Processing technology for triangle-gemstone-shape unit plates of glass curtain wall

A technology of glass curtain wall and processing technology, which is applied in the direction of walls, building components, buildings, etc., can solve the problems of single facade and internal space effect, the influence of permeability and viewing angle, and difficulty in meeting high-demand architectural effects, etc., to achieve Improve architectural effects and diversity, novel and unique structure, and wide field of view

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

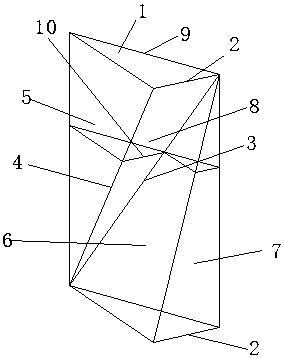

[0029] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0030] The invention provides a processing technology for a triangular jewel-shaped unit plate of a glass curtain wall, comprising the following steps:

[0031] 1) Profile opening;

[0032] 2) Weld unit frame 1, unit frame 1 is rectangular;

[0033] 3) Weld two vertical overhanging columns 2, diagonal columns 3, connecting beams 4 and two connected triangular supporting beams 10 on the unit frame 1;

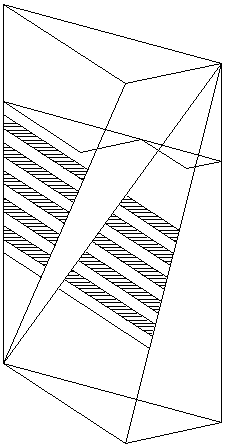

[0034]4) Make a single unit plate: install the vertical glass surface 5, the inclined glass surface 6, the vertical aluminum plate surface 7, the inclined aluminum plate surface 8 and the horizontal aluminum plate surface 9, and connect each surface with the unit frame 1, the external column 2, The diagonal column 3 and the connecting beam 4 are sealed, and a horizontal sliding waterproof structure is arranged on the rear side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com