Universal limestone pipeline distributor

A pipeline distributor, limestone technology, applied in branch pipelines, pipes, pipes/pipe joints/pipes and other directions, can solve the problems of difficult to achieve uniform feeding of pipelines, many pipeline elbows, and large pipeline resistance, etc. Achieve the effect of realizing leap-forward changes, prolonging service life, and being less restricted by site conditions

Inactive Publication Date: 2018-03-13

江苏纽普兰能源环境科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For a single pipeline to enter multiple boiler furnace inlets, it can only be realized through multiple pipeline distributions, which will inevitably result in many pipeline elbows, large pipeline resistance, and difficult layout.

When the number of boiler furnace inlets is odd, it is difficult to achieve uniform feeding of pipelines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0018] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

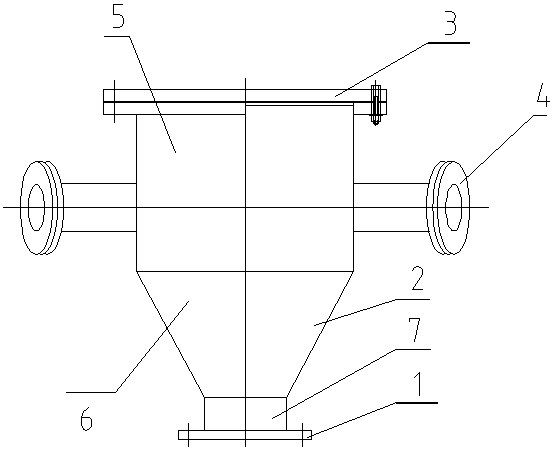

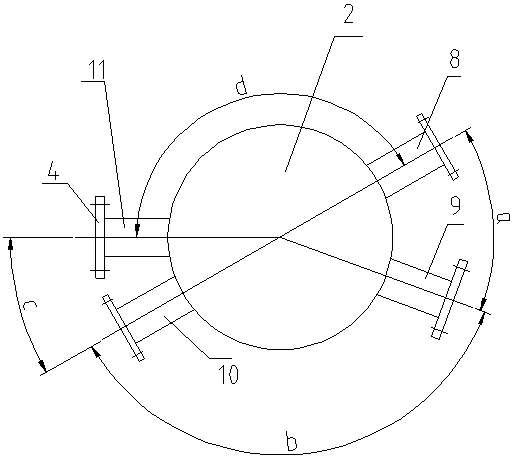

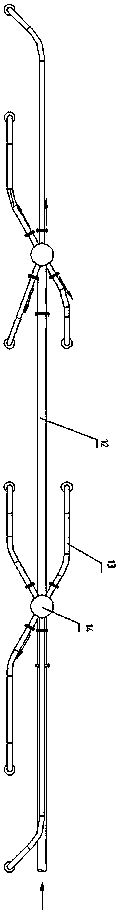

The invention relates to a universal limestone pipeline distributor, which includes an inlet flange, a cylinder body, a top cover and an outlet flange. The body is a cylindrical structure, the lower cylinder is a frustum-shaped structure, the bottom of the lower cylinder is provided with an inlet pipe, the inlet flange is fixed on the inlet pipe, and the outer wall of the upper cylinder is provided with a first outlet pipe in a clockwise direction. , the second outlet pipe, the third outlet pipe and the fourth outlet pipe, an outlet flange is respectively fixed on the first outlet pipe, the second outlet pipe, the third outlet pipe and the fourth outlet pipe, and the top cover is detachable Fixed on the top of the upper cylinder, it can realize the pipeline from one to two, from one to three, and from one to four at one time; after the distribution of pipelines, the layout is flexible, and the limitation of site conditions is small, and the multi-pipelines can be evenly fed.

Description

technical field [0001] The invention relates to a universal limestone pipeline distributor, which is applied to the limestone conveying process pipeline of the dry desulfurization system in the furnace of a CFB unit. Background technique [0002] Circulating fluidized bed (CFB) boiler is a clean combustion technology that develops rapidly and is widely used. It can achieve low SO2 emission by adding limestone to the furnace. Since CFB boilers can achieve clean combustion of fuel, they have been rapidly developed around the world. At present, the research level of CFB technology in China is also in the forefront of the world. [0003] One of the great advantages of CFB boiler technology is the desulfurization in the furnace by spraying limestone powder directly into the furnace. Compared with conventional pulverized coal boiler tail flue gas desulfurization (FGD), this desulfurization system is simple, occupies a small area, and the system is stable and reliable in operation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L41/03

CPCF16L41/004F16L41/03

Inventor 虞永川李叶凡张凯卿洪坤郑庆喜詹胡琴

Owner 江苏纽普兰能源环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com