Automatic-control valve for automatically preparing solution

A technology of self-controlling valves and solutions, applied in the direction of sliding valves, valve details, valve devices, etc., can solve the problems of high labor intensity of operators, fluctuations in the quality of coal rods, and large investment in human resources, so as to reduce human resource input and improve retting Effect of coal quality and retting coal quality qualified

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

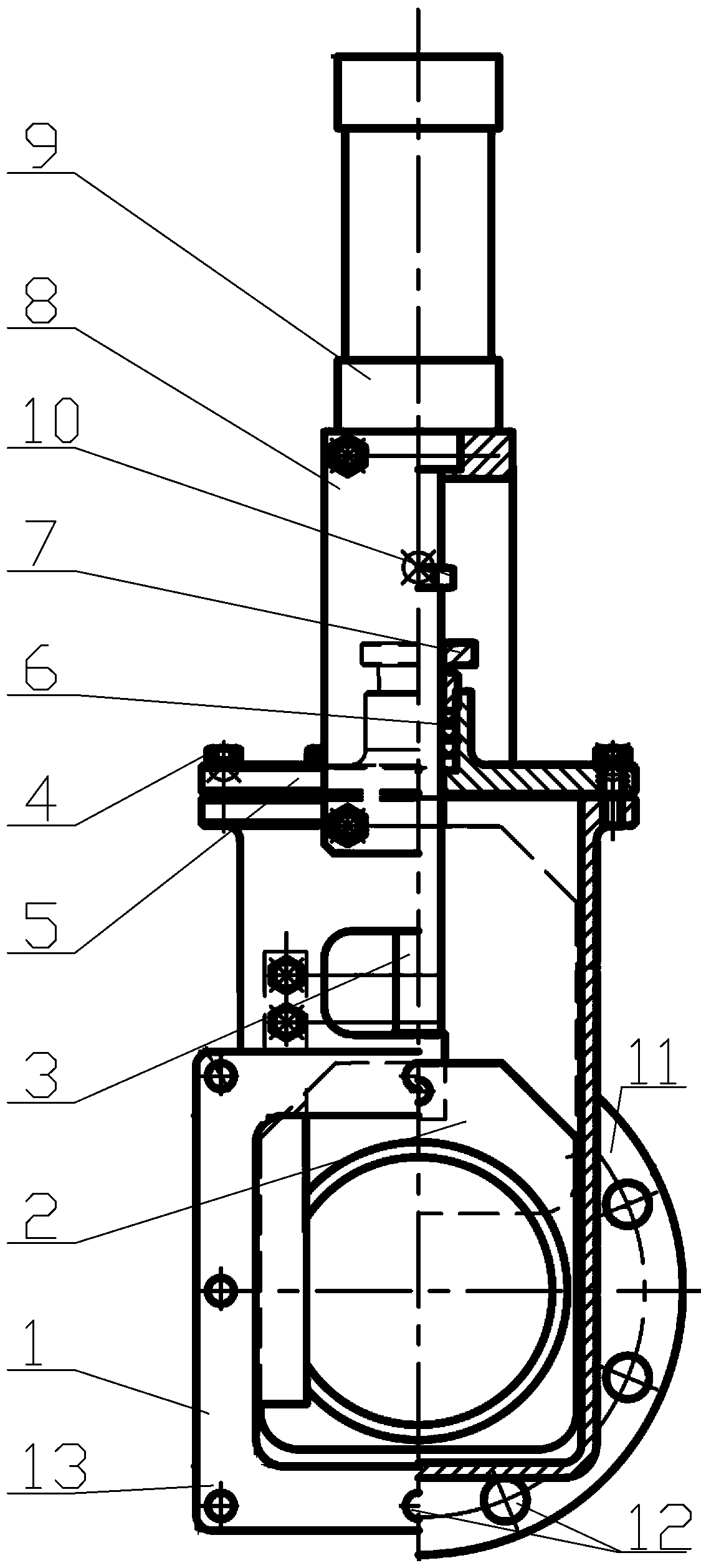

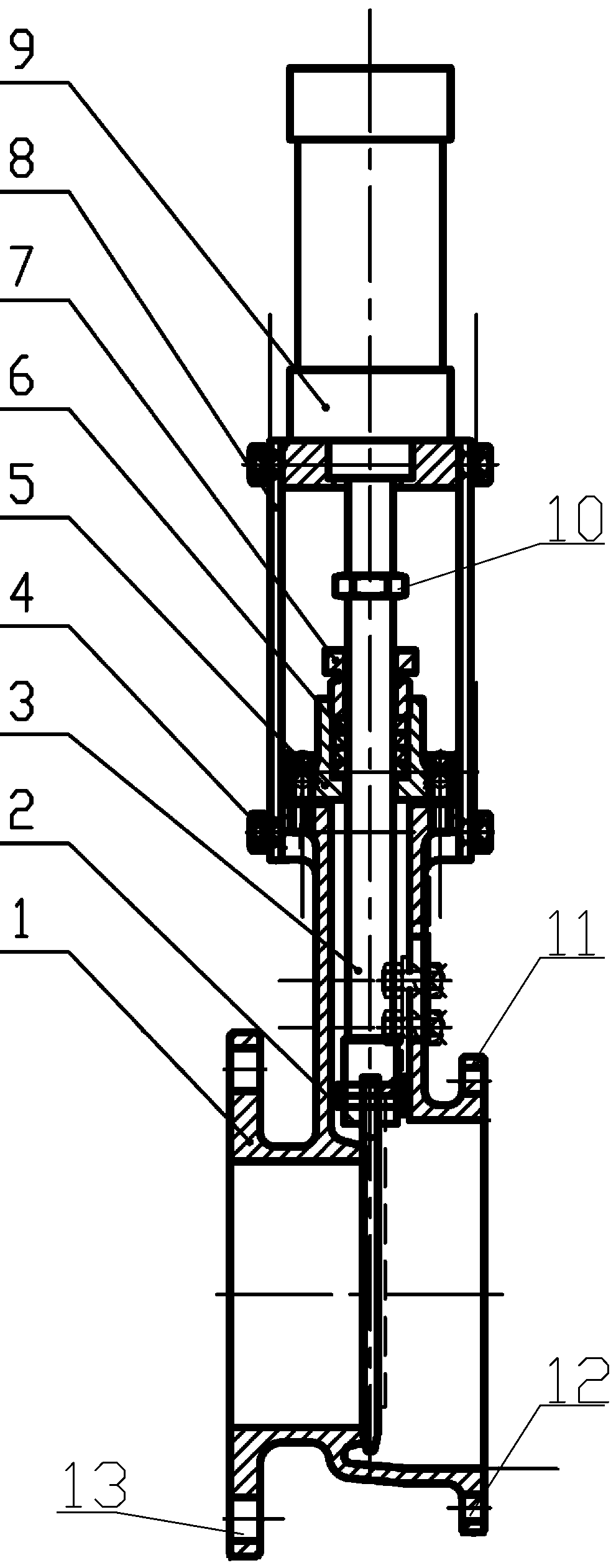

[0024] Such as Figure 1-2 As shown, a self-control valve for solution automatic configuration, it includes a valve body 1, a valve cover 5 is installed on the top of the valve body 1, the center of the valve cover 5 is processed with a boss, the boss of the The center is processed with a central hole, the top of the valve cover 5 is equipped with a support plate 8, the top of the support plate 8 is equipped with a cylinder 9, and the piston rod 3 of the cylinder 9 passes through the center hole of the central boss of the valve cover 5 , the end of the piston rod 3 is connected with a gate 2 , and the gate 2 is arranged inside the valve body 1 . By replacing the manual ball valve in the original pipeline with the current automatic control valve, unified remote control can be used, which ensures the stability and uniformity of the liquid dosing process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com