Panel detection jig and method

A panel inspection and fixture technology, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve the problems of uneven product qualification rate, high operator intensity, and dependence on the operator's technical level and proficiency, etc. Optimize, improve detection accuracy, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

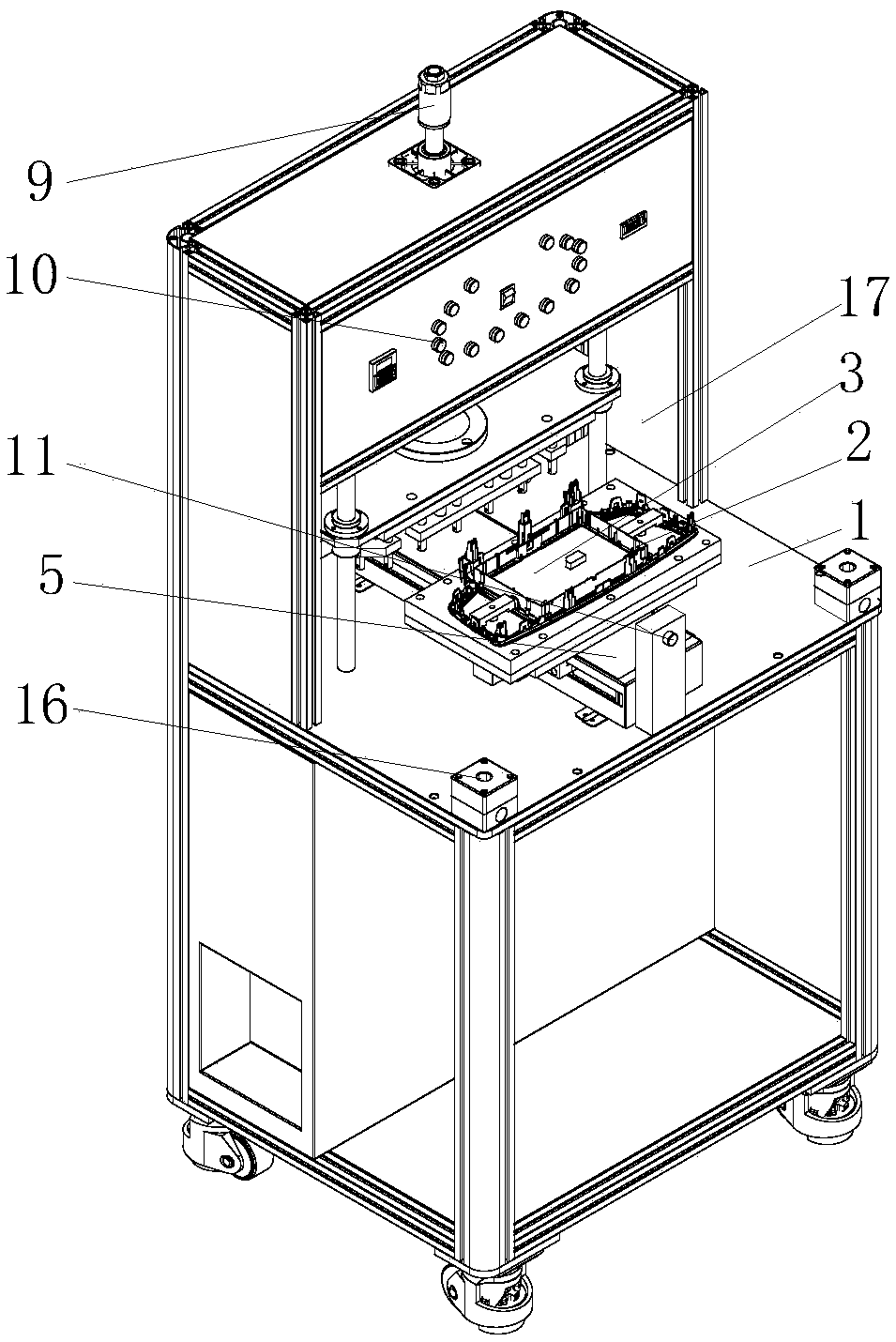

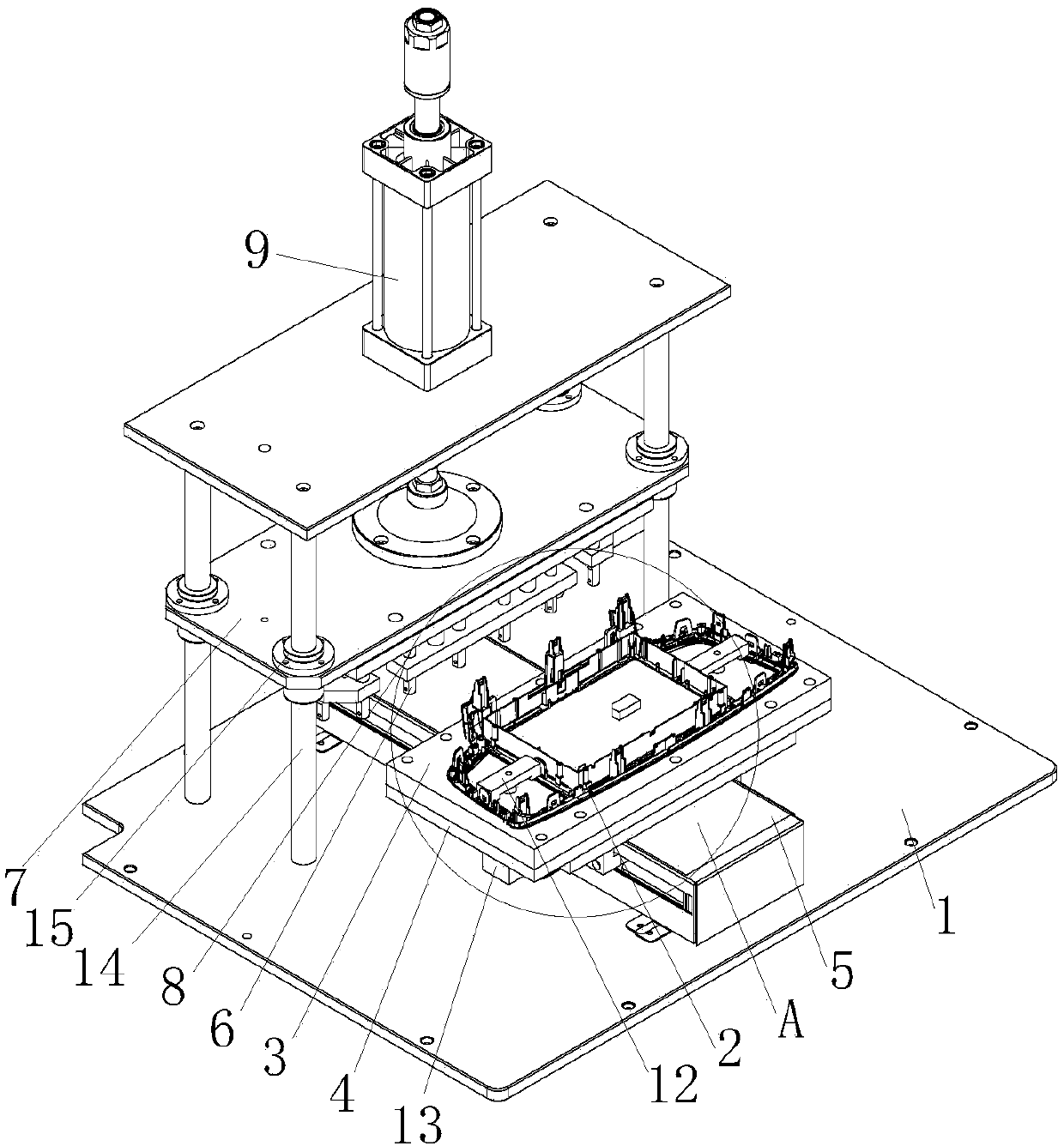

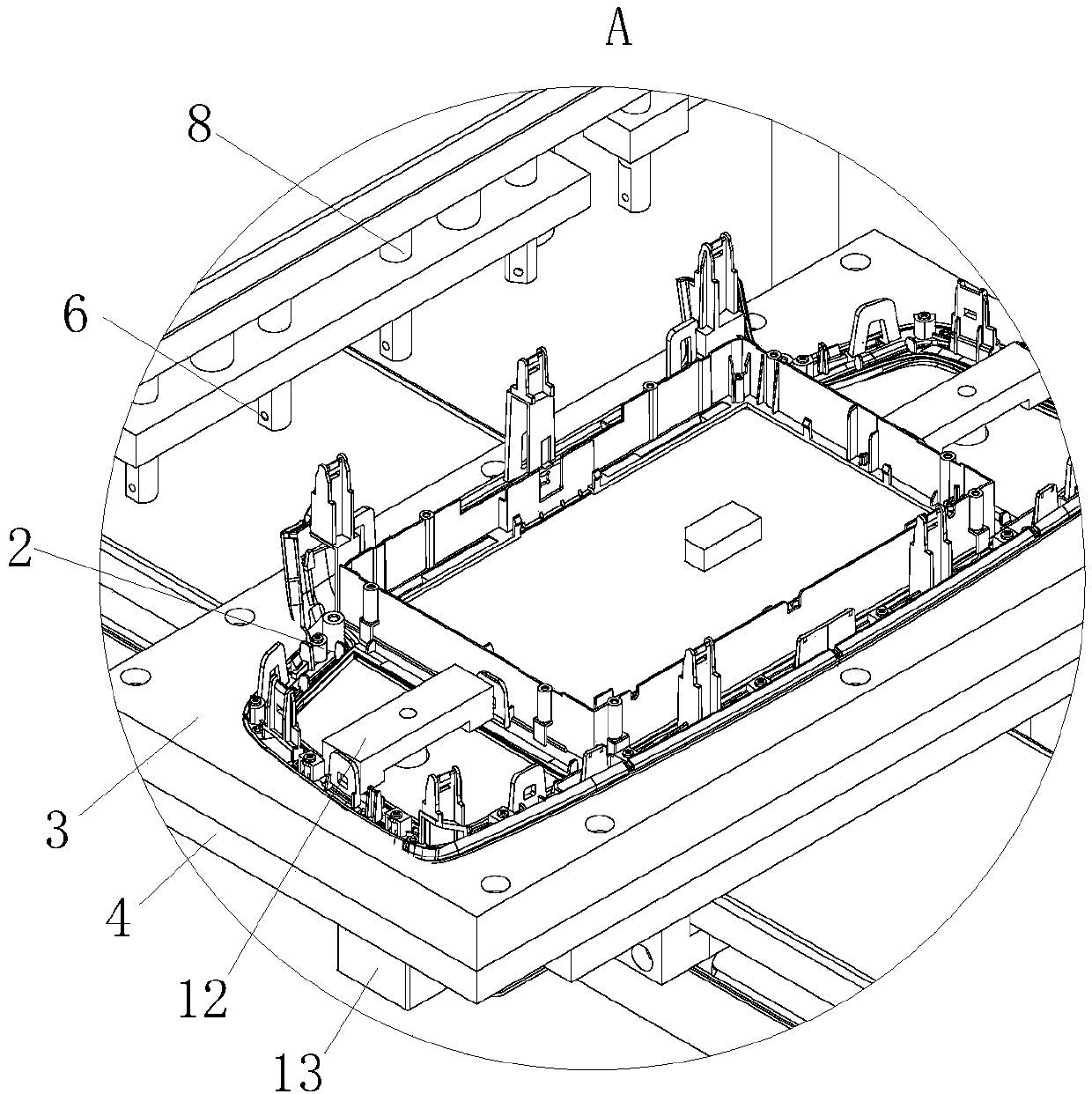

[0024] combine Figure 1 to Figure 3 As shown, the present invention discloses a panel inspection fixture, which includes a bottom plate 1, a receiving unit, a first driving unit, a testing unit and a second driving unit. The receiving unit is used to receive and fix the panel 2 and can move horizontally relative to the bottom plate 1 , which includes a receiving plate 3 for receiving the panel 1 and a pressing assembly for fixing the panel 2 . The receiving plate 3 is provided with a profiling groove for fitting the panel 2 . Through the pressing assembly and the profiling groove, it is ensured that the panel 2 and the receiving plate 3 will not change in relative displacement d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com