Centrifugal switch

A centrifugal switch and centrifugal block technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems of poor accuracy and achieve the effects of reasonable structure, sensitive speed signal transmission, and sensitive signal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

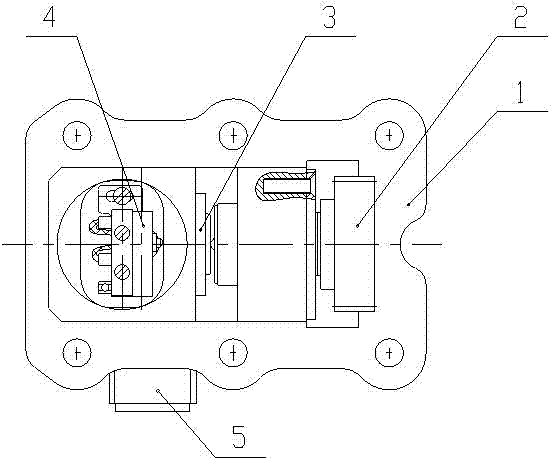

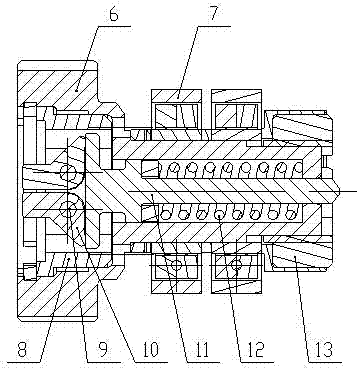

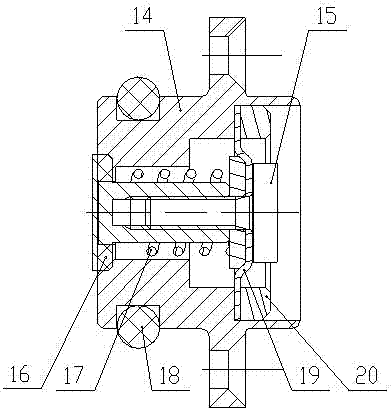

[0014] Example 1. Such as figure 1 As shown, it mainly includes a casing 1 and a centrifugal assembly 2 installed in the casing 1, a pressure rod assembly 3, a micro switch 4 and an electrical connector 5. The casing 1 is a structural part, and all components are installed in it. Its shape should be considered in the installation interface of the starter. The centrifugal assembly 2, the pressing rod assembly 3, the pressing rod assembly 3 and the micro switch 4 are installed on the same axis of the housing 1. When working, the centrifugal assembly 2 acts on the pressing rod assembly 3, and the pressing rod assembly 3 acts on the micro switch 4 , the contacts of the micro switch 4 are connected to the two terminals on the electrical connector 5 . When the micro switch 4 is triggered, the internal reed changes, the circuit is connected, and a signal is sent. Such as figure 2 As shown, the centrifugal assembly 2 includes a gear shaft 6, a centrifugal block 10 and a push ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com