Transformer gas relay pipeline structure

A gas relay and transformer technology, applied in transformer/inductor parts, electrical component structure associations, circuits, etc., can solve problems such as spending a few days, and achieve the effect of high utilization, simple production, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

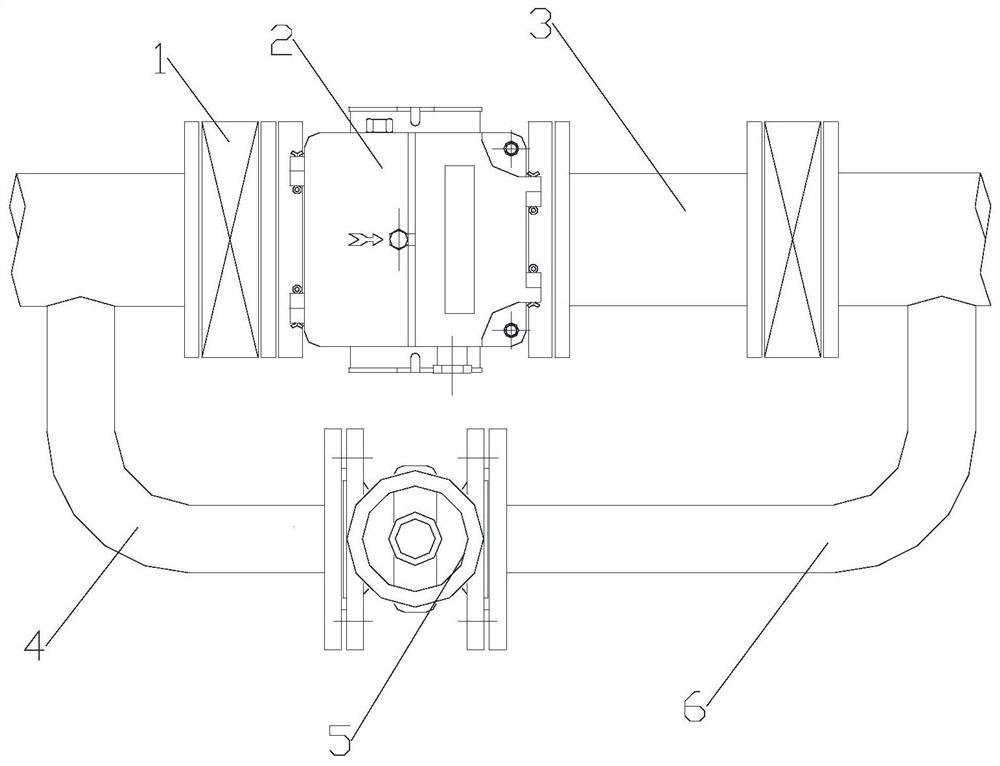

[0011]Such asfigure 1As shown, a pipeline structure at a transformer gas relay includes a gas relay 2, a DN80 butterfly valve 1 and a ZF50 gate valve 5; the two ends of the gas relay 2 are respectively connected to the transformer main gas collecting pipeline through a DN80 butterfly valve 1; The two ends of the ZF50 gate valve 5 are connected in parallel to the two ends of the gas relay 2 through the first pipe joint 4 and the second pipe joint 6 respectively.

[0012]Based on the above, the two DN80 butterfly valves 1 are located between the interface of the first pipe joint 4 and the main air collector of the transformer and the interface of the second pipe joint 6 and the main air collector of the transformer.

[0013]The first pipe joint 4 is welded to the main gas collector at the back end of the gas relay 2. A DN80 butterfly valve 1 is designed between the welding point and the gas relay 2; the second pipe joint 6 is welded to the main gas collector at the front end of the gas rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com