Fabricated building frame structure unit

A frame structure and prefabricated technology, which is applied to building components, building structures, buildings, etc., can solve problems such as the decrease of node reliability, and achieve the effects of increasing prefabrication rate, reducing earthquake force, and saving social resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

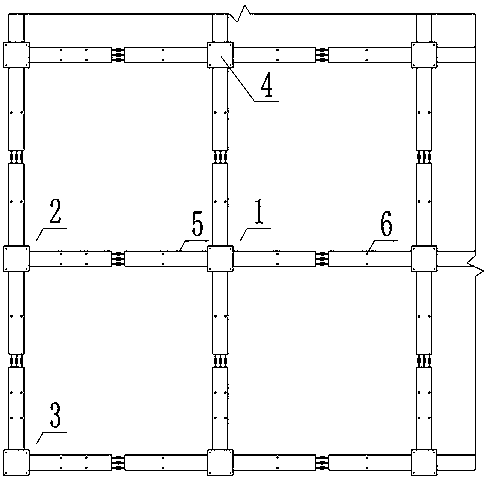

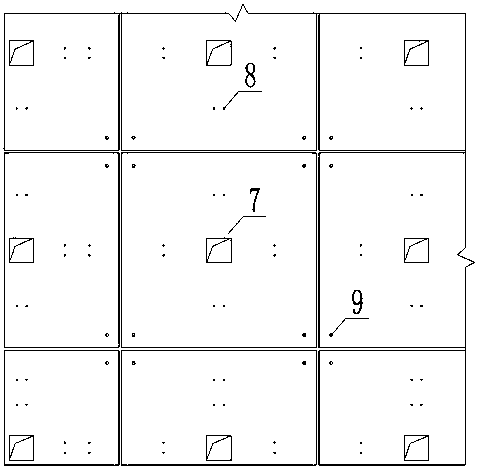

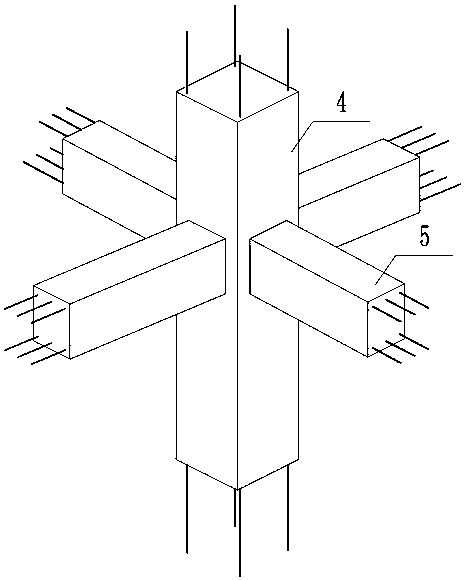

[0020] 1. A prefabricated building frame structure unit, comprising a prefabricated middle three-dimensional beam-column unit 1, a side three-dimensional beam-column unit 2, a corner three-dimensional beam-column unit 3, a prefabricated floor unit, a plate-beam-column connecting device 11, and a corresponding beam unit 5 Concrete is poured after the longitudinal reinforcements are connected to each other. The inside of the slab-column connection part in the slab-beam-column connection device 11 coincides with the special-shaped section of the column unit 4, and the outside coincides with the slab-column installation hole 7 of the prefabricated floor slab unit. The slab-beam-column The lower backing plate of the connection device 11 is placed on the top surface of the beam unit 5, and the prefabricated floor unit is installed from the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com