Moving combing platform for detecting heating screen in circular fluidized bed boiler hearth

A technology of circulating fluidized bed and boiler furnace, which is applied in the direction of house structure support, house structure support, construction, etc., can solve the problems of high safety hazard in maintenance, shutdown, easy to leave defects, etc., and achieve the effect of comprehensive maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

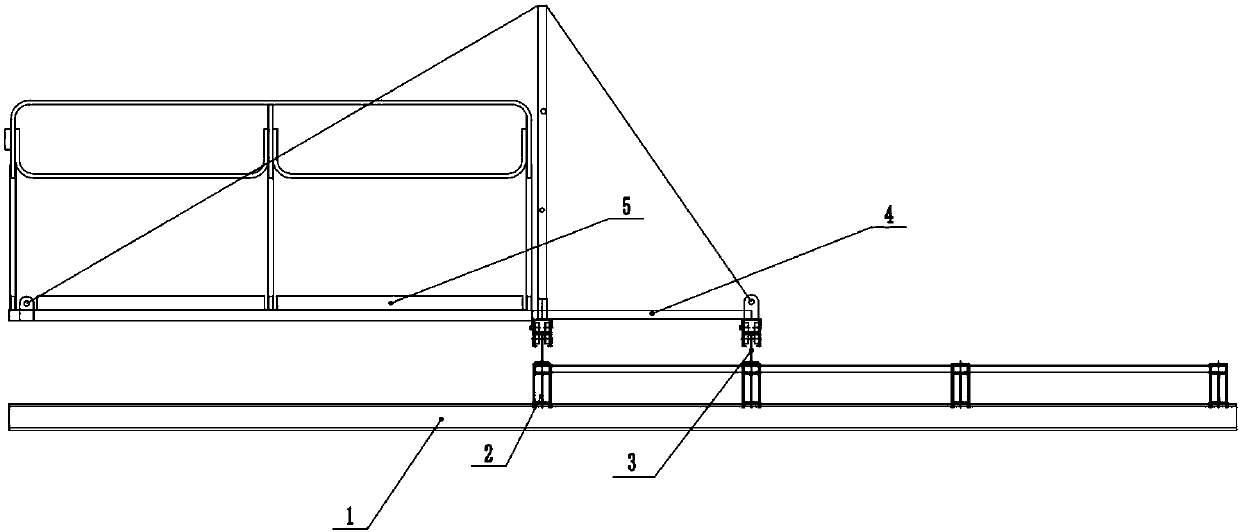

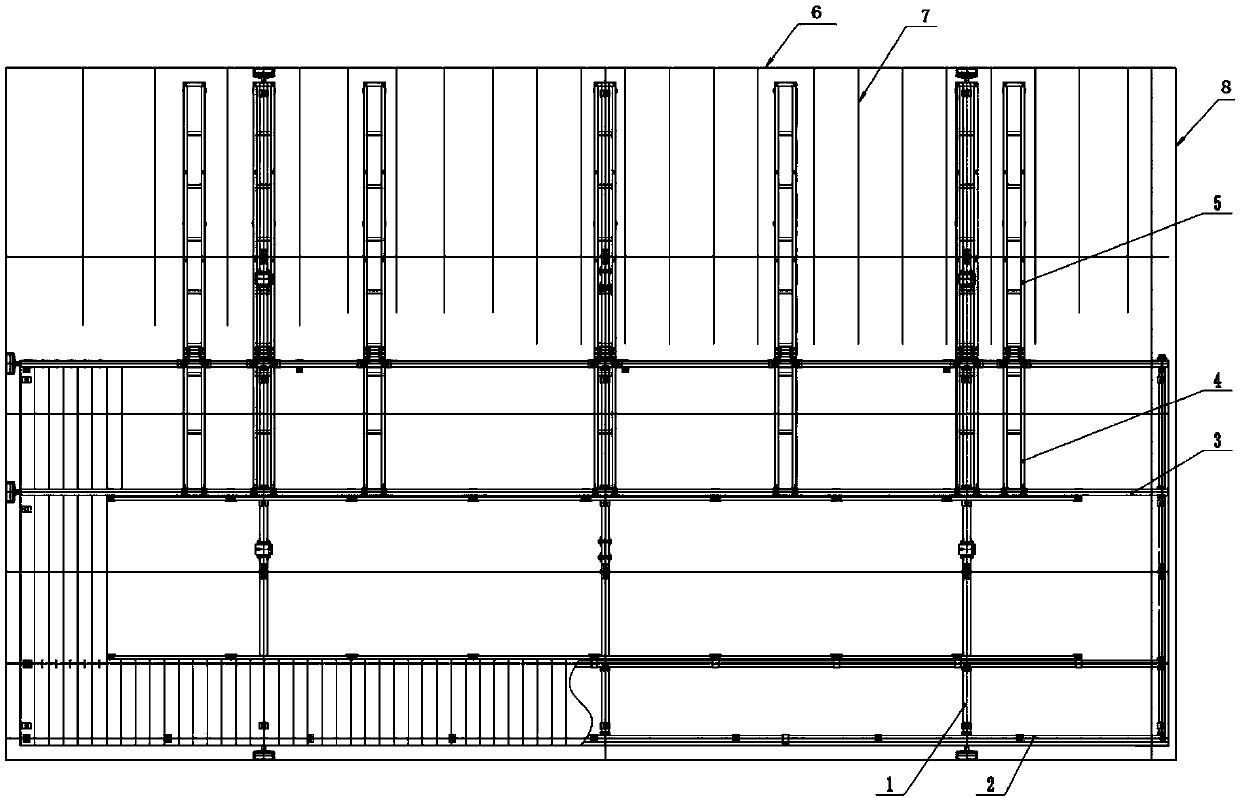

[0029] like figure 1 , figure 2 , overhaul the movable comb-shaped platform of the heating screen in the furnace of circulating fluidized bed boiler, including I-shaped main beam 1, I-shaped auxiliary beam 2, I-shaped guide rail beam 3, fixed movable platform 4 and comb-shaped movable platform 5 ;

[0030] The I-shaped main beam 1 is placed parallel to the furnace wall 8 on the left side of the boiler, the I-shaped sub-beam 2 is installed on the main beam 1 perpendicular to the main beam 1, and the main and sub-beams are connected by the main and sub-beam fasteners. The guide rail beam 3 is installed on the two auxiliary beams in front of the boiler, and the guide rail beam is connected with the auxiliary beam through guide rail fixing fasteners. figure 2 Middle 6 is the front wall of the boiler, and 7 is the heating hanging screen.

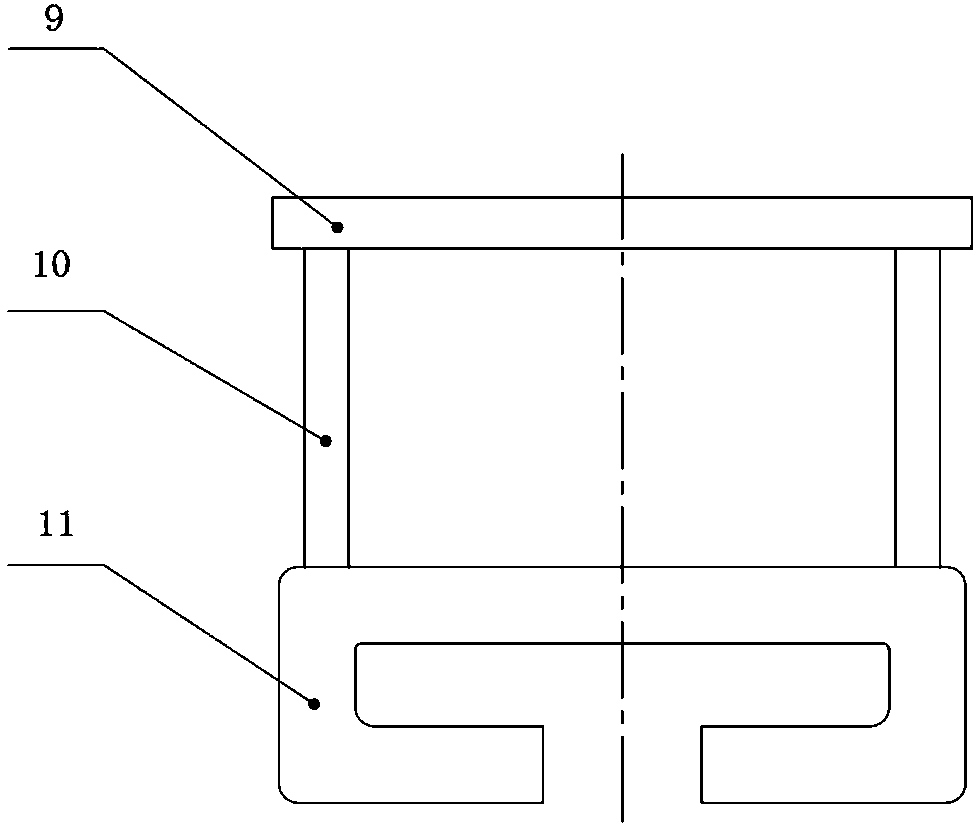

[0031] The fixed movable platform is connected with the comb-shaped movable platform and installed on the guide rail beam to realize the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com