Driving motor cooling system with defrosting function and application method

A technology for driving a motor and a cooling system, which is applied in the arrangement of the cooling combination of the power unit, the cleaning of the power unit, and the vehicle, etc., can solve problems such as increasing energy consumption, avoid excessive inlet water temperature, and prevent the defroster from entering. The effect of low water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

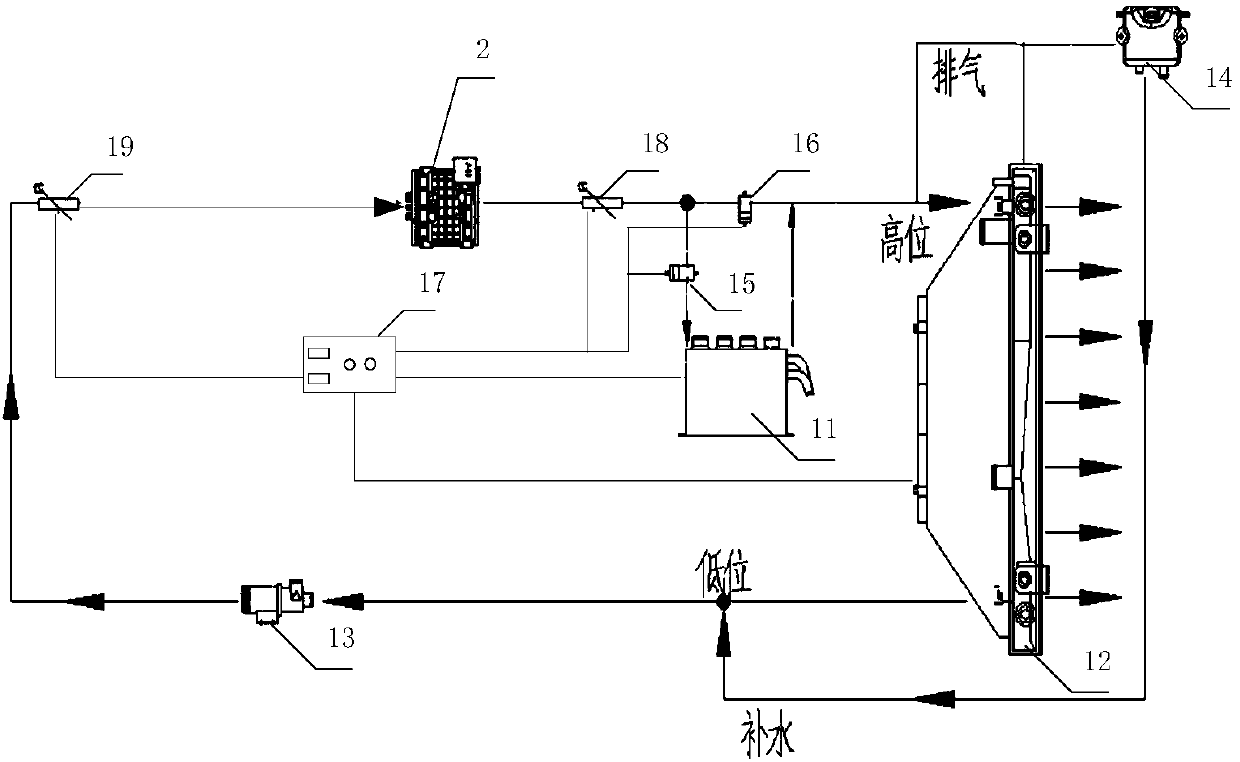

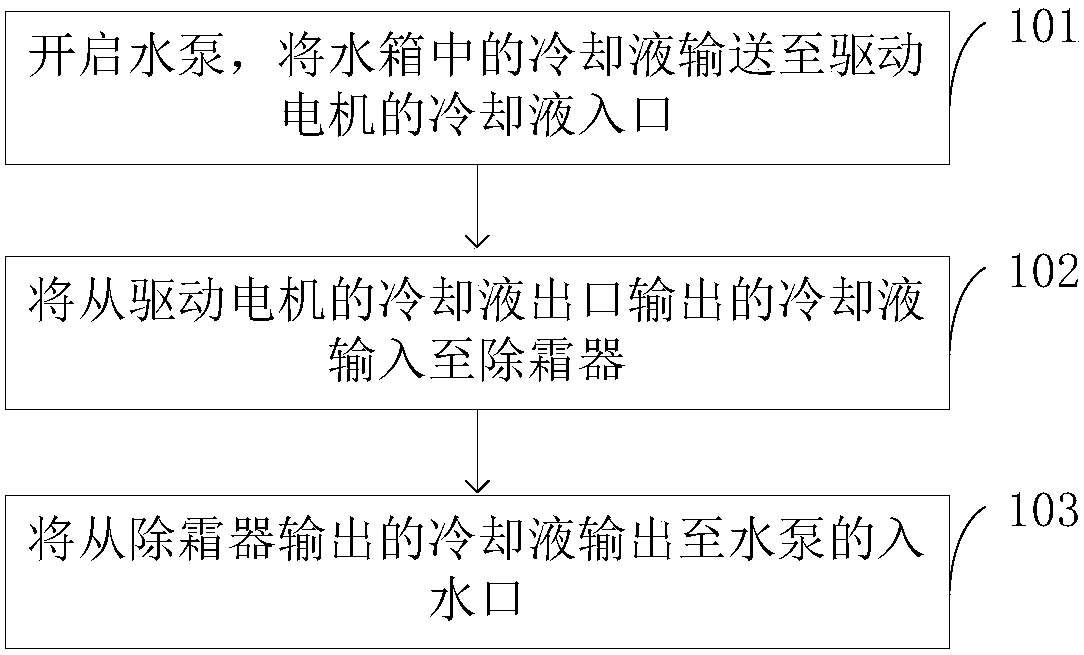

[0030] figure 1 A schematic structural diagram of a drive motor cooling system with a defrosting function provided in Embodiment 1 of the present invention; figure 1 As shown, the present embodiment provides a driving motor 2 cooling system with a defrosting function, including: a defroster 11, a radiator 12, a water pump 13 and a water tank 14, wherein the defroster 11 and the cooling liquid of the driving motor 2 The water inlet of outlet, radiator 12 is connected, and the water outlet of radiator 12 is connected with the water inlet of water pump 13, and the water outlet of water pump 13 is connected with the coolant inlet of drive motor 2, and the water inlet of water pump 13 is also connected with water tank 14.

[0031] Specifically, the defroster 11 can be a water-heating defroster 11 or a water-electric integrated defroster 11. The water pump 13 transports the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com