Automobile wheel cover external connection plate

An external connection and wheel cover technology, applied in welding equipment, non-electric welding equipment, edge parts of workpieces, etc., can solve the problems of product surface shrinkage, failure to meet use requirements, shape deformation, etc., to prevent warping and good practicability , to ensure the effect of the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

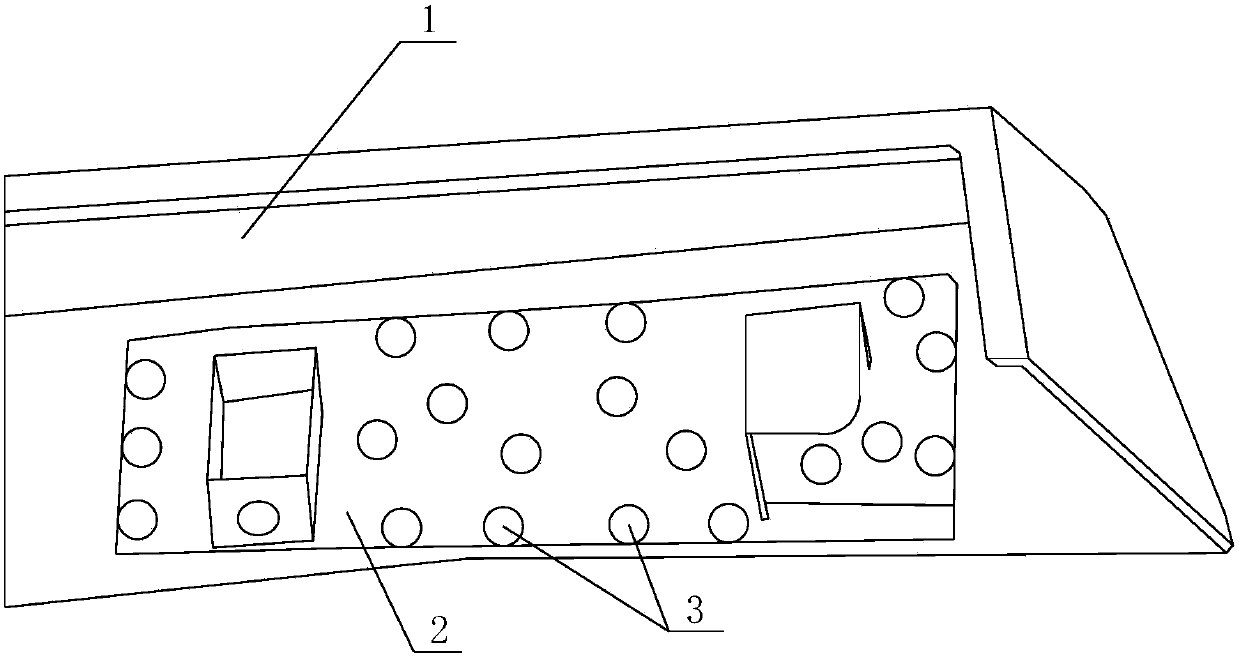

[0012] Such as figure 1 As shown, the present invention provides a kind of automobile wheel house outer connecting plate, and described automobile wheel house outer connecting plate is positioned at the side of car door, comprises exterior decorative plate 1 and welding support 2, and described welding support 2 is positioned at the back side of exterior decorative plate 1 , the welding bracket 2 is connected to the exterior trim panel 1 by ultrasonic welding, and a plurality of ultrasonic welding spots 3 are formed on the welding bracket 2 . By dividing the outer connecting plate of the automobile wheel house into two parts and connecting them by ultrasonic welding, the traditional one-time injection molding is replaced, and the shrinkage phenomenon on the surface of the outer connecting plate of the automobile wheel house is avoided, thereby ensuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com