Vacuum glass rotary sealing processing device

A processing device and vacuum glass technology, which is applied in the field of vacuum glass rotary sealing processing devices, can solve the problems of high technical requirements for operators, time-consuming and labor-intensive problems, and achieve the effects of reliable and ingenious structure, convenient sealing, and high sealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

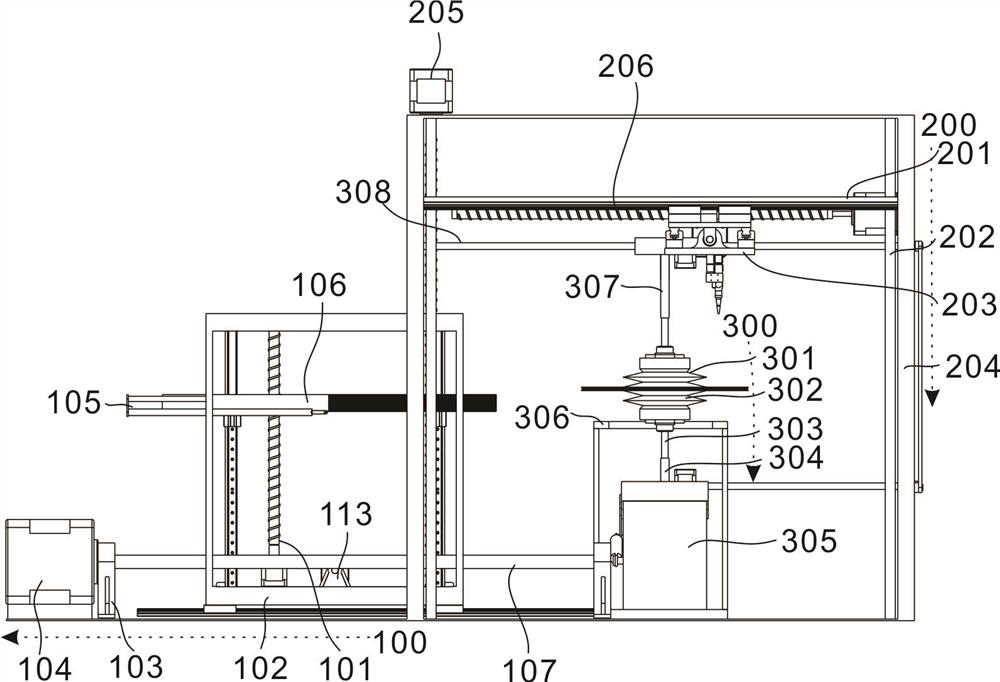

[0037] refer to Figure 1 to Figure 11 , is the first embodiment of the present invention, which provides a vacuum glass rotary sealing processing device, which can realize the side sealing of two pieces of flat glass, and the sealing is more convenient, fast and reliable.

[0038] A vacuum glass rotary sealing processing device, which includes a processing connection assembly 200, the processing connection assembly 200 includes a bottom plate 211, a fixed frame 204 is fixed on the upper side of the bottom plate 211, and the fixed frame 204 is connected with a device that can be lifted and moved in the left, right, front and rear directions. The moving sealing processing connection seat 203, the downward side of the sealing processing connection seat 203 is connected with the solder spray head 212 and the laser generator 213, and the two ends of the fixed frame 204 are provided with arc-shaped position adjustment slide rails 207, A position adjustment chute 207a is provided on...

Embodiment 2

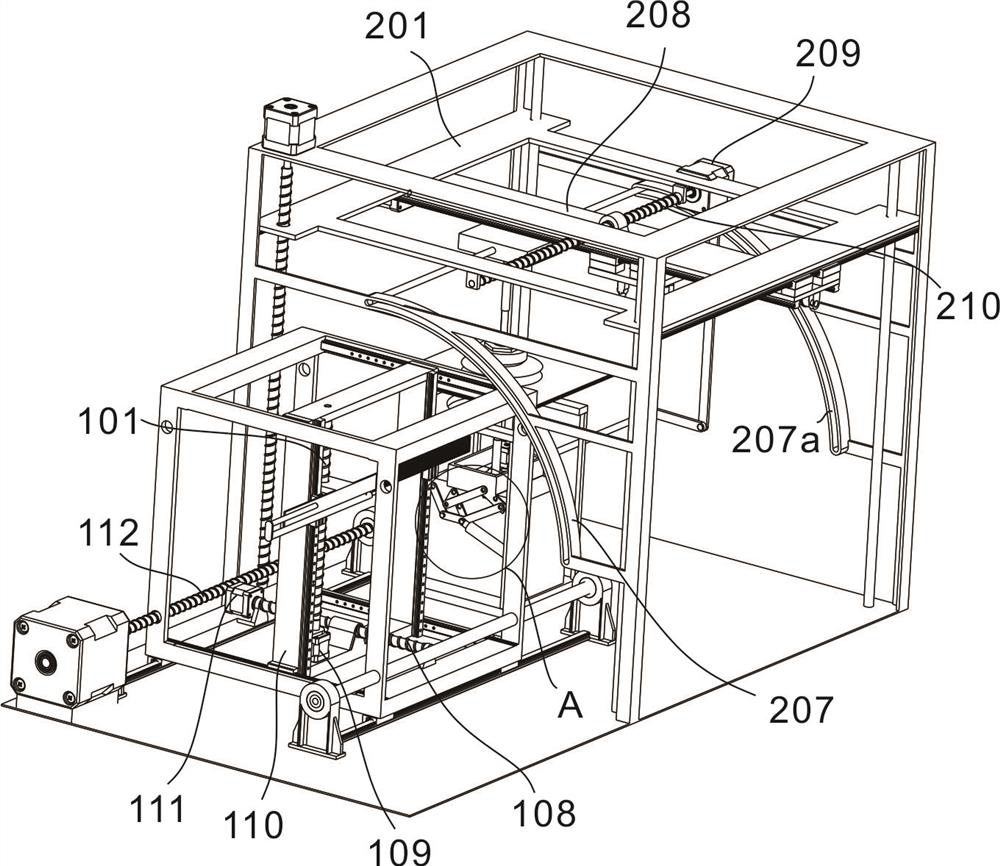

[0051] refer to figure 1 and figure 2 , is the second embodiment of the present invention, which is different from Embodiment 1 in that it can realize the automatic insertion of the glass spacer 500 .

[0052] A vacuum glass rotary sealing processing device, the structure to realize the movement of the moving bar 106 in the left and right direction is specifically: the upper side of the bottom plate 211 is fixedly connected with the first glass 700 spacers 500 installed at intervals in the length direction. The motor 104 and the second A support seat 119, the connecting frame 102 is threadedly connected with a first position adjusting screw 112, one end of the first position adjusting screw 112 is connected with the first glass 700 spacer 500 installation motor 104, the first position adjusting screw 112 The other end is rotatably connected to the first support base 119, and the upper side of the bottom plate 211 is also fixedly connected with two second support bases 103 ar...

Embodiment 3

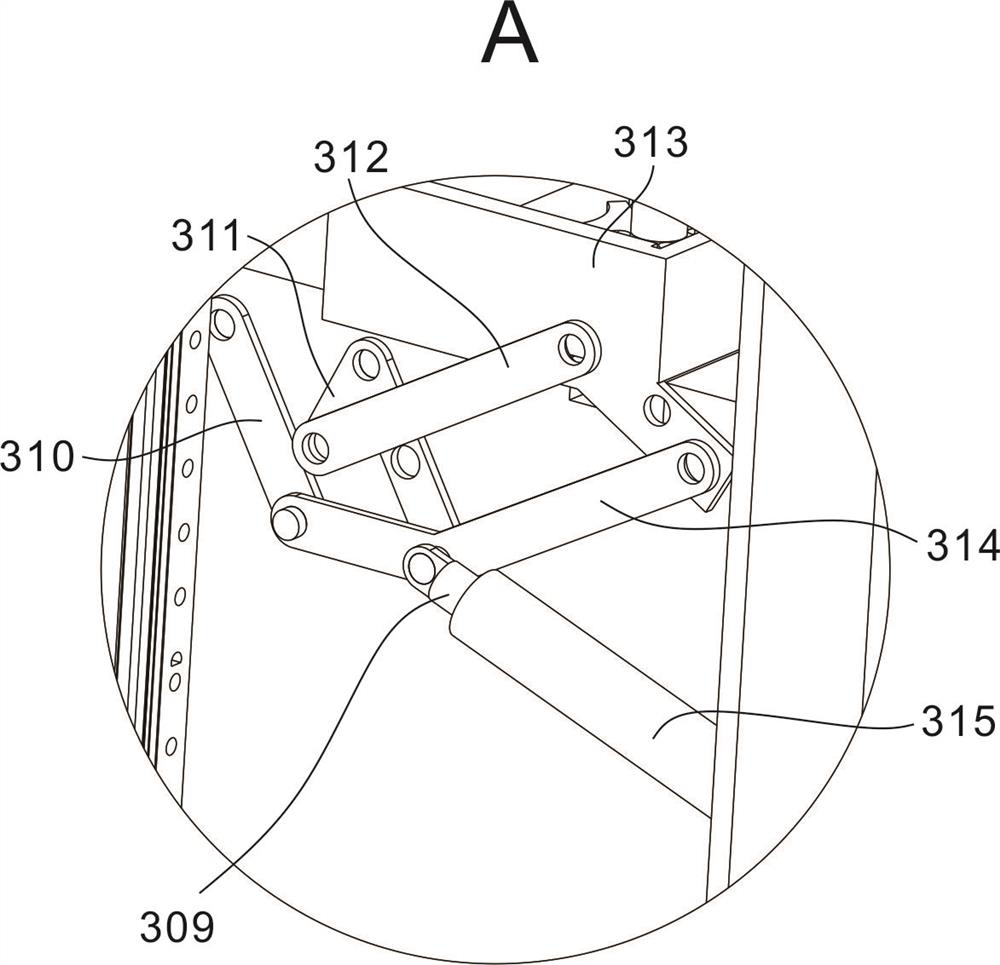

[0059] refer to Figure 4 , Figure 7 and Figure 9 , is the third embodiment of the present invention, which is different from Embodiment 1 or 2 in that it can realize the position adjustment and automatic movement of the solder nozzle 212 and the laser generator 213 .

[0060] A vacuum glass rotary sealing processing device, the structure for realizing the position adjustment of the sealing processing connection seat 203 is specifically that a second height adjustment motor 205 is connected to the upper side of the fixed frame 204, and a second height adjustment motor 205 is connected to a second height adjustment motor 205. To adjust the screw, three vertical guide rods 202 are arranged on the fixed frame 204, and the height adjustment plate 201 is slidably connected to the three vertical guide rods 202, and the second height adjustment screw is screwed on the height adjustment plate 201 One end of the height adjustment plate 201 facing down is slidably connected with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com