superstructure

A vehicle body and bending technology, which is applied to the superstructure, superstructure sub-assemblies, vehicle components, etc., can solve problems such as rising costs, reduce the weight of the vehicle body, and improve the torsional rigidity and side impact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

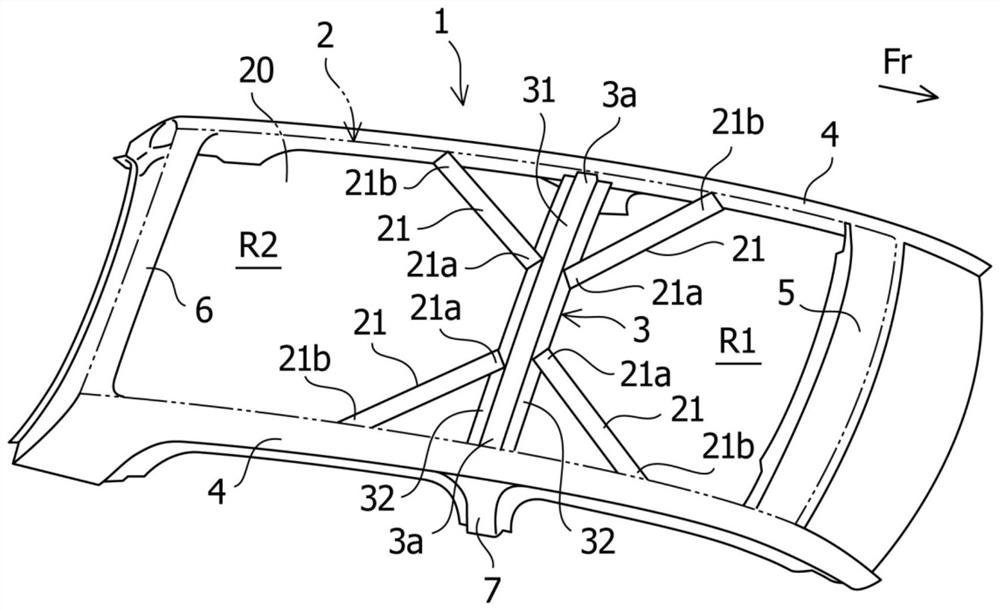

[0022] figure 1 and figure 2 Both show the vehicle body superstructure according to the first embodiment of the present invention.

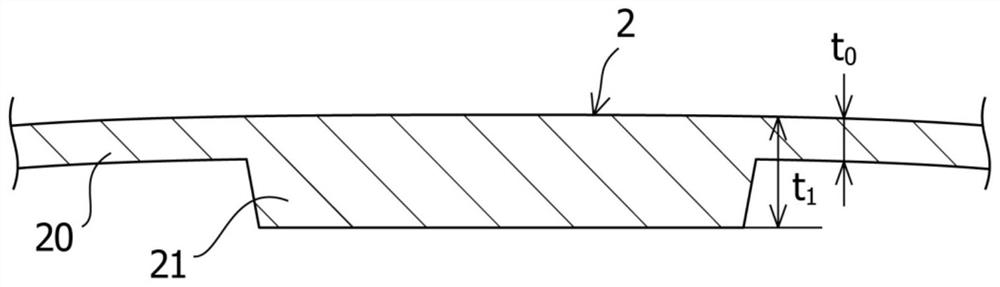

[0023] Such as figure 1 and figure 2 As shown, the upper vehicle body 1 of the vehicle to which the structure according to the first embodiment of the present invention is applied mainly includes a resin roof 2, a roof cross member 3 extending in the vehicle width direction, Extended roof rails 4 located on the left and right sides, and roof front rails 5 and roof rear rails 6 extending in the vehicle width direction at the front and rear ends of the vehicle body, respectively. The resin roof 2 is a resin plate or the like for reducing the weight of the vehicle body. The resin roof 2 is the peripheral parts of the roof rails 4 located on the left and right sides of the vehicle body upper part 1 and the roof front beam 5 and the roof rear beam 6 respectively located at the front and rear ends of the vehicle body upper part 1, and is arrang...

no. 2 approach

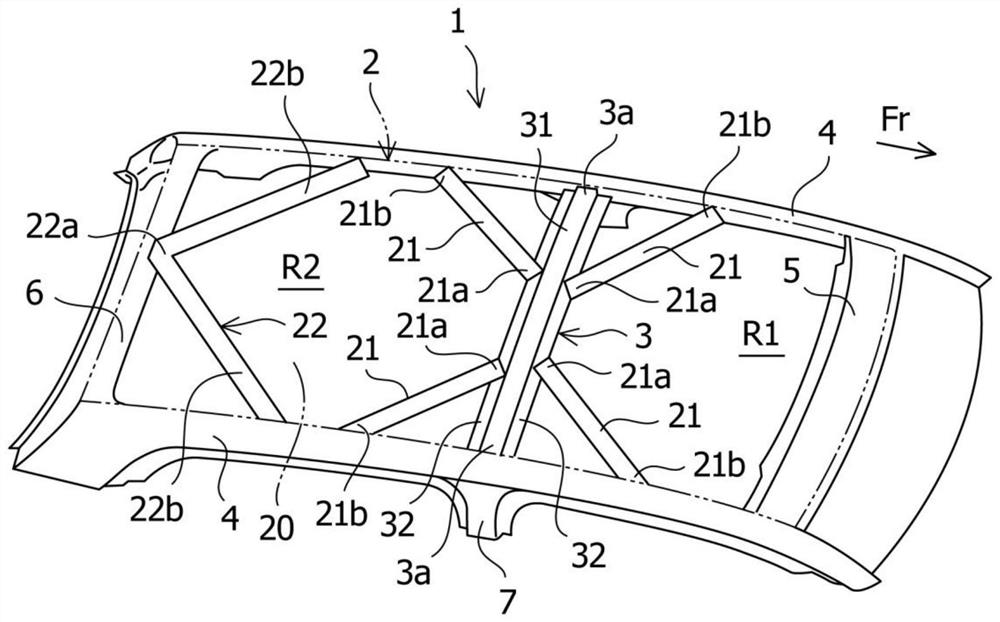

[0039] image 3 A vehicle body superstructure according to a second embodiment of the present invention is shown. The same parts as those described in the above-mentioned first embodiment are denoted by the same reference numerals, and description thereof will not be repeated.

[0040] In the vehicle body upper part 1 according to the second embodiment, in addition to the structure according to the first embodiment, as image 3 As shown, a highly rigid portion 22 that joins the roof rear rail 6 with the respective roof rails 4 on the left and right sides is also disposed on the rear end side in the vehicle rear region R2. The high-rigidity portion 22 on the rear end side includes a beam engaging portion 22a at which the roof rear rail 6 is engaged and a side beam engaging portion 22b extending in an oblique direction toward the vehicle front and at the beam engaging portion 22b. The junction part 22a is branched into a corresponding one of the roof rails 4 extending to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com