Floating location chassis riveting tool

A positioning machine and riveting technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electric components, etc., can solve the problems of non-vertical, complex mold structure, low riveting efficiency, etc., to achieve convenient and smooth removal, convenient operation, avoid The effect of positioning influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, various embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

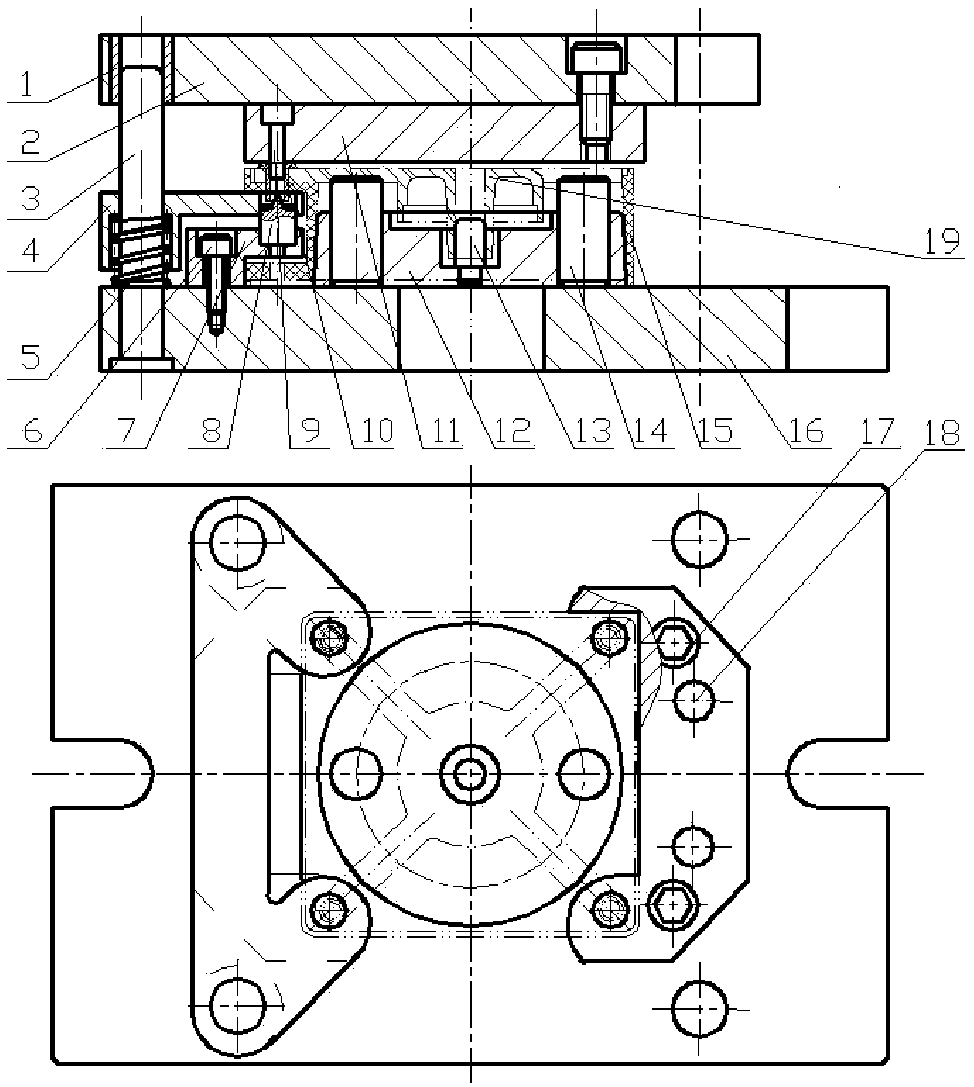

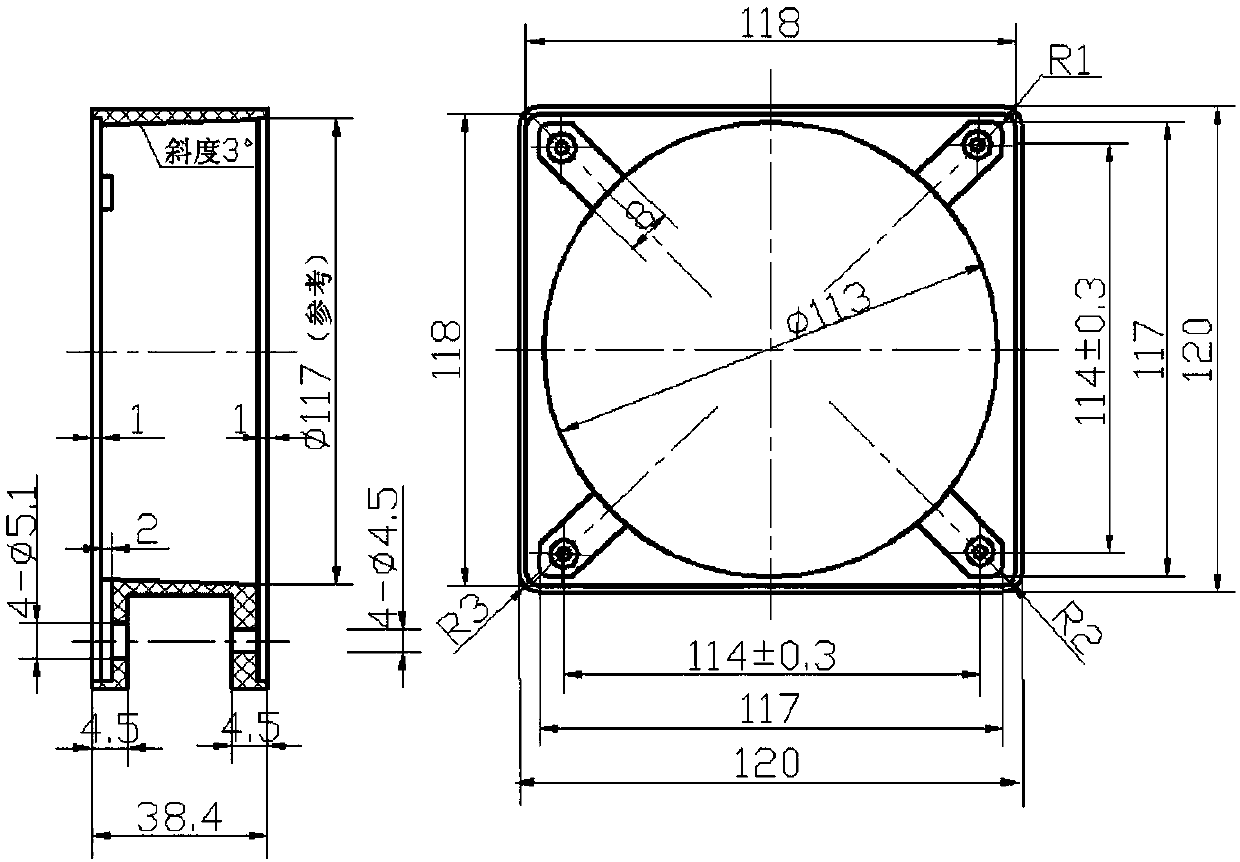

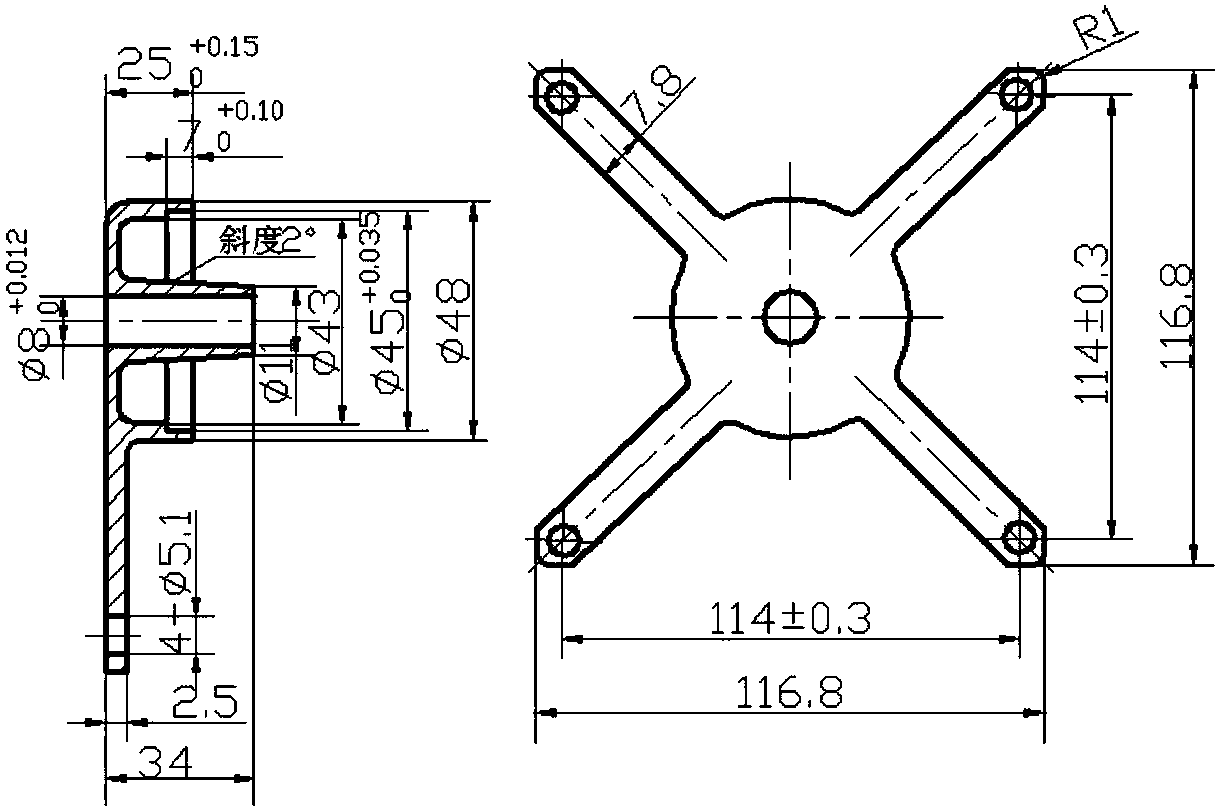

[0036] Please refer to the following Figure 1 to Figure 12 , a floating positioning casing riveting tooling (such as figure 1 Shown), used for casing 15 (such as figure 2 shown) and stator core support 19 (such as image 3 shown) through hollow rivets 10 (such as Figure 12 Shown) riveted to form a combined casing structure (such as Figure 4 shown), the riveting tooling includes an upper die set, a lower die set, a bracket hole positioning core 13, a floating positioning core 12 on the inner edge of the casing, a limit post 14 and a riveting claw 8 (such as Figure 9 As shown), place several forks of the stator core support 19 in several grooves of the casing 15, and after aligning with the corresponding mounting holes, insert the hollow rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com