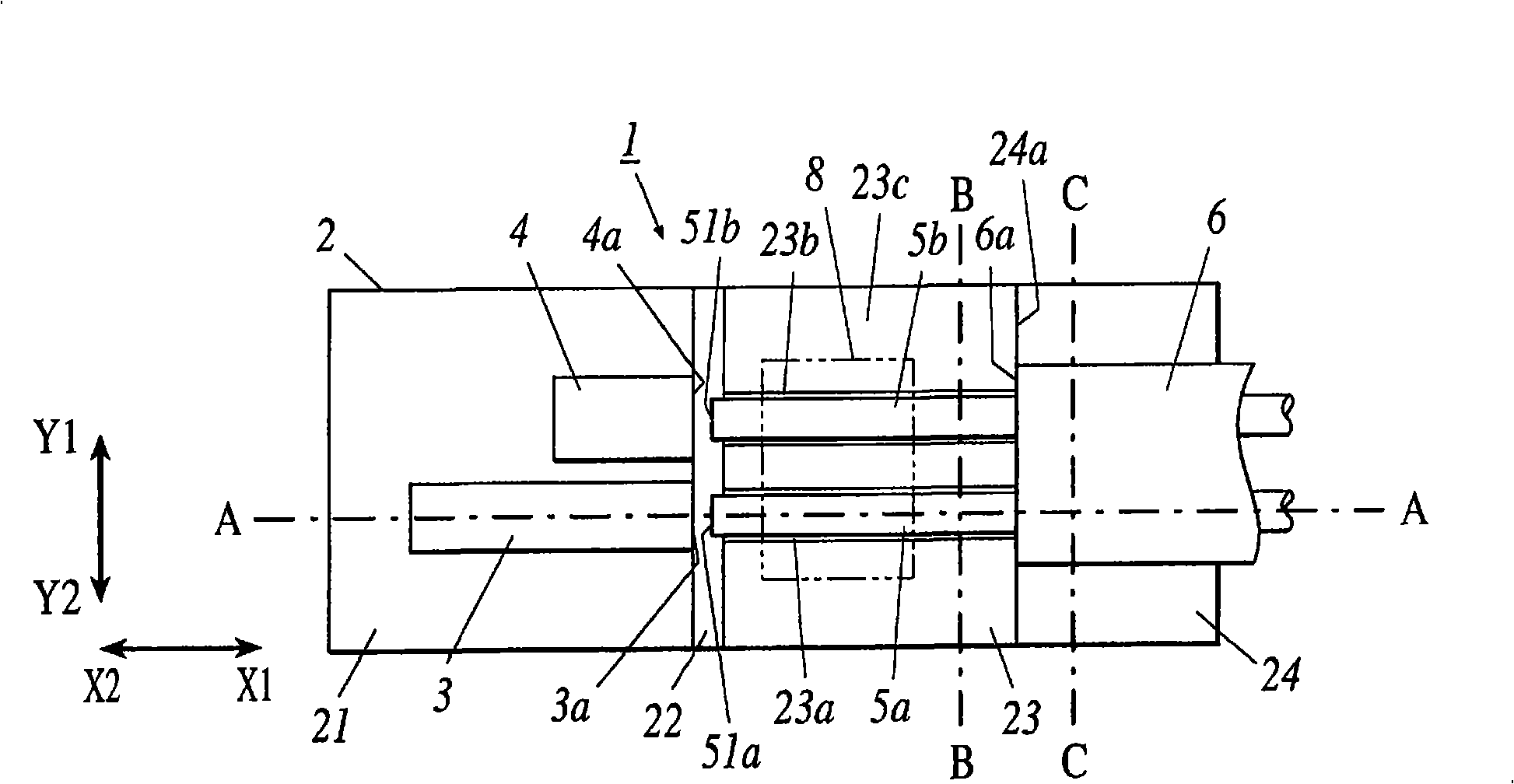

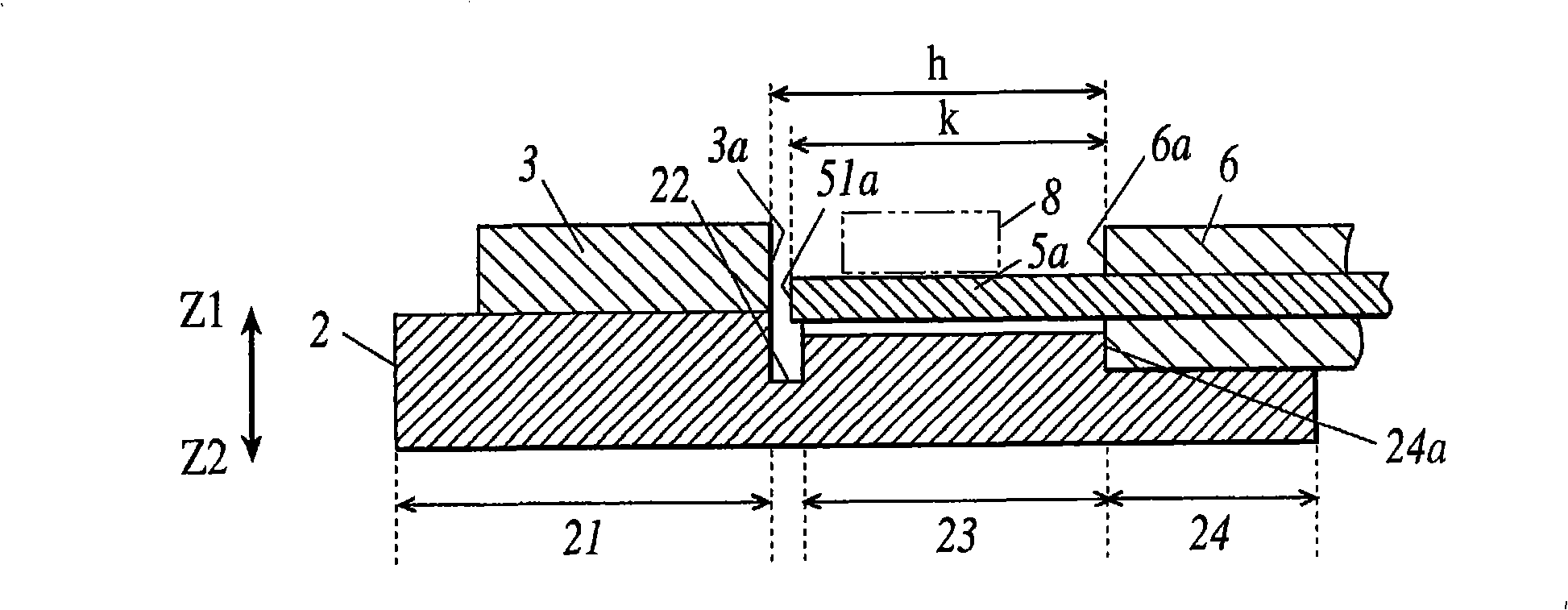

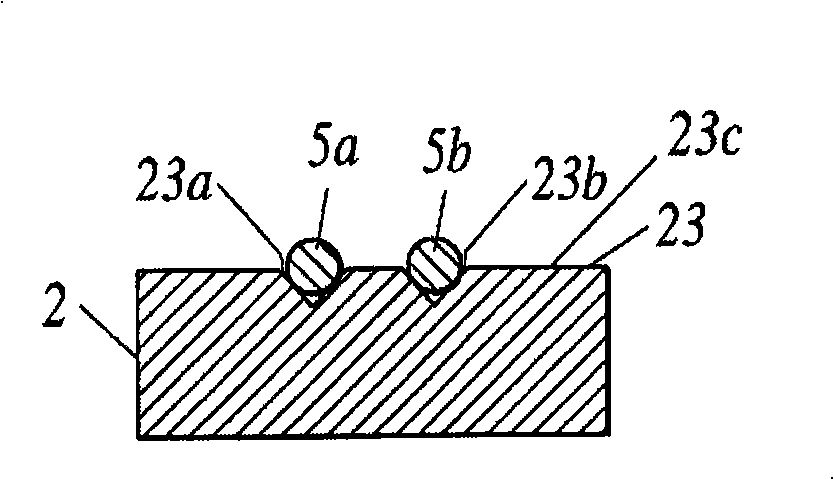

[0040] Figure 1A is a plan view showing the optical module 1 of the first embodiment, Figure 1B yes Figure 1A The A-A line sectional view, Figure 1C yes Figure 1A The end view of the B-B line, Figure 1D yes Figure 1A The end view of the C-C line.

[0041] Such as Figure 1A As shown, the optical module 1 is configured by mounting PD3, LD4, and optical fibers 5a, 5b on a substrate 2. The optical fibers 5a, 5b are covered by the covering part 6, and are partially exposed. The exposed portions of the optical fibers 5a, 5b are fixed with a cover glass 8 from above.

[0042] The substrate 2 is a plate-shaped substrate formed of single crystal silicon (Si), and as Figure 1A and Figure 1B As shown, it is composed of an optical component placement part 21 , a groove part 22 , a V-groove forming part 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com