Two-section crawler sealed cabin air passage system

The technology of a tracked vehicle and a sealed cabin is applied in the engineering field, which can solve the problems of low heat dissipation efficiency, high engine water temperature, and poor watertight effect of the intake valve, and achieves the effect of high heat dissipation efficiency, avoiding excessive water temperature and good watertight effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with the best embodiment.

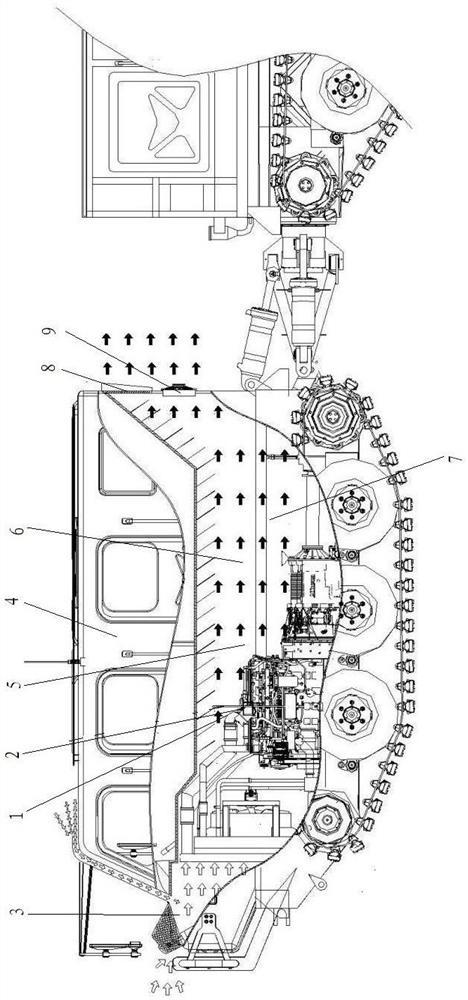

[0017] Such as figure 1 As shown, a double-joint tracked vehicle airtight cabin airway system is composed of an air intake end, an air duct and an exhaust end; 1 is equipped with an automatic control water-sealed intake valve 2, and the automatic control water-sealed intake valve 2 is automatically controlled by an electric control push rod or a hydraulic control push rod. The control button for automatically controlling the water-sealed intake valve 2 is set in the cab; the intake end also includes an auxiliary air intake 3 arranged at the front end of the double-section crawler vehicle body, and the opening of the auxiliary air intake is located at the wading area of the double-section crawler vehicle. Above the waterline. The air duct is composed of the power cabin 5 and the interior of the double tracked vehicle body 4 and extends to the rear of the vehicle; the exhaust end is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com