Tubular motor and control method

A technology for tubular motors and casings, which is applied in the direction of controlling mechanical energy, connecting with control/drive circuits, and electromechanical devices. It can solve the problems of troublesome setting of limit, inconvenient use, and high cost of mechanical limit, and eliminate the number of turns. Record error, easy to use, ingenious and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

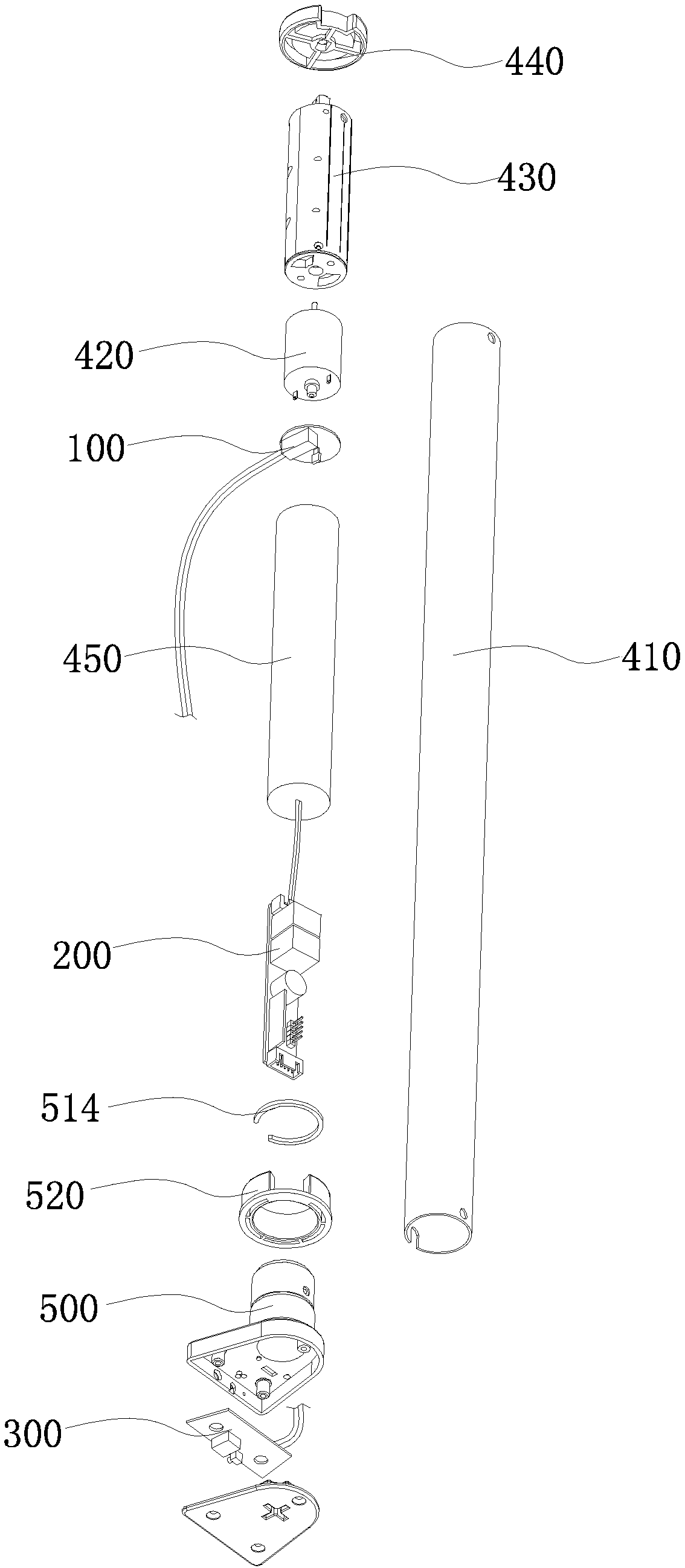

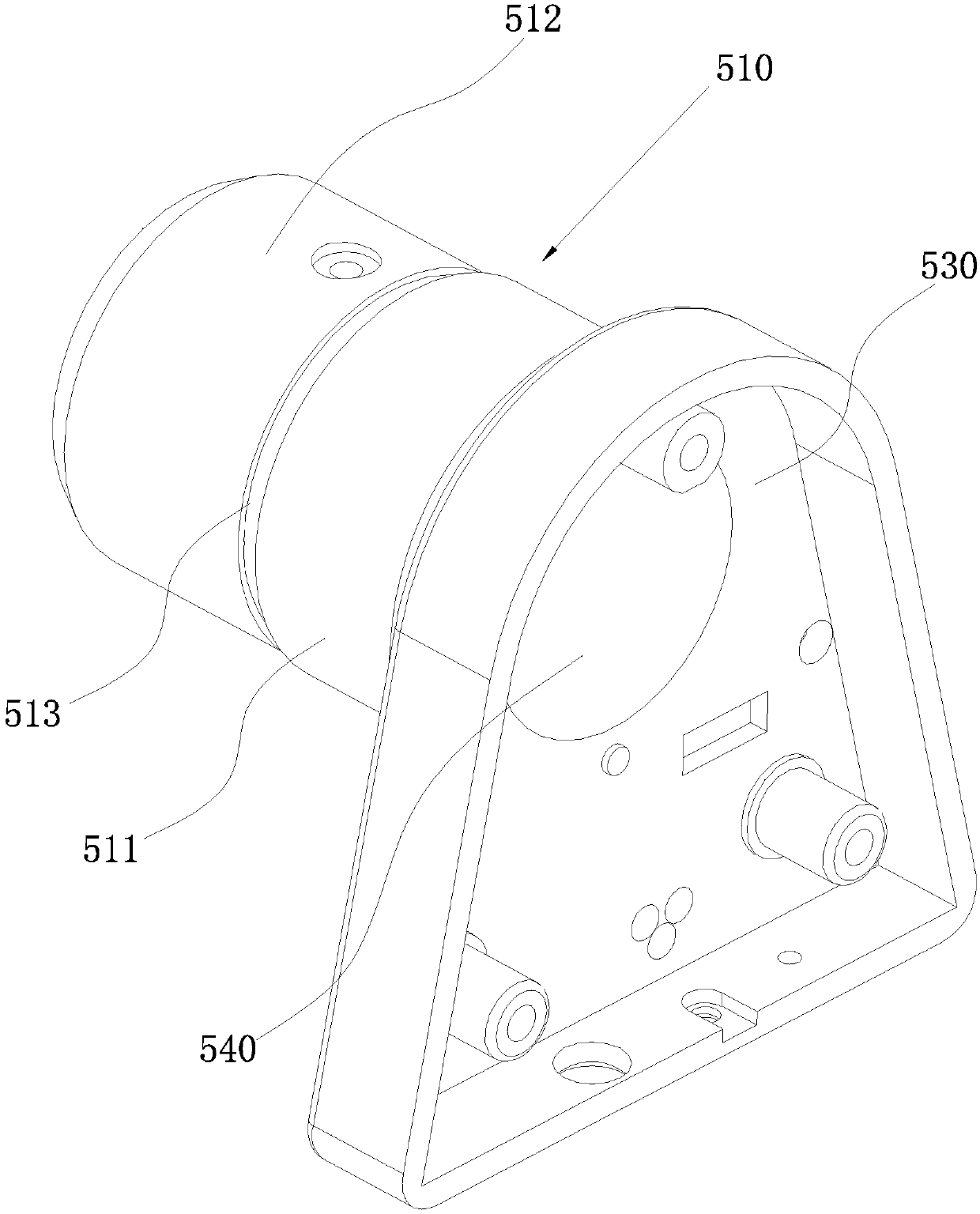

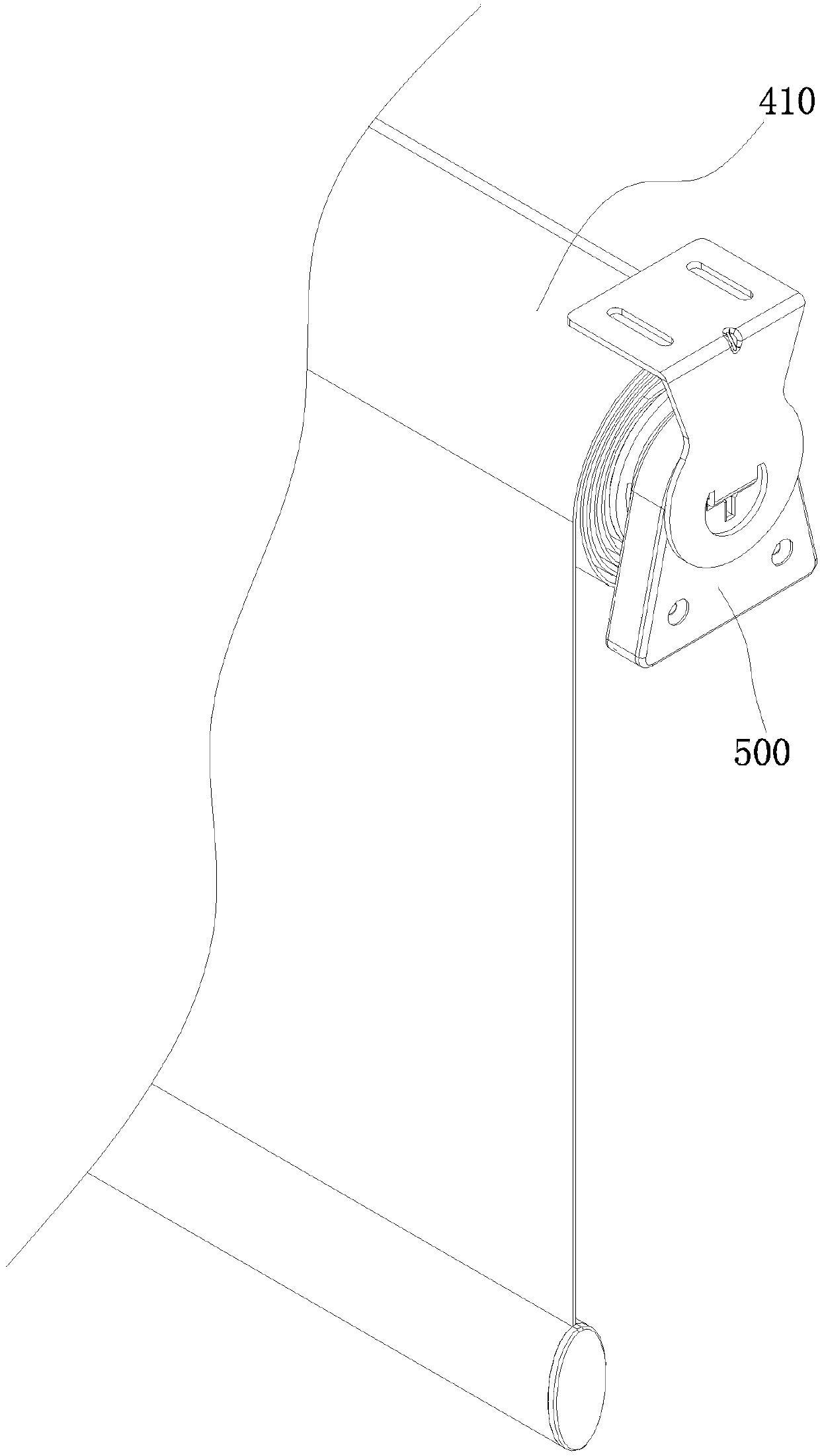

[0031] like figure 1 , figure 2 , Figure 4 As shown, a tubular motor includes: a driving mechanism, a circuit board module 100 and a logic board module 200. It is worth noting here that the motor can realize the functions of intelligent operation and limit automatic stop.

[0032] Wherein, the driving mechanism is used to drive the curtain cloth to be rolled up; the driving mechanism can drive the curtain cloth to be folded or unfolded, and further, it is to drive the curtain roller tube to rotate clockwise or counterclockwise.

[0033] The circuit board module 100 is a circuit board or an inductive element with an induction circuit, which is electrically connected to the drive mechanism to sense the number of motions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com