A stator armature test system and test method

A test system and armature technology, which is applied in the field of immersion liquid cooling stator armature test system, can solve problems such as increasing cost, and achieve the effects of reducing test cost, ingenious and reliable structure, and meeting performance test requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

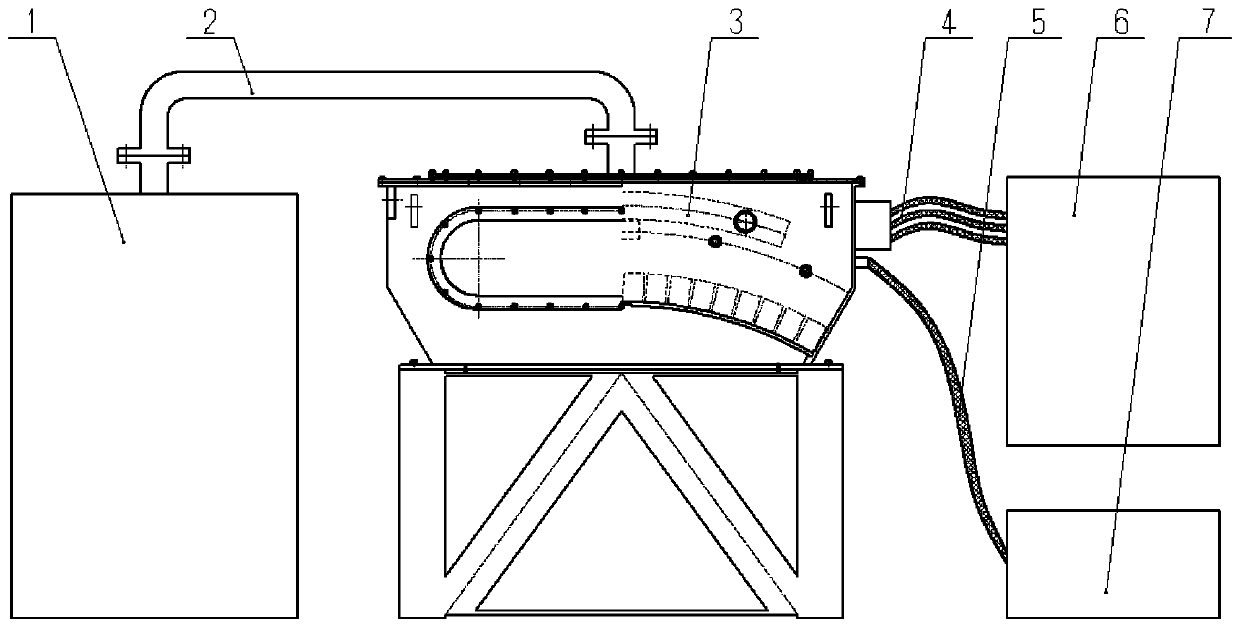

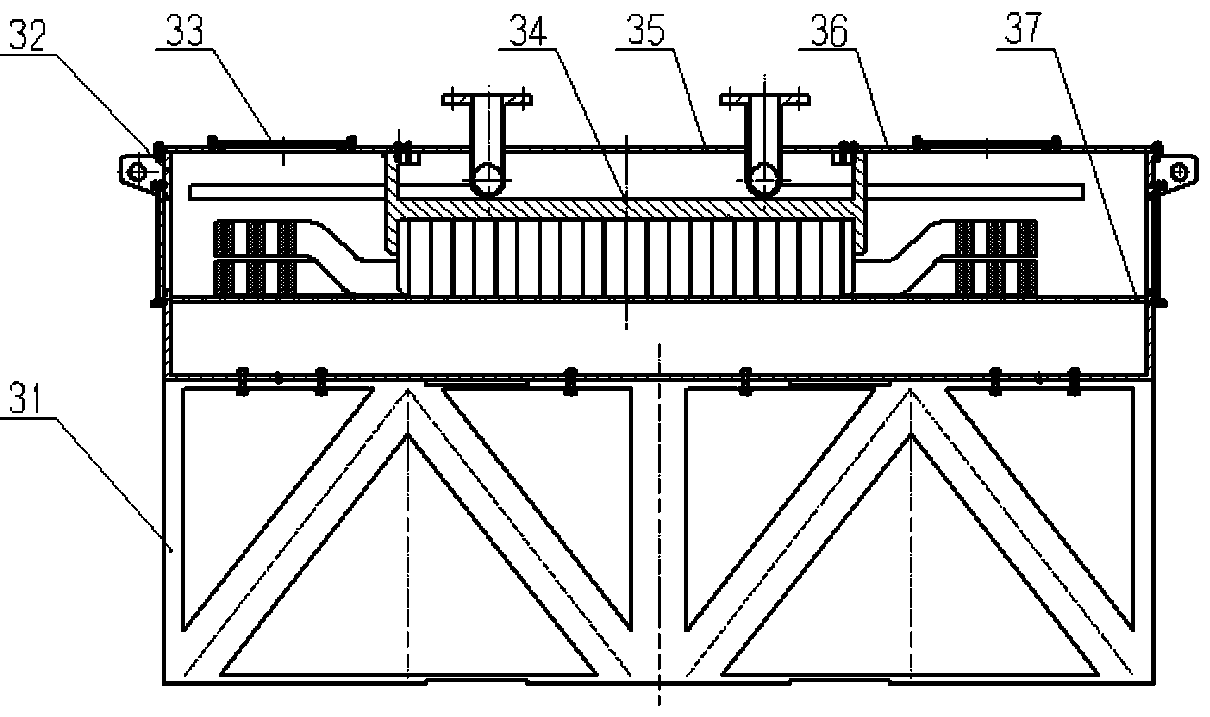

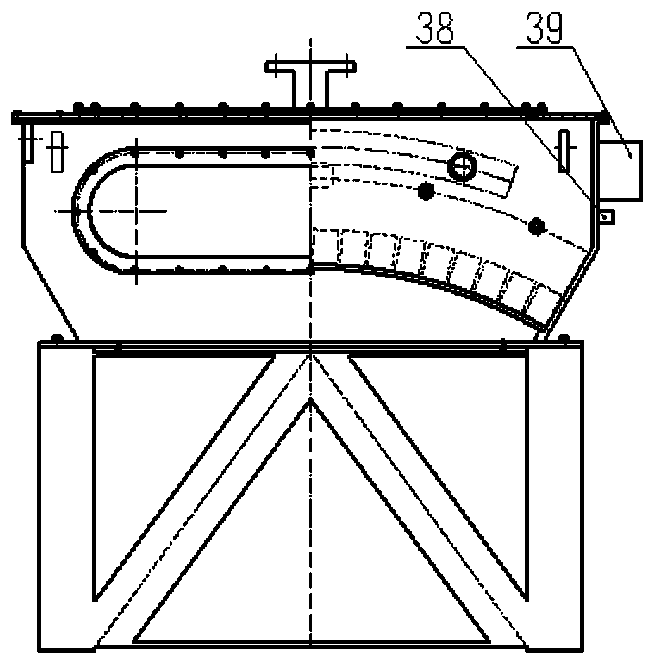

[0034] Such as Figure 1 to Figure 9 As shown, the present invention combines the actual working state of the immersion liquid cooling stator armature, in order to simplify the test device and reduce the test cost, provide a performance test system and test method of the stator armature, which can meet the immersion liquid environment, The temperature rise and strain assessment requirements of the stator armature consist of a pair of pole stator armature test device 3, a cooling liquid circulation system 1, a stator armature to be tested 34, a frequency converter 6, a test system 7, pipelines 2, cables 4, Test leads 5 etc.; the cooling liquid circulation system 1 provides circulating cooling liquid for the stator armature test device 3 through the pipeline 2; Box frame 32 of observation window 331, 1# cover plate 33 with sealing groove and observation window, 2# cover plate 35, 3# cover plate 36 with sealing groove and observation window, non-magnetic arc plate 37, seal Aviat...

Embodiment 2

[0041] The difference from the above embodiments is that the non-magnetic arc plate 37 is made of stainless steel and welded with the frame 32 around.

Embodiment 3

[0043] The difference from the above-mentioned embodiments is that: the insulating bottom plate 391 is made of bakelite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com