Heat setting method for elastic cotton bra cup

A heat-setting, cotton-textured technology, applied in bras, bras, clothing and other directions, can solve the problems of substandard quality of non-woven fiber elastic cotton bras, affecting the working environment, and high energy consumption, and achieve the expansion of application varieties, wearing comfort, Process saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The development and application of elastic cotton cup bras is not suitable for traditional techniques. This is also the problem that the industry has not been able to popularize and apply despite years of hard work. In recent years, the applicant has been devoting himself to the research and exploration of a new technology for the industrialization of pure elastic cotton bra cups through research and practice, and has made new progress now.

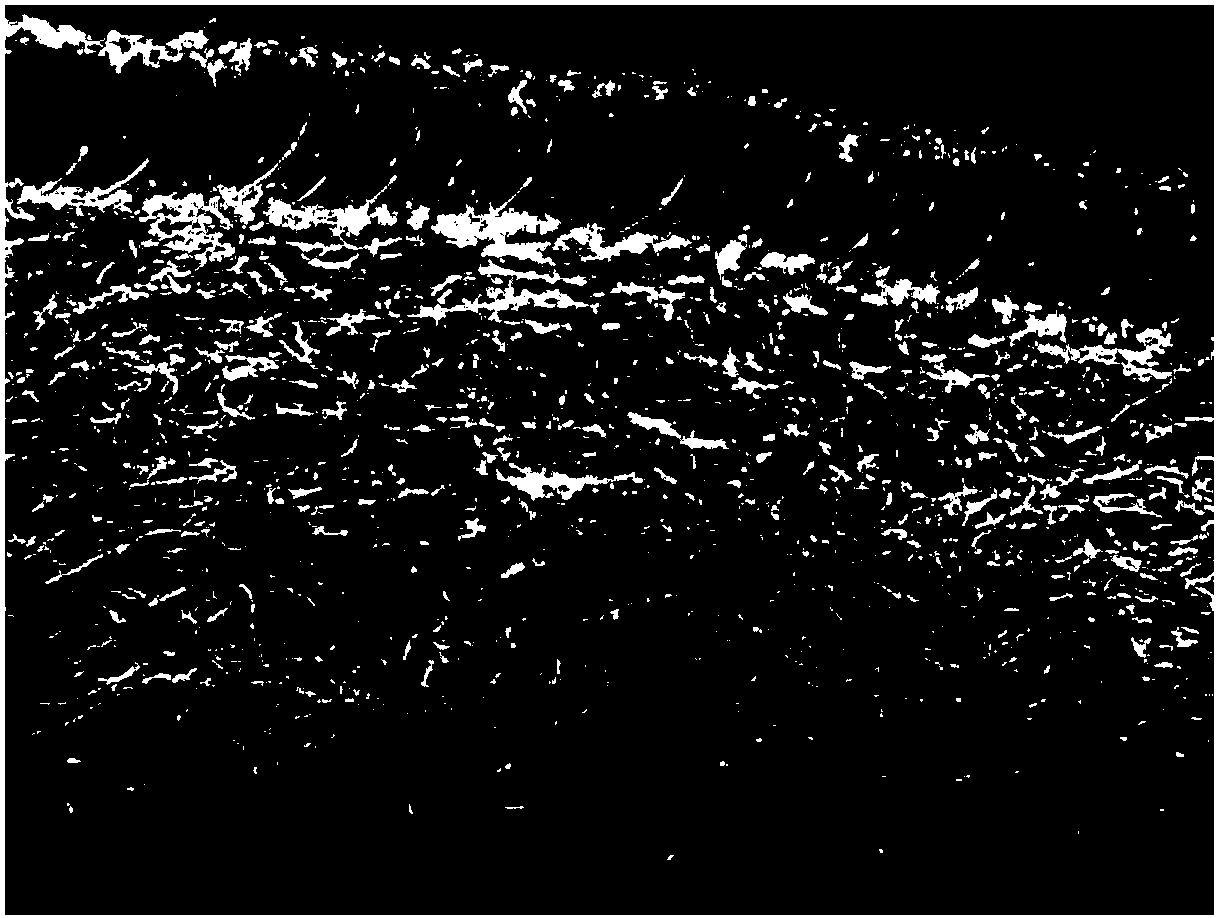

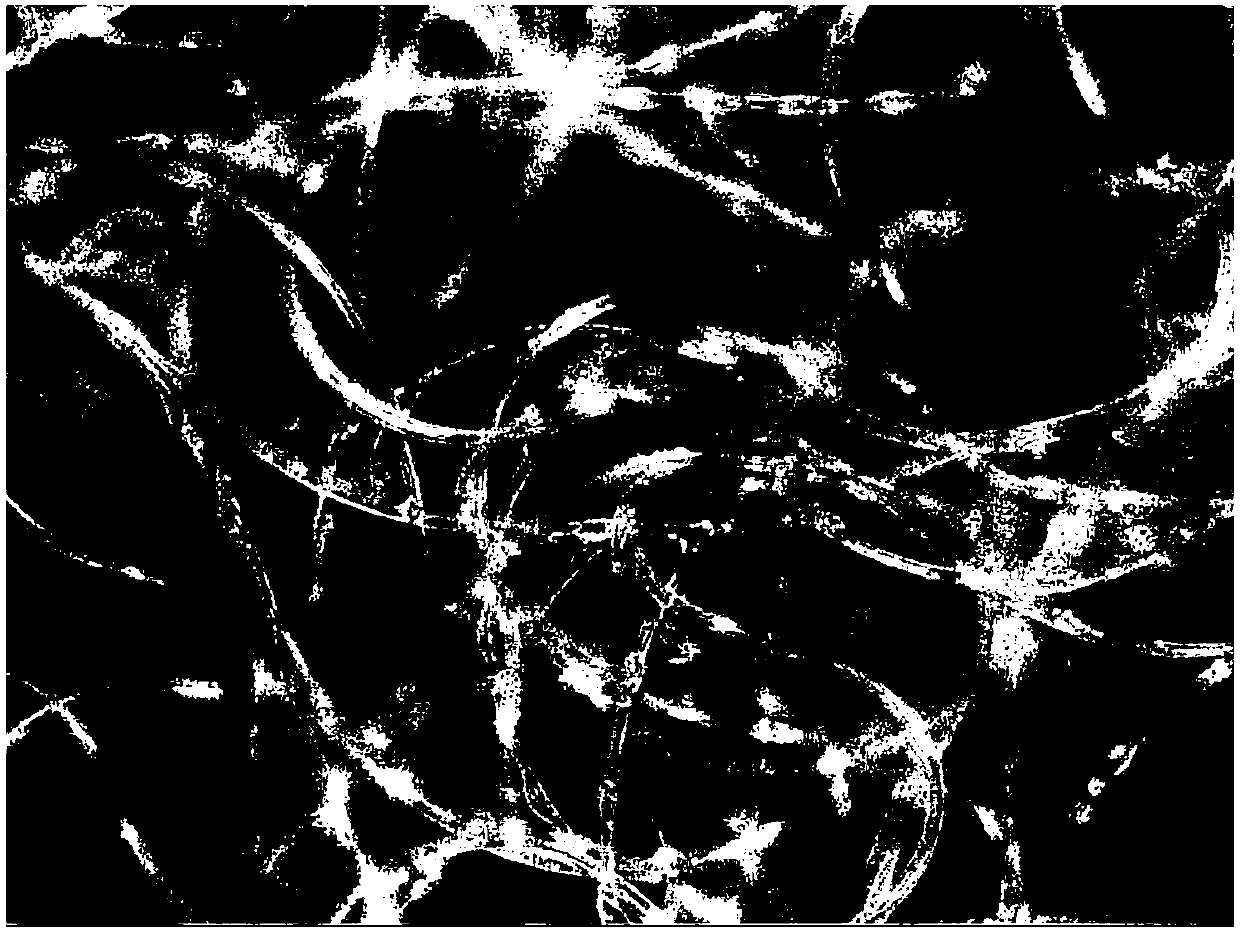

[0026] By observing and studying the microstructure of elastic cotton, testing the thermal characteristics of related high-tech functional fibers, and researching the thermal characteristics of cup fabrics, the applicant analyzed the reasons why traditional techniques failed for many years, and then explored a method that can protect elastic cotton. Innovative cup heat-setting process with structural fastness and elasticity—non-woven fiber elastic cotton bra cup heat-setting method, which is a low-temperature and low-pressure one-st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com