Automatic riveting machine for power line plug inner frame

A technology for power cords and riveting machines, which is applied to circuits, connections, electrical components, etc., can solve problems such as low work efficiency, people are prone to fatigue, and the risk of work-related injuries, so as to reduce labor costs, facilitate post-processing, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

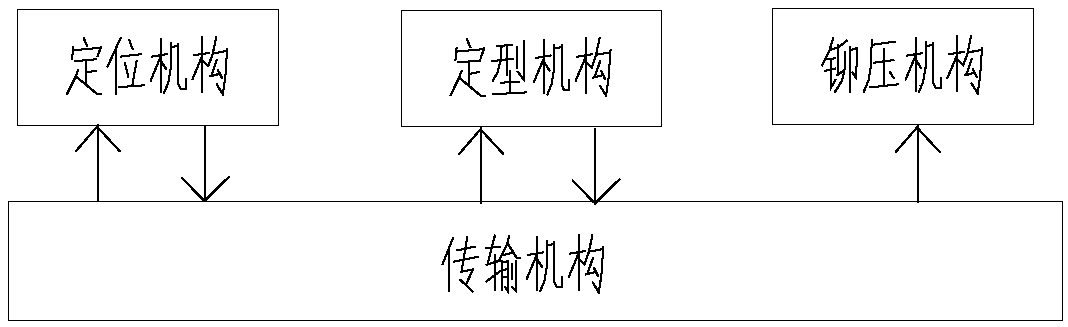

[0054] Such as figure 1 As shown, an automatic riveting machine for the inner frame of a power cord plug, including a transmission mechanism 1 for conveying the power cord, a positioning mechanism 2 for identifying and positioning the core wire of the power cord according to the color of the core wire, and a positioning mechanism for positioning the positioned core wire The shaping mechanism 3 for splitting and shaping and the riveting mechanism 4 for riveting the shaped core wire with the plug inner frame; the positioning mechanism, shaping mechanism and riveting mechanism are sequentially arranged on one side of the transmission mechanism, and the transmission mechanism will The power cords processed by different processes are transported to the mechanism of the next process for processing.

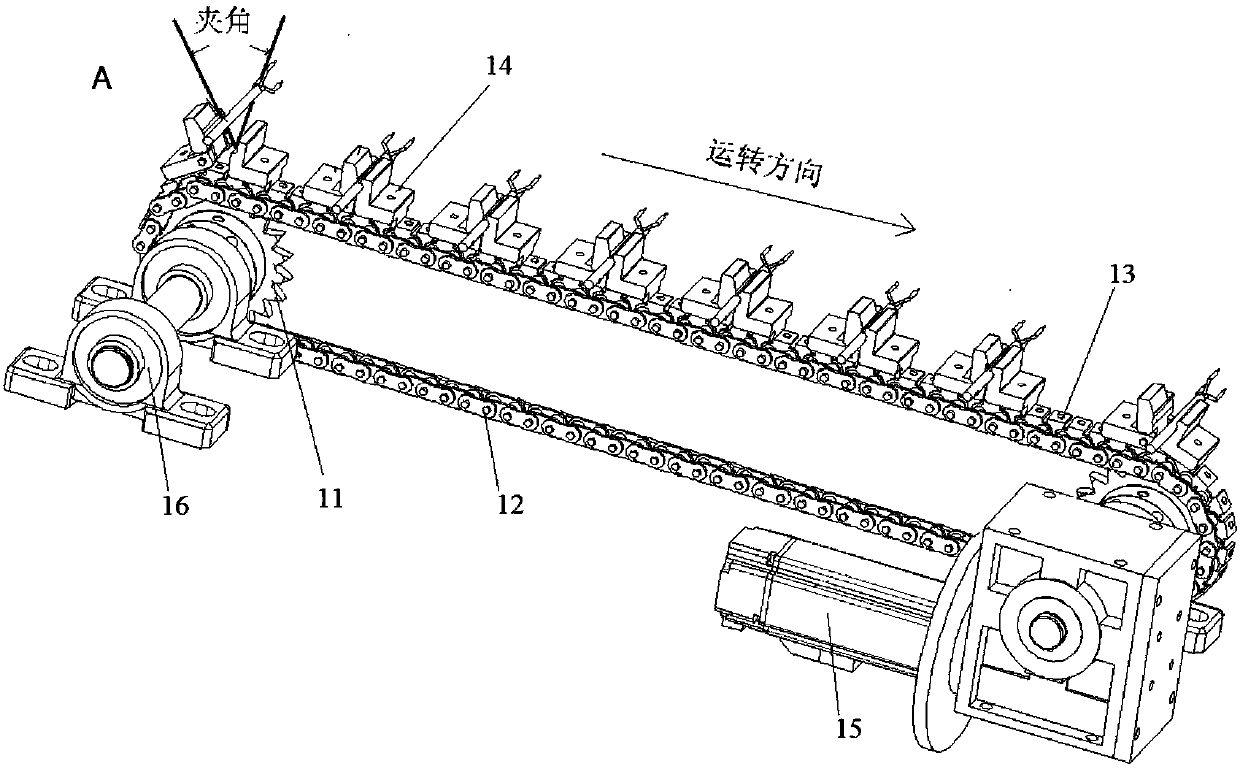

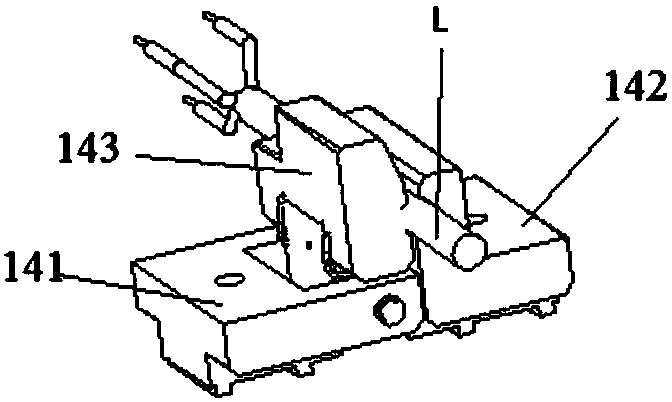

[0055] Among them, such as Figure 2-4 As shown, the tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com