Copper bar punching die

A technology of punching and mold, which is applied in the field of copper bar production, can solve the problems of slow adjustment speed of copper bar or bus bar, expensive bus bar shearing machine, low efficiency of copper bar punching, etc., and achieves production cost reduction and structure Simple, Quick Dimensional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

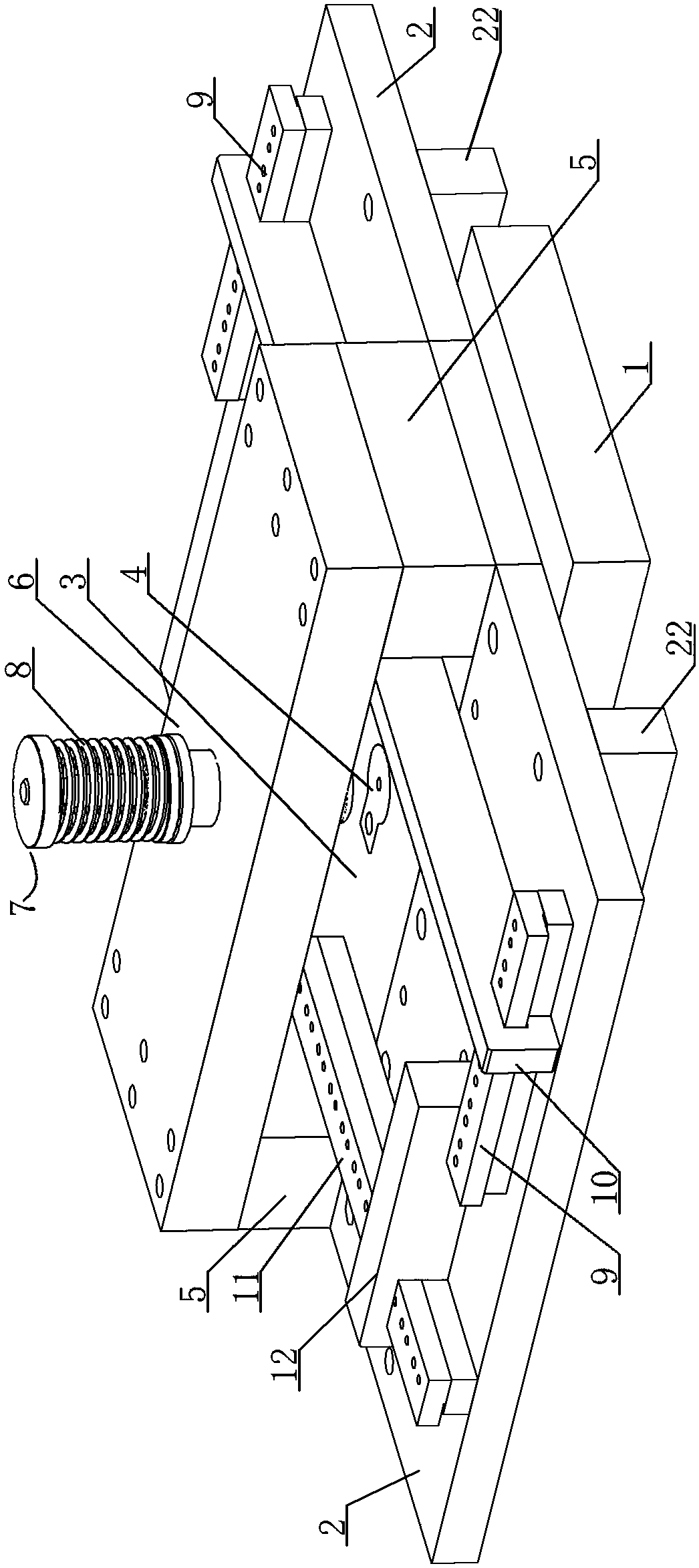

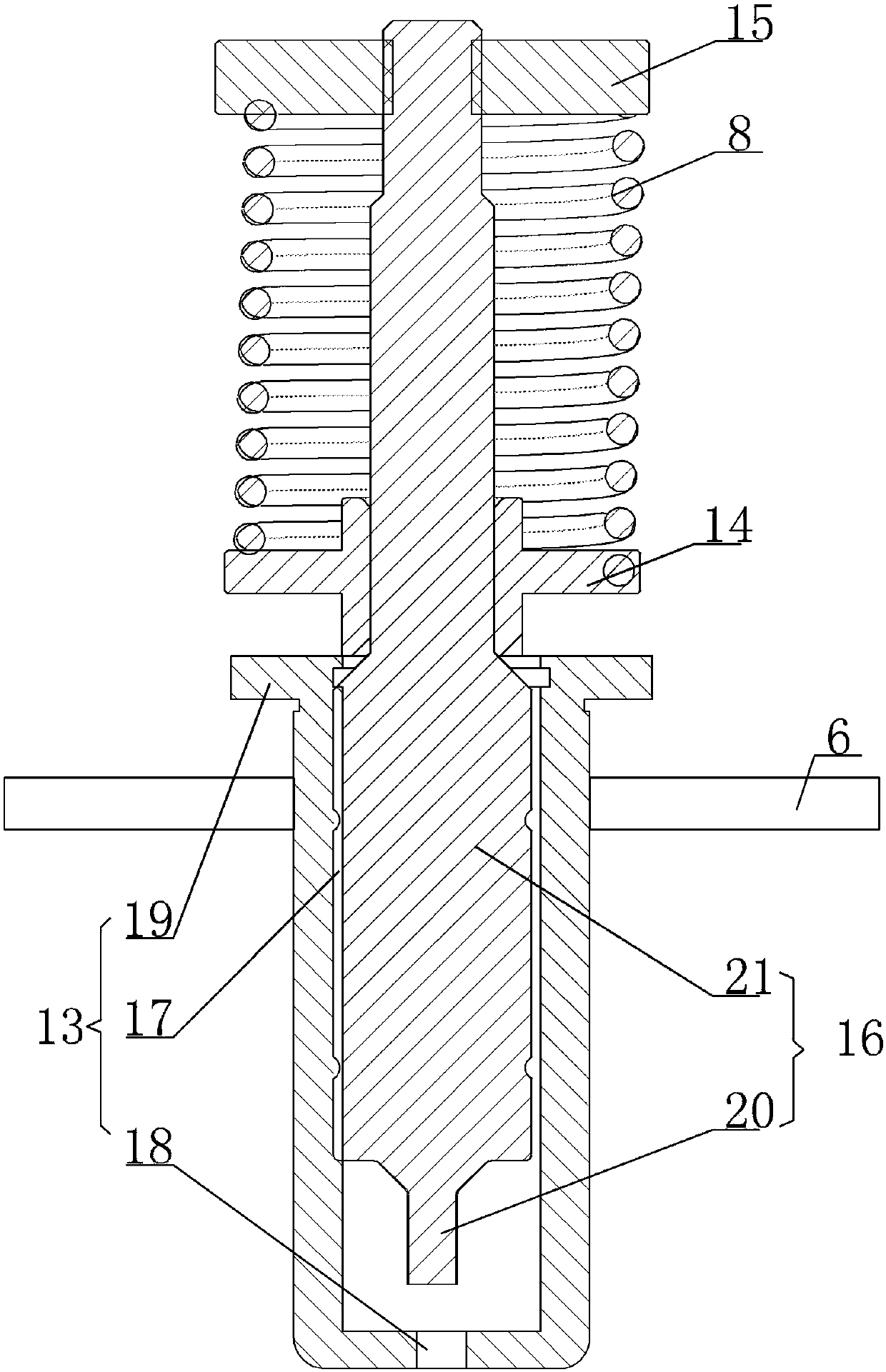

[0013] A copper bar punching die, see figure 1 , figure 2 : It includes a lower mold base 1, a lower supporting plate 2, and a lower formwork 3, the lower end surface of the lower mold base 3 is supported on the center position of the upper end surface of the lower mold base 1, and the lower supporting plate 2 is respectively arranged at both ends of the lower mold base 1 , the lower template 3 is provided with a lower mold knife edge 4, the two sides of the lower template 3 are respectively provided with vertically arranged stripper plates 5, and the two sides of the upper splint 6 are respectively supported and fastened to the stripper plates 5 on both sides The upper surface of the upper clamping plate 6 is provided with a punching tool 7, the top of the punching tool 7 is provided with a linear spring 8 to drive, the punching tool 7 protrudes from the upper clamping plate 6, and the positive part of the downward convex part of the punching tool 7 Below is the lower die e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap