Integrated machine for cutting and chamfering flow collection pipe

A manifold and all-in-one machine technology, which is applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, maintenance and safety accessories, etc., can solve problems such as low operation accuracy, increased handling steps, and slow operation speed, so as to increase benefits , Save labor and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

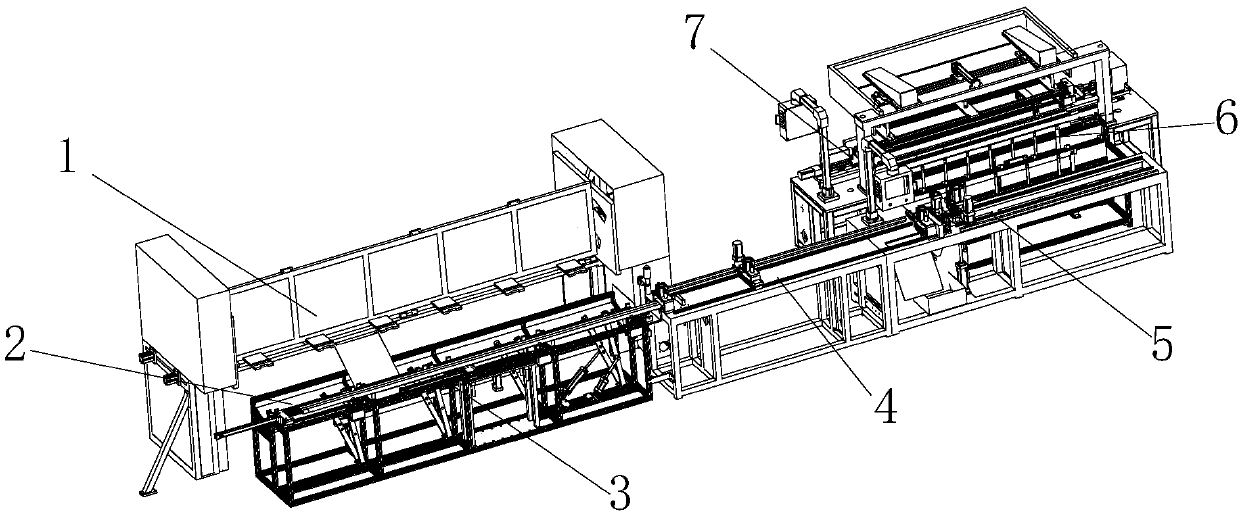

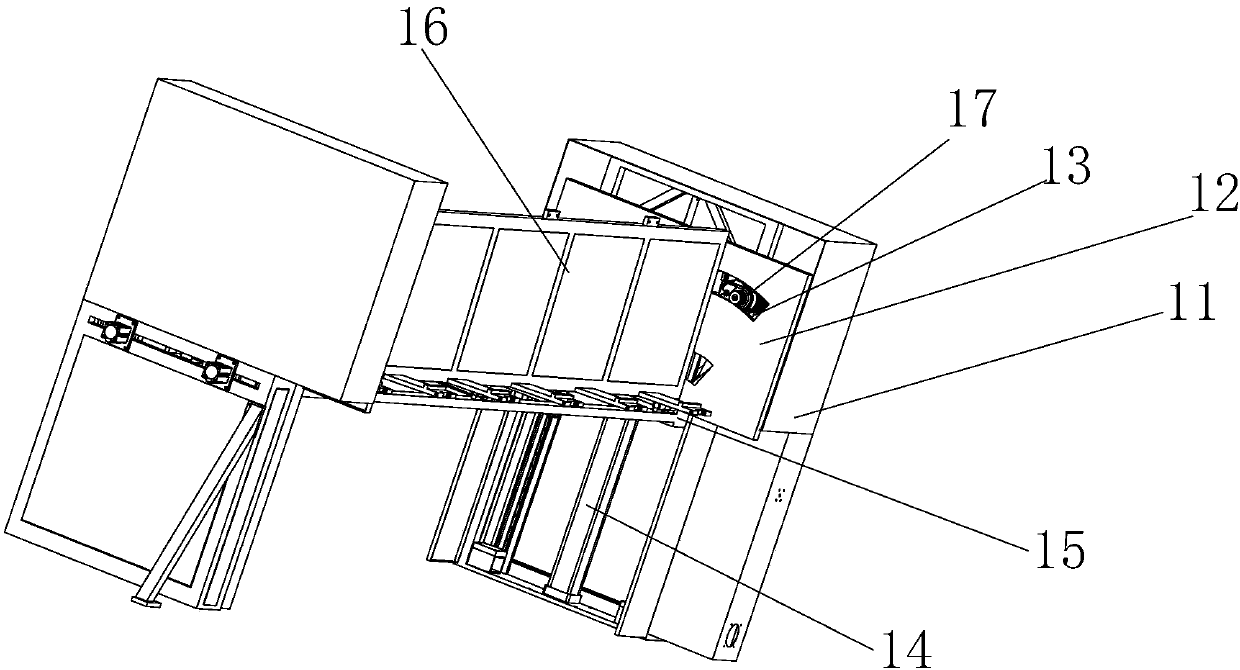

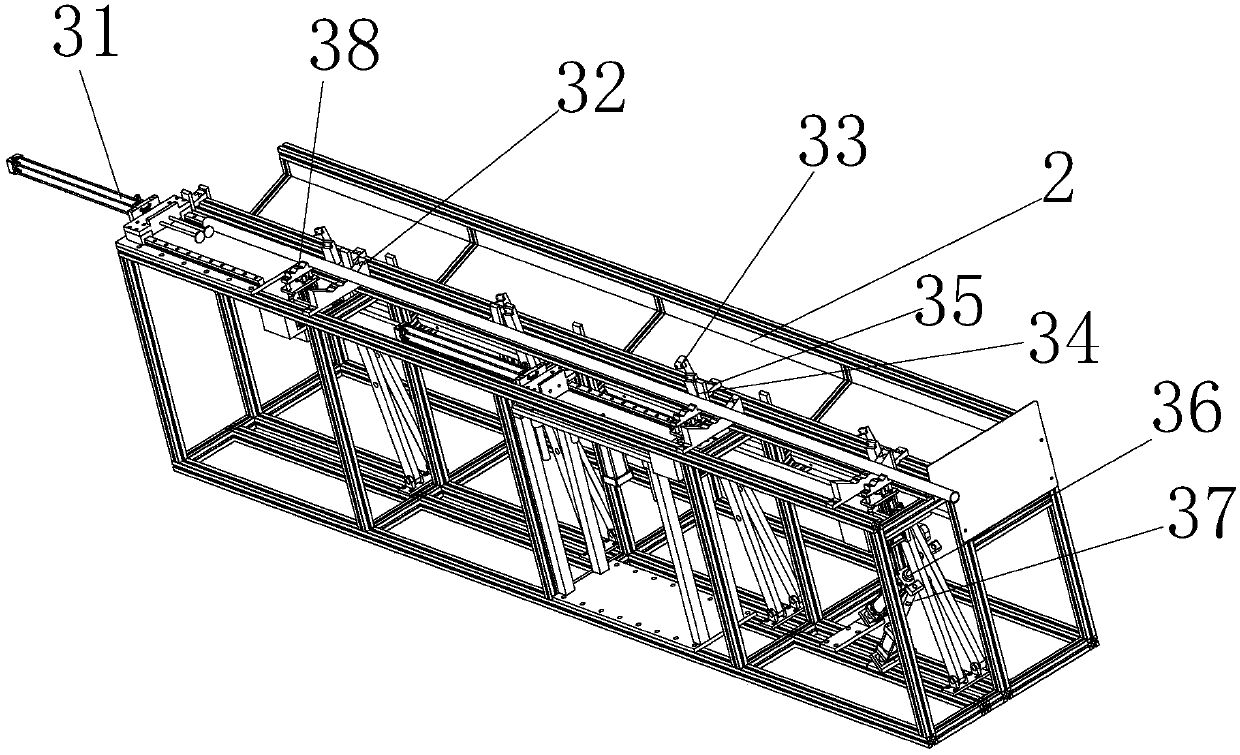

[0027] Such as figure 1 The manifold cutting and chamfering integrated machine shown includes a material rack 3 for placing the manifold, and also includes a feeding mechanism 4 and a shearing and punching mechanism 5. The material rack 3, the feeding mechanism 4 and the shearing The punching mechanism 5 is arranged in turn, and the first material pushing cylinder 31 that pushes the manifold to the feeding mechanism 4 is provided on the side of the material rack 3 away from the feeding mechanism 4, and the material frame 2 is arranged on the side of the material rack 3, The side of the material frame 2 away from the material rack 3 is provided with an auxiliary feeding mechanism 1, and the side of the shearing and punching mechanism 5 is provided with a chamfering device 7, and also includes a chamfering device arranged on the shearing and punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com