A kind of in situ controllable synthesis method of MOF film

A synthesis method and MOF technology, applied in the field of in-situ controllable synthesis of MOF membranes, can solve the problems of material, energy consumption, long and complicated preparation process, difficult limitation and regulation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Zn 2 (bim) 4 Preparation of molecular sieve membrane

[0034] Metal ion solution preparation: take 0.01116g of zinc nitrate hexahydrate, add 20ml of methanol to dissolve and set aside.

[0035] Organic ligand solution preparation: take 0.02890g of benzimidazole, add 20ml of methanol to dissolve and set aside.

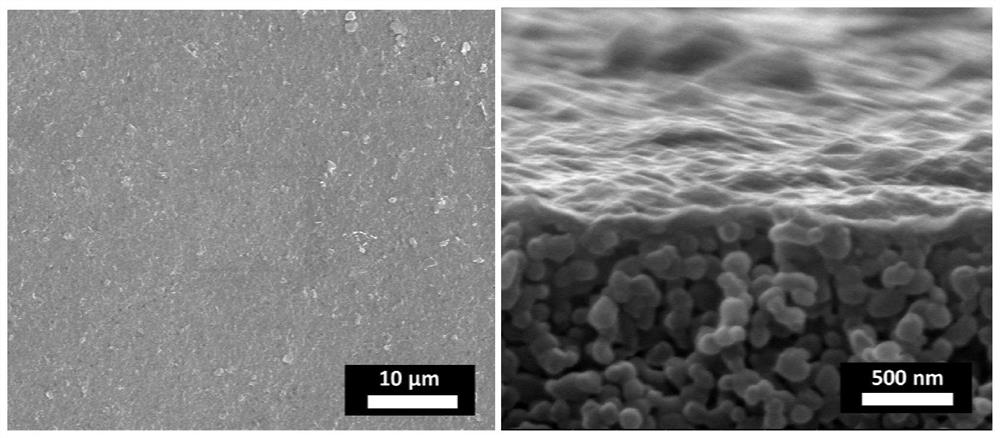

[0036] Carrier: a porous α-alumina disc with a diameter of 18mm and a thickness of 1mm. The carrier has an asymmetric structure. The surface pore size is about 70nm, which is the front side, and the bottom pore size is about 2μm, which is the back side. The carrier is used before use. deionized water and acetone, and then dried before use.

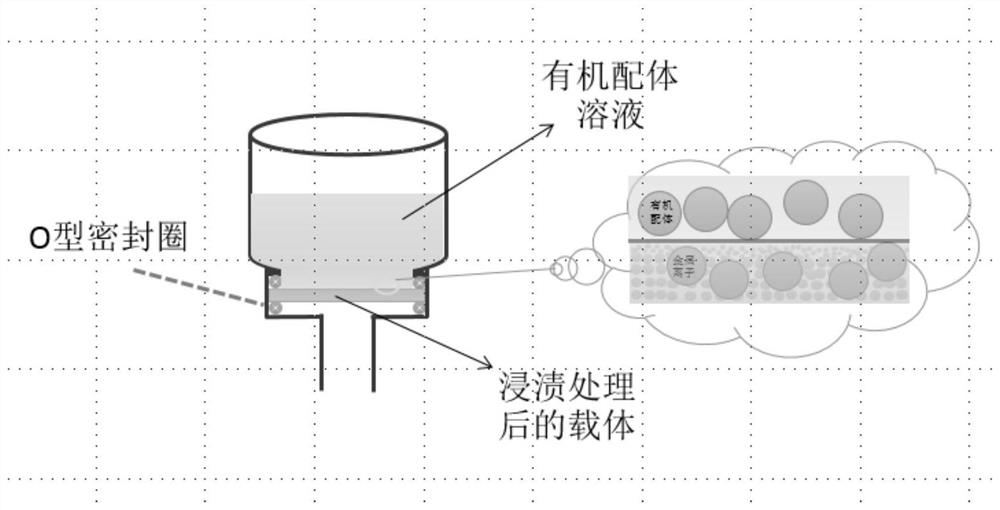

[0037] The carrier impregnation method is negative pressure solution filtration, that is, the carrier is fixed on the device (such as figure 1 The device shown), face up, add the metal ion solution above the carrier, and then filter with suction to make the solution permeate from the carrier.

[0038] Reaction: add the o...

Embodiment 2

[0044] Zn 2 (bim) 4 Preparation of molecular sieve membrane

[0045] Metal ion solution preparation: take 0.01116g of zinc nitrate hexahydrate, add 20ml of methanol to dissolve and set aside.

[0046] Organic ligand solution preparation: take 0.02890g of benzimidazole, add 20ml of methanol to dissolve and set aside.

[0047] Carrier: a porous α-alumina disc with a diameter of 18mm and a thickness of 1mm. The carrier has an asymmetric structure. The surface pore size is about 70nm, which is the front side, and the bottom pore size is about 2μm, which is the back side. The carrier is used before use. deionized water and acetone, and then dried before use.

[0048] According to the same operation as in Example 1, the number of reactions is changed, that is, the membrane after impregnation, reaction, and cleaning is fixed again, and the process of impregnation, reaction, and cleaning is repeated once or twice, and finally the membrane is dried to obtain Zn 2 (bim) 4 Molecular...

Embodiment 3

[0051] Zn 2 (bim) 4 Preparation of molecular sieve membrane

[0052] Preparation of metal ion complex solution: zinc porphyrin / DMF, concentration 0.02mol / L, stir well and set aside.

[0053] Organic ligand solution preparation: benzimidazole / methanol, 0.026mol / L, stir well and set aside.

[0054] Carrier: a porous α-alumina disc with a diameter of 18mm and a thickness of 1mm. The carrier has an asymmetric structure. The surface pore size is about 70nm, which is the front side, and the bottom pore size is about 2μm, which is the back side. The carrier is used before use. deionized water and acetone, and then dried before use.

[0055] The carrier impregnation method is solution pulling impregnation, that is, the carrier is fixed on the pulling machine, and the Zn 2+ - Lifting with porphyrin solution, the lifting can be repeated many times, and drying is carried out after the lifting is completed.

[0056] Reaction: add the organic ligand solution directly on the impregnate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com