Automatic assembling equipment for optical fiber connector

An optical fiber connector, automatic assembly technology, applied in metal processing equipment, assembly machines, manufacturing tools and other directions, can solve the problems of low manual assembly efficiency, high connection reliability, low quality, etc., to achieve compact structure, improve assembly efficiency, The effect of shortening the workflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

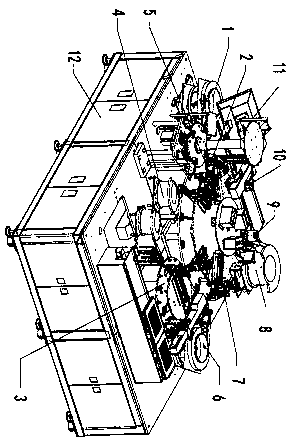

[0037] like figure 1 Shown, an embodiment 1 of the present invention is:

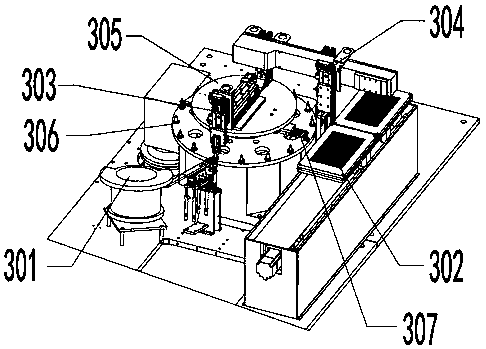

[0038] An automatic assembly equipment for optical fiber connectors, including a frame 12, three rotating disks are arranged on the left side of the top plate of the It is used to fix the second rotating disk of each clamping mechanism and the third rotating disk for arranging a plurality of first positioning seats. The lower part of the frame 12 is provided with an electric control system and an air storage tank for providing air pressure; the frame The right side of the top plate of 12 is provided with an optical fiber plug mechanism 3 for providing an optical fiber core and a guide tube assembly, and a plastic part feeding mechanism 1 and a spring feeding mechanism 4 are sequentially arranged on the top plate of the frame 12 along the rotation direction of the rotating disk , shell parts feeding mechanism 6, fastening sleeve feeding mechanism, dust cap feeding mechanism 8 and finished product receiv...

Embodiment 2

[0040] Embodiment 2: The lower end of the human-computer interaction display screen 11 is equipped with a display bracket, and a driven gear is connected to the lower end of the display bracket. One side of the driven gear is provided with a driving gear meshing with it. The shaft device is fixedly connected with the rotating motor, and the driving gear and the driven gear are fixed on the gear bracket.

[0041] The upper wall and the lower wall of the second rotating disk are sequentially provided with the first manipulator 2 for grabbing the plastic parts and placing them on the first positioning seat along the direction of rotation, and the first manipulator 2 for adjusting the position of the plastic parts. Two manipulators 5, a third manipulator 13 for making the spring at the center of the plastic part, a spring detection assembly for detecting whether the spring is placed in the plastic part, for grabbing the optical fiber core and the guiding tube assembly and placing i...

Embodiment 3

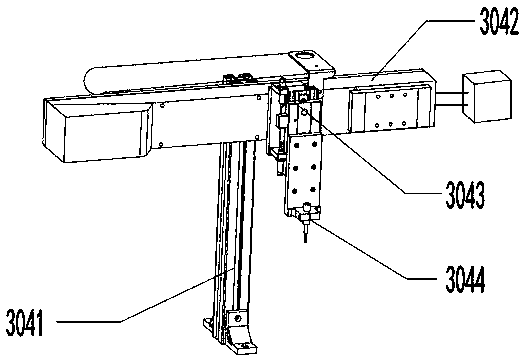

[0045] Embodiment 3: The optical fiber core horizontal assembly 3042 includes a rotating motor, a rolling screw, and a drag chain, and the fixed end of the rotating motor and the fixed end of the drag chain are both fixedly connected to the optical fiber core bracket 3041, so The working end of the rotating motor is fixedly connected to one end of the ball screw through a coupling, and the nut of the ball screw and the movable end of the drag chain are both fixedly connected to the fixed end of the optical fiber core lifting and moving assembly , the optical fiber core lifting and moving assembly moves horizontally driven by the rotating motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com