Warning device of negative pressure dust removing system

A technology for a dust removal system and a warning device, which can be used in the fields of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., and can solve problems such as hidden safety hazards and large machine loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

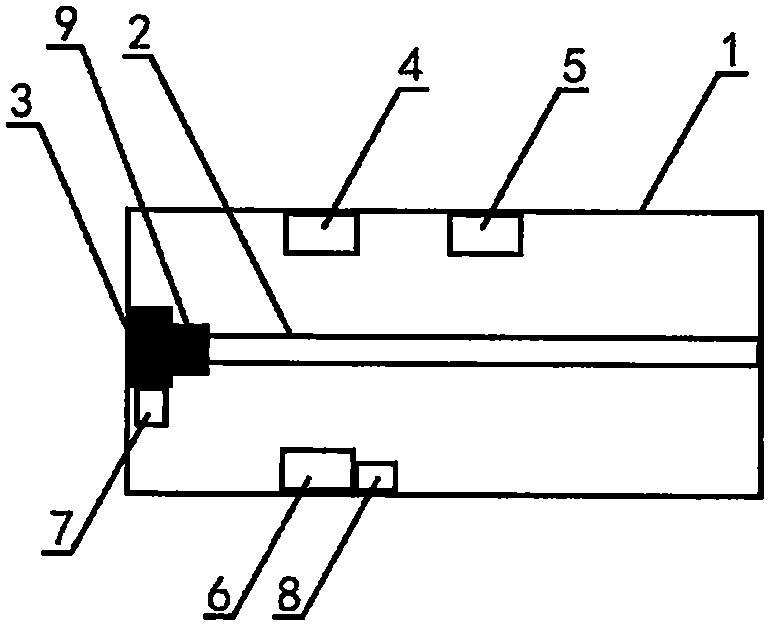

[0012] Embodiment: as shown in the accompanying drawing. A warning device for a negative pressure dust removal system, comprising a body (1), on which a dust suction pipe channel (2), a dust collection module (3), an infrared sensor (4), and a remote communication module (5 ), the management module (6), during operation, the dust collection module (3) will process the scraps collected from the dust suction channel (2), and the infrared sensor (4) will sense the chips entering the dust suction tube (2) The size and operation status of the end, the sensed information is transmitted to the management module (6) through the remote communication module (5) for processing.

[0013] A warning device for a negative pressure dust removal system, in which an operation sensing module (7) is arranged on a dust collecting module (3) to sense whether chips enter and output in time.

[0014] A warning device for a negative pressure dust removal system is provided with a prompting module (8)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com